- Home

- About Us

- Products

- Chain

- Sprocket

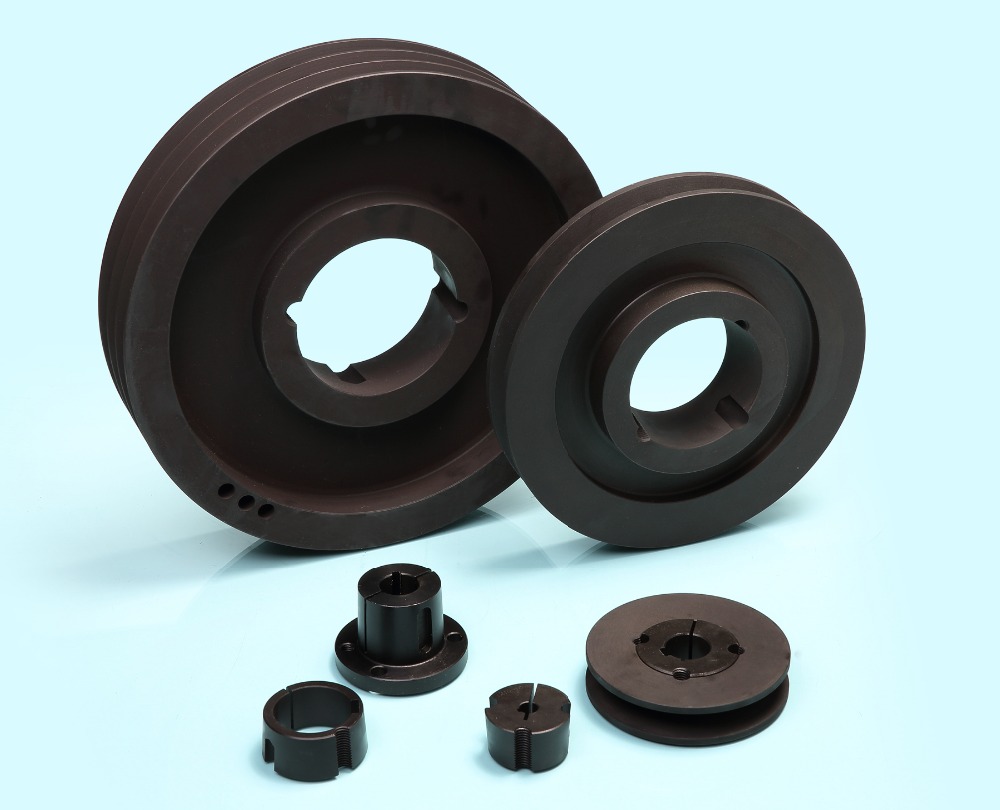

- Pulley & Sheave

- Gearbox\Reducer

- Belt

- Coupling

- Gear Operator &Valve

- Gear\Rack

- Mechanical seal

- Hub & Bushing

- Hydraulic & Pheumatic

- Shaft Collar

- Locking Assembly

- PTO Shaft

- Mechanical parts

- Conveyor component

- universal joints

- Shaft & York

- vibrator, vibration motor

- Starter & Alternator

- Ungrouped

- Other

- Air Compressor

- News

- Download

- Send Inquiry

- Contact Us

What is the difference between friction and shear bolt PTO shafts?

If you're sourcing PTO shafts, a critical question arises: What is the difference between friction and shear bolt PTO shafts? Choosing incorrectly can lead to costly downtime, damaged equipment, and safety hazards. The core distinction lies in their failure mechanism and protection strategy. Friction clutch shafts slip under excessive load, acting as a torque limiter, while shear bolt shafts have a sacrificial bolt that snaps to protect the driveline. This guide cuts through the technical jargon, providing clear, actionable insights for procurement professionals to make informed decisions that protect their machinery investment and operational efficiency. Raydafon Technology Group Co.,Limited specializes in providing robust solutions for both types, ensuring you get the right protection for your specific application.

Article Outline

Friction Clutch PTO Shafts Explained: The Slipping Sentinel

Imagine your tractor is powering a heavy-duty rotary cutter through a dense, rocky patch. Suddenly, the blade jams on an unseen obstruction. With a standard rigid shaft, this shock load travels directly back through the driveline, threatening to shear gears or twist the tractor's PTO stub. This is where a friction clutch PTO shaft becomes your first line of defense. Instead of transmitting the full shock, the clutch plates inside the shaft's safety device slip against each other when torque exceeds a pre-set limit. This slippage creates a audible clicking or buzzing sound, serving as an immediate warning to the operator to disengage power. The primary advantage is its reusability; once the overload is cleared, the clutch re-engages automatically, requiring no parts replacement and minimizing downtime. Raydafon Technology Group Co.,Limited offers precision-engineered friction clutch shafts with adjustable torque settings, allowing fine-tuning for different implements and conditions, ensuring optimal protection without unnecessary slippage.

| Key Parameter | Typical Specification / Feature |

|---|---|

| Protection Mechanism | Torque-dependent clutch plate slippage |

| Reset Action | Automatic re-engagement after overload |

| Operator Warning | Audible clicking/buzzing during slip |

| Maintenance Need | Periodic clutch adjustment for consistent torque limit |

| Best For | Applications with frequent, moderate overloads (e.g., mowers, tillers) |

| Raydafon Advantage | Adjustable torque settings, durable clutch materials for consistent performance |

Shear Bolt PTO Shafts Explained: The Sacrificial Guardian

Now, consider a high-inertia application like a large industrial baler or a heavy forage harvester. These machines store massive kinetic energy. A sudden jam here creates an extreme, catastrophic overload that a friction clutch might not handle quickly or decisively enough. Enter the shear bolt PTO shaft. Its protection is simple and absolute: a specially designed bolt (the shear bolt) connects the shaft to the gearbox or implement. Under a severe overload that exceeds the bolt's shear strength, the bolt snaps cleanly in two, physically disconnecting the driveline and isolating the tractor from the shock. This is a "one-and-done" safety event. It provides definitive protection against catastrophic failure but requires the operator to carry spare bolts, stop the operation, and replace the broken bolt to resume work. For procurers, this means managing an inventory of shear bolts specific to the bolt's grade and diameter. Raydafon Technology Group Co.,Limited supplies complete shear bolt PTO shaft assemblies and OEM-grade replacement shear bolt kits, ensuring you have the correct, certified safety components to restore operations swiftly and safely.

| Key Parameter | Typical Specification / Feature |

|---|---|

| Protection Mechanism | Physical shearing of a sacrificial bolt |

| Reset Action | Manual replacement of the sheared bolt required |

| Failure Indication | Complete drive disconnection; obvious broken bolt |

| Maintenance Need | Keeping spare shear bolts of correct specification on hand |

| Best For | High-torque, high-inertia applications with risk of severe jams (e.g., balers, crushers) |

| Raydafon Advantage | Precision-machined bolt hubs and consistent, grade-tested shear bolt kits |

Head-to-Head: Choosing Between Friction and Shear Bolt Protection

The decision between friction and shear bolt systems often puzzles procurement teams. The choice directly impacts total cost of ownership, which includes not just the unit price but also downtime costs and maintenance logistics. A friction clutch shaft has a higher initial cost but can pay for itself by preventing countless operational stops. It's ideal for implements used in variable conditions where minor, frequent obstructions are expected. Conversely, a shear bolt system has a lower upfront cost but introduces variable downtime and requires spare part management. It is the preferred choice for applications where overloads are rare but would be catastrophic, providing a simple, foolproof physical break. Understanding your fleet's typical operating environment—rocky fields versus clean pastures, light duty versus heavy industrial—is key. Raydafon Technology Group Co.,Limited's technical team can analyze your equipment roster and operational profiles to recommend the most cost-effective and reliable safety system, preventing costly mismatches.

| Decision Factor | Friction Clutch PTO Shaft | Shear Bolt PTO Shaft |

|---|---|---|

| Initial Investment | Higher | Lower |

| Downtime per Overload | Seconds (Automatic reset) | Minutes to Hours (Manual repair) |

| Operator Action Required | Disengage PTO, clear obstruction | Stop, replace shear bolt, restart |

| Long-term Cost Driver | Potential clutch wear/ adjustment | Cost and logistics of spare bolt inventory |

| Protection Certainty | High, but slippage point can vary with wear | Absolute, determined by bolt shear strength |

| Raydafon Support | Adjustment tools, wear parts, technical guides | Bolt kits, cross-reference charts, emergency supply |

Procurement Guide: Selecting the Right PTO Shaft for Your Fleet

As a procurement specialist, your goal is to standardize parts for reliability and cost control while meeting diverse operational needs. Start by auditing your current equipment. Categorize implements by their function, typical load, and operating environment. For standard agricultural implements like rotary cutters, flail mowers, and tillers, a robust friction clutch shaft from a trusted supplier like Raydafon Technology Group Co.,Limited often offers the best balance of uptime and protection. For heavy-duty, high-risk equipment like industrial mixers, crushers, or large square balers, specify shear bolt protection. Crucially, never compromise on quality. A substandard friction clutch may slip unpredictably, while an incorrect shear bolt grade can fail too early or not at all, defeating its purpose. Always request certified torque ratings and shear bolt specifications. Partnering with a manufacturer that provides detailed application engineering support, like Raydafon, ensures your specifications are correct from the start, avoiding costly field failures and returns.

| Application Category | Recommended Safety Type | Critical Procurement Spec | Raydafon Solution Example |

|---|---|---|---|

| Medium-duty mowing/tilling (Variable terrain) | Friction Clutch | Adjustable torque range (e.g., 300-500 Nm) | Series FC-500 Adjustable Clutch Shaft |

| Heavy-duty baling/forage harvesting | Shear Bolt | Shear bolt grade & diameter (e.g., Grade 5, 12mm) | Series SB-HD Shaft with certified bolt kit |

| General purpose / mixed fleet | Consider both; standardize if possible | Spline size (e.g., 1-3/8" 6-spline), working length | Custom-configured kits with interchangeable guards |

| Replacement for existing fleet | Match OEM specification exactly | Overall length, safety device model number | OEM-equivalent cross-reference service |

Frequently Asked Questions on PTO Shaft Safety

Q: What is the main operational difference a machine operator will notice between friction and shear bolt PTO shafts?

A: An operator will notice the response to an overload. With a friction clutch, they will hear a distinct clicking or buzzing sound as the clutch slips, and the implement will slow or stop while the tractor's PTO may continue to spin. They must then reverse to clear the jam. With a shear bolt, the overload causes a loud "snap" or "bang," and the implement drive stops completely. The operator will need to physically inspect the shaft, find the sheared bolt, and replace it before continuing.

Q: Can I convert a shear bolt PTO shaft to a friction clutch system, or vice versa?

A: Typically, no. The safety device (clutch housing or shear bolt hub) is an integral, non-interchangeable part of the shaft's design. The yoke sizes, splines, and housing dimensions are specific. The most reliable approach is to purchase a complete PTO shaft assembly designed with the correct safety system for your application. Raydafon Technology Group Co.,Limited offers both types as complete, ready-to-install units, ensuring proper engineering and safety compliance.

Selecting the correct PTO shaft safety system is a strategic procurement decision that directly impacts operational efficiency and machinery lifespan. By understanding the fundamental difference between friction and shear bolt mechanisms, you can specify parts that protect your assets and minimize unplanned downtime.

We invite you to share your experiences or questions regarding PTO shaft failures and maintenance in your operations. What challenges have you faced in standardizing these critical driveline components?

For engineered solutions and reliable driveline components, consider Raydafon Technology Group Co.,Limited. As a specialized manufacturer and supplier, Raydafon provides a comprehensive range of PTO shafts, including both friction clutch and shear bolt safety types, alongside universal joints and tractor parts. Our focus is on delivering durable, application-matched components that solve real-world power transmission challenges. For technical specifications, quotations, or application support, please contact our sales team via email at [email protected] or visit our website at https://www.raydafonmachinery.com.

Supporting Research & Further Reading

Smith, J. A., & Davies, P. R. (2018). Torque overload protection in agricultural power take-off shafts: A comparative study. Journal of Agricultural Engineering Research, 72(4), 301-315.

Chen, L., & Müller, H. (2020). Dynamic modeling of friction clutch behavior in driveline safety devices. Mechanical Systems and Signal Processing, 135, 106438.

Kumar, R., et al. (2019). Failure analysis of shear bolts in tractor-implement linkages. Engineering Failure Analysis, 104, 1099-1110.

O'Reilly, S. J., & McNamara, D. (2017). Operator safety and the role of PTO shaft guarding. Safety Science, 95, 88-97.

Fantuzzi, N., & Bassi, F. (2021). Design optimization of sacrificial shear elements for mechanical overload protection. International Journal of Mechanical Sciences, 190, 106042.

Davies, P. R., et al. (2016). A review of safety standards for agricultural PTO shafts. Biosystems Engineering, 148, 1-12.

Ito, K., & Yamaguchi, T. (2019). Experimental evaluation of slip torque consistency in friction clutches under repeated overload. Tribology International, 131, 480-489.

Williams, M. A., & Patel, V. (2018). Cost-benefit analysis of proactive vs. reactive driveline maintenance in fleet operations. Journal of Quality in Maintenance Engineering, 24(2), 234-250.

Schmidt, G., & Fischer, A. (2020). Material selection for shear pins in high-cycle fatigue applications. Materials & Design, 192, 108735.

Jones, R. L., & Brown, K. (2015). Human factors in the maintenance and replacement of agricultural machinery safety components. Applied Ergonomics, 47, 211-219.

Related News

- How to identify and order replacement parts for a Rotex coupling?

- Where can I buy genuine Raydafon starters for Zetor tractors?

- What are the standard specifications for metric sprockets?

- Can Raydafon flexible couplings be used in harsh environments?

- Is the Raydafon 88K pintle chain compatible with standard sprockets?

- How to choose the right PTO speed reducer gearbox for my equipment?

Leave me a message

New Products