- Home

- About Us

- Products

- Chain

- Sprocket

- Pulley & Sheave

- Gearbox\Reducer

- Belt

- Coupling

- Gear Operator &Valve

- Gear\Rack

- Mechanical seal

- Hub & Bushing

- Hydraulic & Pheumatic

- Shaft Collar

- Locking Assembly

- PTO Shaft

- Mechanical parts

- Conveyor component

- universal joints

- Shaft & York

- vibrator, vibration motor

- Starter & Alternator

- Ungrouped

- Other

- Air Compressor

- News

- Download

- Send Inquiry

- Contact Us

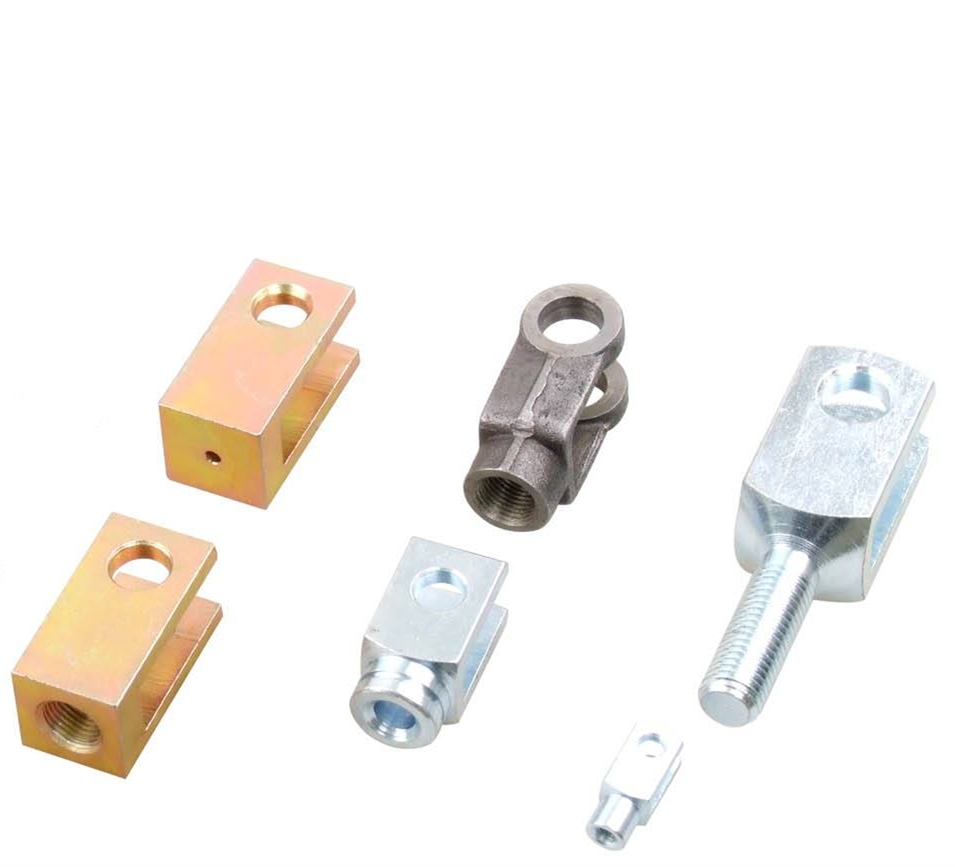

Shaft & York

Welcome to Shaft & York, your trusted partner in precision engineering and industrial solutions. With decades of experience in delivering high-quality products, we specialize in shafts, couplings, and mechanical components designed to meet the most demanding industrial applications. Below, we provide an in-depth look at our product specifications, supported by detailed tables and lists, ensuring you have all the information you need.

Product Specifications

Our premium shafts and couplings are engineered for durability and performance. Below are the key parameters for our most popular products:

Shaft Series

- Material: High-grade alloy steel (AISI 4140/4340)

- Diameter Range: 10mm – 500mm

- Surface Treatment: Hardened & ground, black oxide, or zinc plating

- Tolerance: IT6 – IT8

- Load Capacity: Up to 50,000 Nm

Coupling Series

| Model | Torque Capacity (Nm) | Max RPM | Bore Size (mm) |

|---|---|---|---|

| SY-Flex500 | 500 | 10,000 | 10-50 |

| SY-Rigid800 | 800 | 8,500 | 15-60 |

| SY-HighTorque1200 | 1,200 | 6,000 | 20-100 |

FAQ: Shaft & York Product Selection

Q: How do I choose the right shaft for my application?

A: Consider load capacity, rotational speed, and environmental conditions. Shaft & York offers custom solutions—contact our engineers for a tailored recommendation.

Q: What makes Shaft & York couplings stand out?

A: Our couplings feature precision machining, zero backlash, and high misalignment tolerance, ensuring smooth power transmission even in harsh conditions.

Additional Product Features

- Corrosion Resistance: Optional stainless steel or protective coatings.

- Customization: Tailored dimensions, keyways, and splines available.

- Certifications: ISO 9001, CE, and RoHS compliant.

Industry Applications

Shaft & York products are widely used in:

- Heavy machinery

- Automotive systems

- Renewable energy (wind turbines)

- Marine and aerospace

FAQ: Shaft & York Maintenance

Q: How often should I inspect my Shaft & York components?

A: Regular inspections every 3-6 months are recommended, depending on usage intensity. Check for wear, misalignment, or unusual vibrations.

Q: Can Shaft & York products be refurbished?

A: Yes, we offer reconditioning services for shafts and couplings to extend their lifespan while maintaining performance standards.

Technical Support

Our expert team provides:

- CAD models and technical drawings

- Installation guidance

- Failure analysis and troubleshooting

FAQ: Shaft & York Ordering Process

Q: What’s the lead time for custom Shaft & York components?

A: Standard lead times range from 2-4 weeks. Expedited options are available—discuss your timeline with our sales team.

Q: Do you offer global shipping?

A: Yes, Shaft & York ships worldwide with certified logistics partners to ensure timely and secure delivery.

Why Choose Shaft & York?

- Proven reliability in extreme conditions

- Competitive pricing without compromising quality

- Dedicated customer service from inquiry to after-sales

For inquiries or to request a quote, visit our contact page or reach out to our sales team. Trust Shaft & York for precision-engineered solutions that drive your operations forward.

Shaft & York