- Home

- About Us

- Products

- Chain

- Sprocket

- Pulley & Sheave

- Gearbox\Reducer

- Belt

- Coupling

- Gear Operator &Valve

- Gear\Rack

- Mechanical seal

- Hub & Bushing

- Hydraulic & Pheumatic

- Shaft Collar

- Locking Assembly

- PTO Shaft

- Mechanical parts

- Conveyor component

- universal joints

- Shaft & York

- vibrator, vibration motor

- Starter & Alternator

- Ungrouped

- Other

- Air Compressor

- News

- Download

- Send Inquiry

- Contact Us

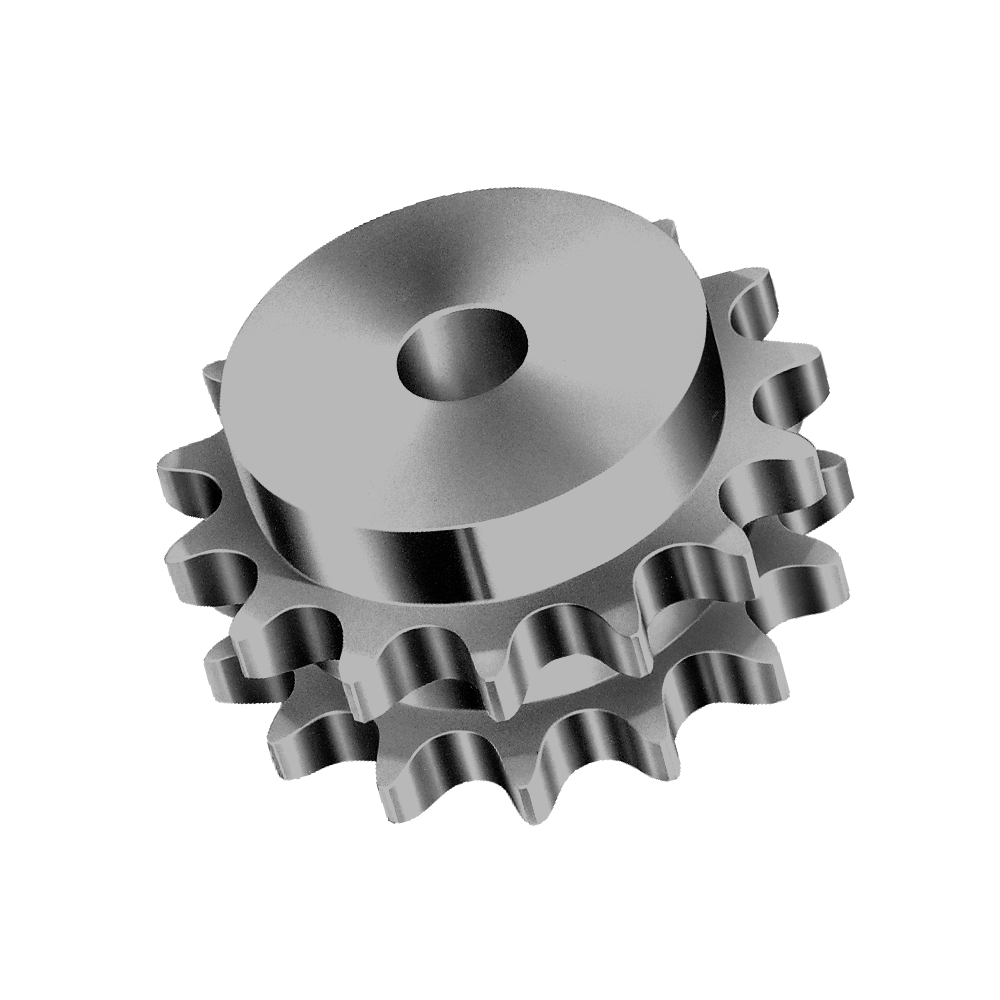

American Standard Sprockets

Premium American Standard Sprockets for Industrial Applications

American Standard Sprockets represent the gold standard in power transmission components, offering superior durability and precision engineering for demanding industrial applications. Our sprockets meet strict ANSI standards to ensure compatibility with all major chain types while delivering exceptional performance.

Key Product Features:

- Manufactured from high-grade alloy steel for maximum strength

- Precision machined teeth for smooth chain engagement

- Heat-treated surfaces for enhanced wear resistance

- Multiple bore options including taper lock, QD, and plain bore

- Available in single, double, and triple strand configurations

Technical Specifications

| Specification | Details |

|---|---|

| Material | Grade 1045 Carbon Steel |

| Hardness | 50-55 HRC (Rockwell C scale) |

| Tooth Finish | Ground and polished |

| ANSI Standards | B29.1 compliant |

| Temperature Range | -20°F to 300°F (-29°C to 149°C) |

American Standard Sprockets Size Chart

| Chain Size | Number of Teeth | Bore Options | Hub Configurations |

|---|---|---|---|

| ANSI 40 | 9-60 teeth | Plain, QD, Taper | A, B, C |

| ANSI 50 | 10-72 teeth | Plain, QD, Taper | A, B, C |

| ANSI 60 | 12-84 teeth | Plain, QD, Taper | A, B, C |

American Standard Sprockets FAQ

What makes American Standard Sprockets different from other brands?

American Standard Sprockets undergo rigorous quality control and are manufactured to exact ANSI specifications. Our proprietary heat treatment process extends sprocket life by up to 40% compared to standard sprockets. The precision-ground teeth ensure perfect chain engagement, reducing vibration and premature wear.

How do I determine the correct American Standard Sprockets size for my application?

You'll need to know your chain pitch (distance between pin centers), chain size designation (ANSI number), and required number of teeth. For speed ratio calculations, divide the number of teeth on the driven sprocket by the number on the drive sprocket. Our technical team can assist with complex application requirements.

What maintenance is required for American Standard Sprockets?

Regular inspection for wear patterns and proper lubrication are essential. Check for hook wear (curved tooth profile), which indicates replacement is needed. Proper chain tension and alignment significantly extend sprocket life. We recommend inspecting sprockets every 500 operating hours in normal conditions.

Specialized Sprocket Types Available

- Idler Sprockets for chain tension control

- Split Sprockets for easy installation without disassembling machinery

- Double Pitch Sprockets for conveyor applications

- Stainless Steel Sprockets for corrosive environments

- Plastic Sprockets for lightweight applications

Installation Guidelines

- Verify chain and sprocket compatibility before installation

- Check shaft diameter matches bore size precisely

- Use proper mounting tools - never hammer a sprocket onto a shaft

- Ensure perfect alignment between driver and driven sprockets

- Apply recommended torque values for set screws or locking devices

- Verify proper chain tension after installation

Performance Comparison: American Standard Sprockets vs. Generic Alternatives

| Feature | American Standard | Generic |

|---|---|---|

| Material Quality | Premium alloy steel | Standard carbon steel |

| Tooth Precision | Ground to 0.001" tolerance | Milled to 0.005" tolerance |

| Heat Treatment | Computer-controlled process | Basic hardening |

| Average Service Life | 10,000+ hours | 5,000-7,000 hours |

Common Applications for American Standard Sprockets

- Agricultural machinery (combines, balers, planters)

- Food processing equipment

- Packaging machinery

- Material handling systems

- Oil field equipment

- Mining machinery

- Construction equipment

American Standard Sprockets FAQ - Part 2

Can American Standard Sprockets be used with roller chains from different manufacturers?

Yes, American Standard Sprockets are designed to ANSI specifications, making them compatible with any ANSI-compliant roller chain. However, for optimal performance and longevity, we recommend using our matched sprocket and chain sets which are precision-engineered to work together.

What is the lead time for custom American Standard Sprockets?

Standard sprockets ship within 2-3 business days. Custom configurations (special materials, large sizes, or unique bore patterns) typically require 2-3 weeks for manufacturing. We offer expedited services for urgent requirements at additional cost.

How do I identify wear in American Standard Sprockets?

Measure across three pitches on the sprocket and compare to the same measurement on new chain. More than 3% elongation indicates replacement is needed. Visually inspect for hooked teeth, cracks, or excessive wear on the tooth profile. Worn sprockets will cause rapid chain wear.

Why Choose American Standard Sprockets

- Backed by 30+ years of manufacturing expertise

- Precision CNC machining for consistent quality

- Comprehensive product testing and certification

- Technical support from application engineers

- Nationwide distribution network

- Competitive pricing for premium quality

American Standard Sprockets FAQ - Part 3

What lubrication is recommended for American Standard Sprockets?

Use a high-quality chain lubricant specifically formulated for roller chains. In food processing applications, use USDA H1 approved lubricants. Avoid greases which can attract contaminants. Frequency depends on operating conditions - consult our lubrication guidelines chart for specific recommendations.

Are American Standard Sprockets suitable for high-speed applications?

Our precision-ground sprockets are excellent for high-speed applications up to 3,500 RPM when properly balanced. For extreme speed applications, we offer dynamically balanced sprockets with reduced mass and special tooth profiles to minimize vibration and noise.

Do American Standard Sprockets come with any warranty?

All American Standard Sprockets come with a 1-year warranty against manufacturing defects when used under normal operating conditions. Special applications may qualify for extended warranties - consult with our technical team for details.

Ordering Information

To order American Standard Sprockets, you'll need the following specifications:

- Chain size (ANSI number)

- Number of teeth

- Bore type and dimensions

- Hub configuration (if applicable)

- Special requirements (material, coating, etc.)

American Standard Sprockets