- Home

- About Us

- Products

- Chain

- Sprocket

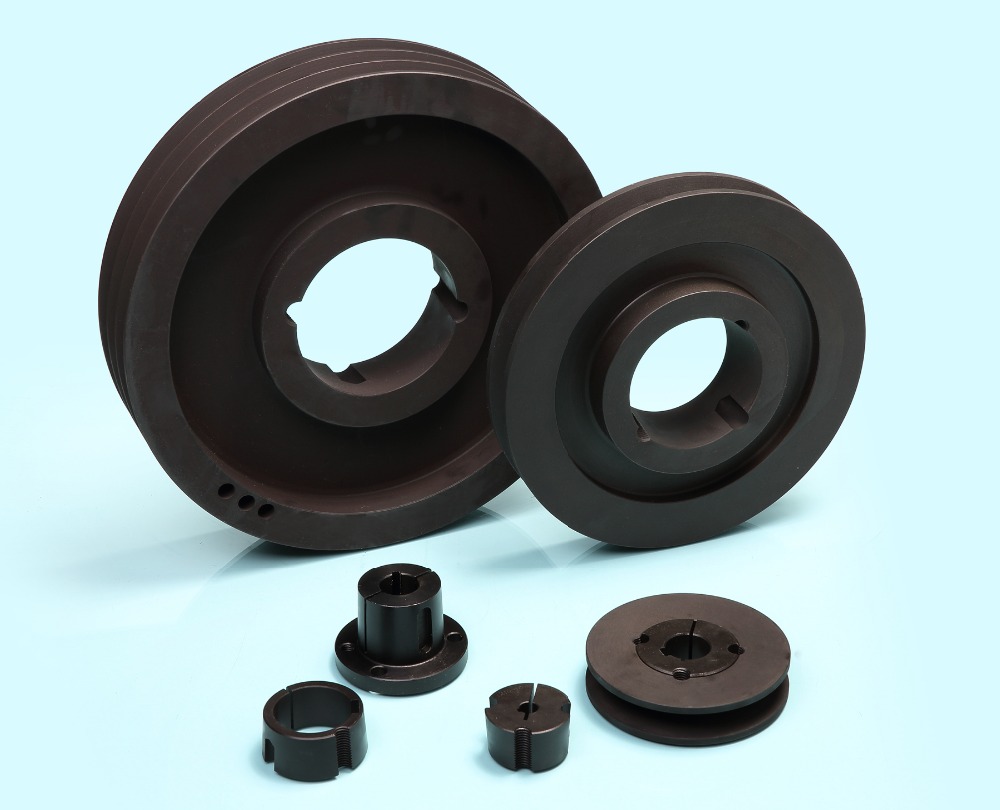

- Pulley & Sheave

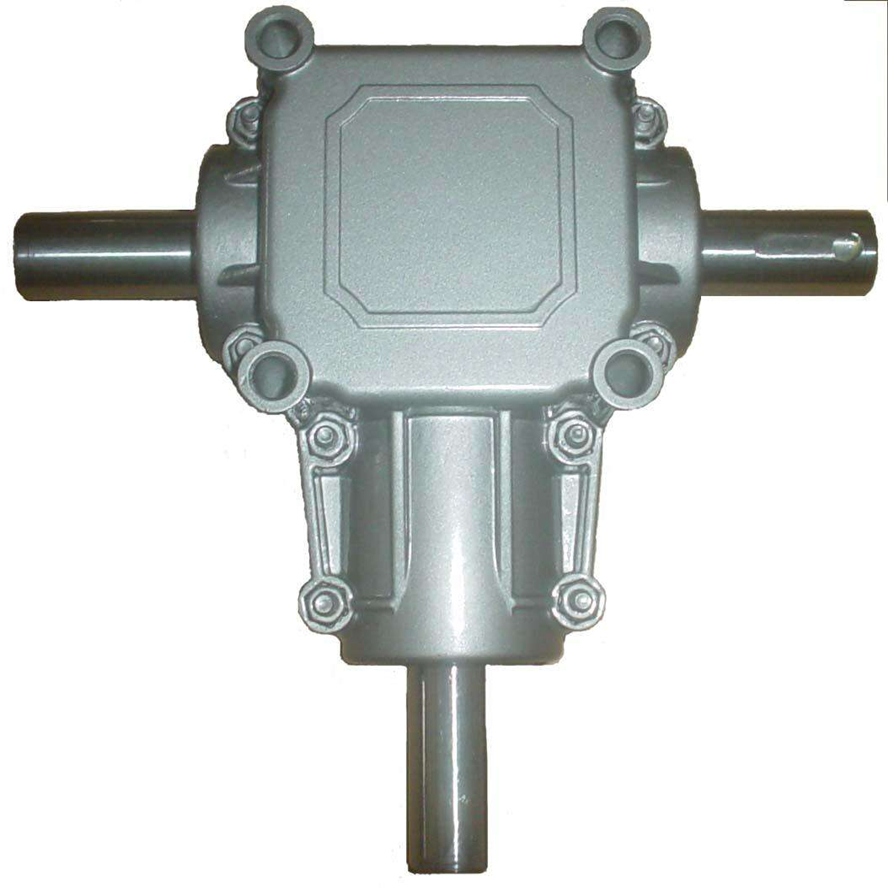

- Gearbox\Reducer

- Belt

- Coupling

- Gear Operator &Valve

- Gear\Rack

- Mechanical seal

- Hub & Bushing

- Hydraulic & Pheumatic

- Shaft Collar

- Locking Assembly

- PTO Shaft

- Mechanical parts

- Conveyor component

- universal joints

- Shaft & York

- vibrator, vibration motor

- Starter & Alternator

- Ungrouped

- Other

- Air Compressor

- News

- Download

- Send Inquiry

- Contact Us

vibrator, vibration motor

Vibrator and vibration motor technology has become essential in various industries, from consumer electronics to industrial applications. Our high-quality vibrators and vibration motors are designed to deliver reliable performance with precise control. Below is a detailed breakdown of our product specifications.

Product Specifications

Key Features

- High torque and low noise operation

- Precision-engineered for consistent vibration output

- Durable construction with long lifespan

- Wide voltage range compatibility

- Customizable vibration patterns

Technical Parameters

| Model | Voltage (V) | Speed (RPM) | Current (mA) | Vibration Force (G) |

|---|---|---|---|---|

| VM-1020 | 3-6 | 12,000 | 80 | 1.2 |

| VM-2030 | 5-12 | 15,000 | 120 | 2.0 |

| VM-3050 | 12-24 | 18,000 | 200 | 3.5 |

Applications

Our vibrator and vibration motor products are widely used in:

- Mobile devices and wearables

- Industrial equipment

- Medical devices

- Automotive systems

- Gaming controllers

FAQ: Vibrator and Vibration Motor Common Questions

1. What factors should I consider when selecting a vibration motor?

When choosing a vibrator or vibration motor, consider the required vibration force, operating voltage, current consumption, size constraints, and environmental conditions. Our technical team can help you select the optimal model based on your application requirements.

2. How long is the typical lifespan of these vibration motors?

Our high-quality vibrators and vibration motors are designed for extended operation, with typical lifespans ranging from 10,000 to 50,000 hours depending on the model and operating conditions. The VM-3050 series features enhanced bearings and construction for the longest operational life.

3. Can these vibration motors be customized for specific applications?

Yes, we offer extensive customization options for our vibrator and vibration motor products. This includes modified vibration patterns, different shaft configurations, specialized mounting options, and tailored electrical characteristics. Contact our engineering team with your specific requirements.

Installation and Maintenance

Proper installation ensures optimal performance of your vibrator or vibration motor:

- Ensure secure mounting to prevent excessive vibration transfer

- Maintain proper alignment for shaft-based models

- Use appropriate power supplies within specified voltage ranges

- Regularly inspect for wear and maintain clean operating environments

Quality Assurance

All our vibrator and vibration motor products undergo rigorous testing including:

- Vibration consistency verification

- Durability testing under various conditions

- Electrical performance validation

- Environmental stress testing

For more detailed technical information about our vibrator and vibration motor products, please contact our sales team who can provide datasheets, application notes, and engineering support.

vibrator, vibration motor