- Home

- About Us

- Products

- Chain

- Sprocket

- Pulley & Sheave

- Gearbox\Reducer

- Belt

- Coupling

- Gear Operator &Valve

- Gear\Rack

- Mechanical seal

- Hub & Bushing

- Hydraulic & Pheumatic

- Shaft Collar

- Locking Assembly

- PTO Shaft

- Mechanical parts

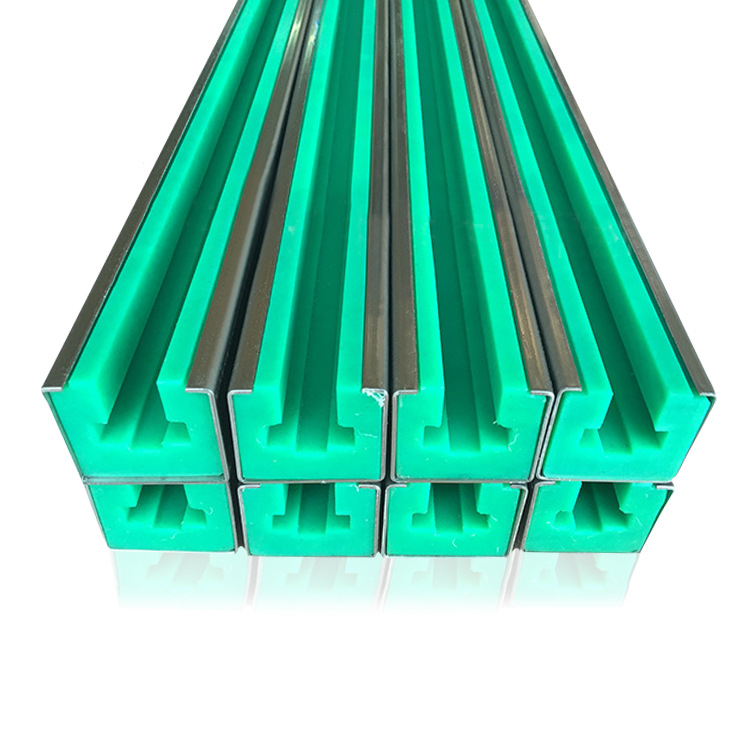

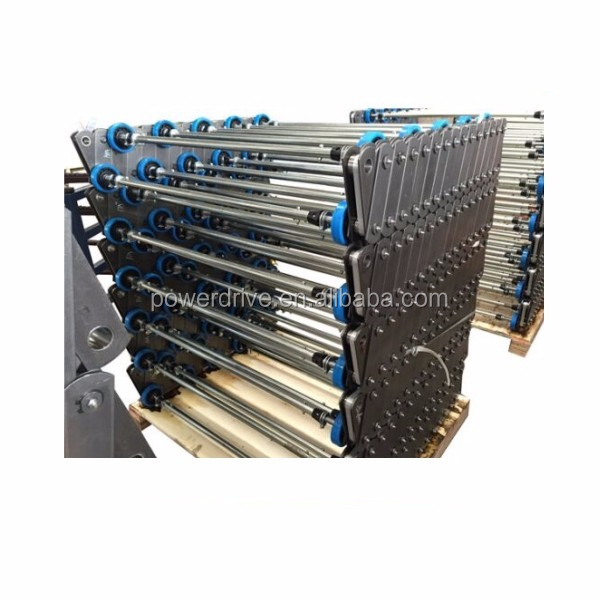

- Conveyor component

- universal joints

- Shaft & York

- vibrator, vibration motor

- Starter & Alternator

- Ungrouped

- Other

- Air Compressor

- News

- Download

- Send Inquiry

- Contact Us

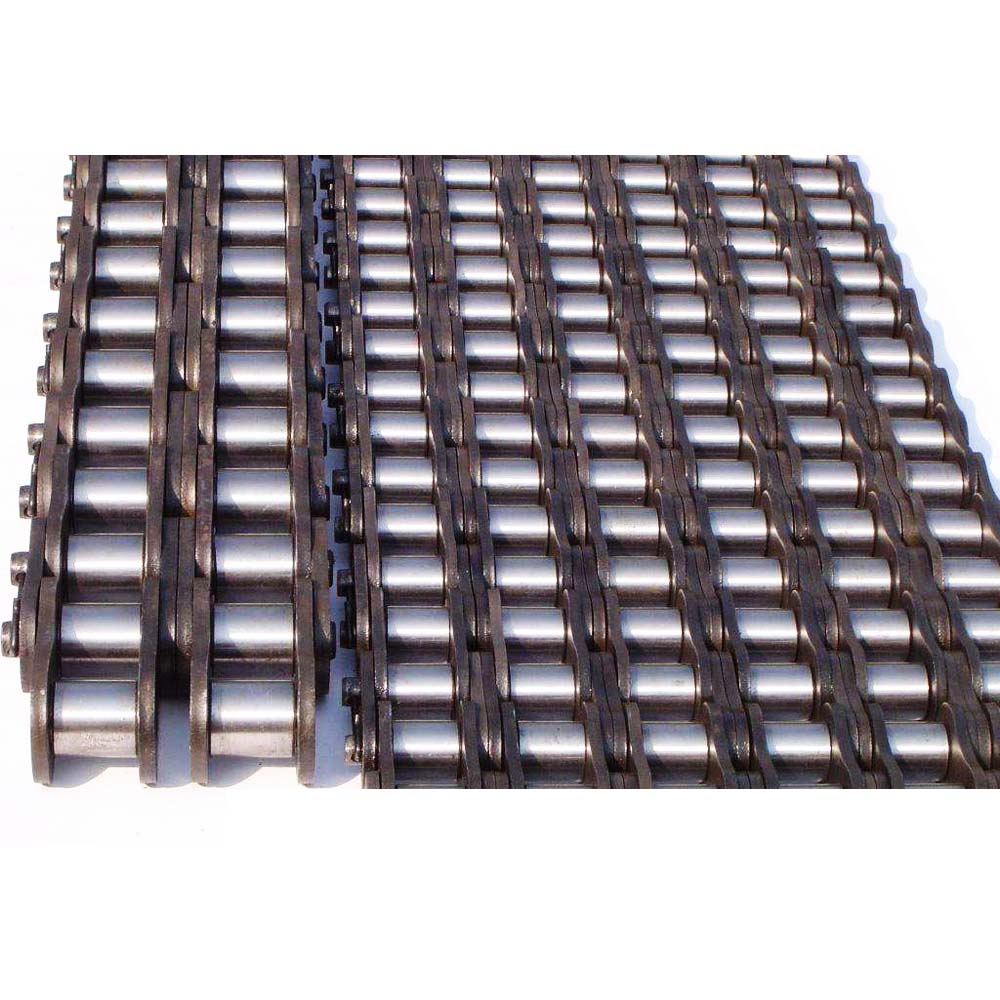

Roller Chain

Raydafon Roller Chains: High-Performance Power Transmission Solutions from China's Leading Manufacturer

For industrial buyers seeking reliable roller chains, quality consistency and rapid availability are critical. Raydafon, a premier China roller chain manufacturer, produces ANSI, DIN, and ISO standard chains for food processing, agricultural machinery, packaging equipment, and industrial automation. As specialized suppliers with full OEM/ODM capabilities, we provide customized roller chain solutions with 15-20 day lead times and competitive wholesale pricing.

Raydafon Roller Chain Product Specifications

Comprehensive Product Line

- ANSI Standard Roller Chains (25 to 240 series)

- DIN/ISO Standard Roller Chains (06B to 48B)

- Heavy Duty Roller Chains (H series with thicker plates)

- Stainless Steel Roller Chains (304/316 grade)

- Specialty Chains (Offset, double pitch, corrosion-resistant)

Technical Specification Comparison

| Parameter | Standard Grade | Precision Grade | Heavy Duty Grade |

|---|---|---|---|

| Material | Carbon Steel | Alloy Steel | Heat-Treated Steel |

| Tensile Strength | 6,000-18,000N | 8,000-24,000N | 12,000-30,000N |

| Hardness | HRC 40-45 | HRC 45-50 | HRC 50-55 |

| Surface Treatment | Zinc Plated | Nickel Plated | Black Oxide |

| Temperature Range | -20°C~150°C | -30°C~180°C | -40°C~200°C |

| Certifications | ISO 606 | ANSI B29.1 | DIN 8187 |

Key Manufacturing Advantages

- Precision Stamping Technology (±0.02mm tolerance)

- Automatic Riveting Systems for consistent pin seating

- 100% Pre-Stretching to minimize operational elongation

- Interchangeable with major brands (Tsubaki, Renold)

Addressing Common Roller Chain Purchasing Challenges

1. Premature Wear and Elongation

Raydafon Solution:

- Induction-hardened pins and bushings

- Pre-lubricated chains with premium grease

- Optional tungsten carbide treatment for abrasive environments

2. Inconsistent Quality from Suppliers

Raydafon Quality Assurance:

- Raw material certification (SGS tested)

- Dimensional checks with optical comparators

- Destructive testing on 5% of production batches

3. Slow Customization Turnaround

Raydafon Advantage:

- Digital pattern library for fast modifications

- Small MOQ (from 100 pieces)

- 10-day rush service for standard modifications

Roller Chain FAQ - Expert Purchasing Guidance

Q1: How do I select the right roller chain size for my application?

A: Consider these key factors:

- Power Requirements: Calculate using horsepower and RPM

- Shaft Sizes: Match sprocket bore dimensions

-

Environmental Conditions: Choose materials/coatings accordingly

Raydafon engineers provide free selection assistance with application details.

Q2: What maintenance practices maximize roller chain lifespan?

A: Implement these best practices:

- Regular Lubrication: Use chain-specific lubricants every 80-100 hours

- Proper Tension: Maintain 2-4% sag between sprockets

-

Alignment Checks: Maximum 0.3° angular misalignment

Our chains include wear indicators for easy monitoring.

Q3: Can you produce chains matching obsolete equipment specifications?

A: Raydafon specializes in legacy system support:

- Reverse engineering from samples

- Recreation of discontinued designs

-

Material upgrades to improve original specifications

Submit samples or drawings for free technical evaluation.

Industry-Specific Solutions

Food Processing Equipment

- FDA-compliant stainless steel chains

- Hygienic designs with smooth surfaces

- CIP (Clean-in-Place) compatible versions

Agricultural Machinery

- Self-cleaning chain designs

- Corrosion-resistant coatings

- High-impact versions for combine harvesters

Packaging Automation

- Low-noise precision chains

- Anti-static versions for electronics handling

- High-speed capable designs (up to 1,500 RPM)

Raydafon Quality Control Process

✔ Material Inspection (Spectrometer testing)

✔ Dimensional Verification (CMM measurement)

✔ Performance Testing (3,000-cycle endurance tests)

✔ Final Audit (Pre-shipment quality review)

Why Global Buyers Choose Raydafon

✓ 20 Years Specialization in power transmission chains

✓ 75% Repeat Business Rate across 50+ countries

✓ Engineering Support from prototype to mass production

Take the Next Step - Contact Our Team

📞 Instant Quote: Receive pricing within 4 business hours

📦 Free Samples: Evaluate quality with no obligation

🛠 Technical Consultation: Our engineers are ready to assist

Email: [email protected]

Website: https://www.raydafonmachinery.com

Roller Chain