- Home

- About Us

- Products

- Chain

- Sprocket

- Pulley & Sheave

- Gearbox\Reducer

- Belt

- Coupling

- Gear Operator &Valve

- Gear\Rack

- Mechanical seal

- Hub & Bushing

- Hydraulic & Pheumatic

- Shaft Collar

- Locking Assembly

- PTO Shaft

- Mechanical parts

- Conveyor component

- universal joints

- Shaft & York

- vibrator, vibration motor

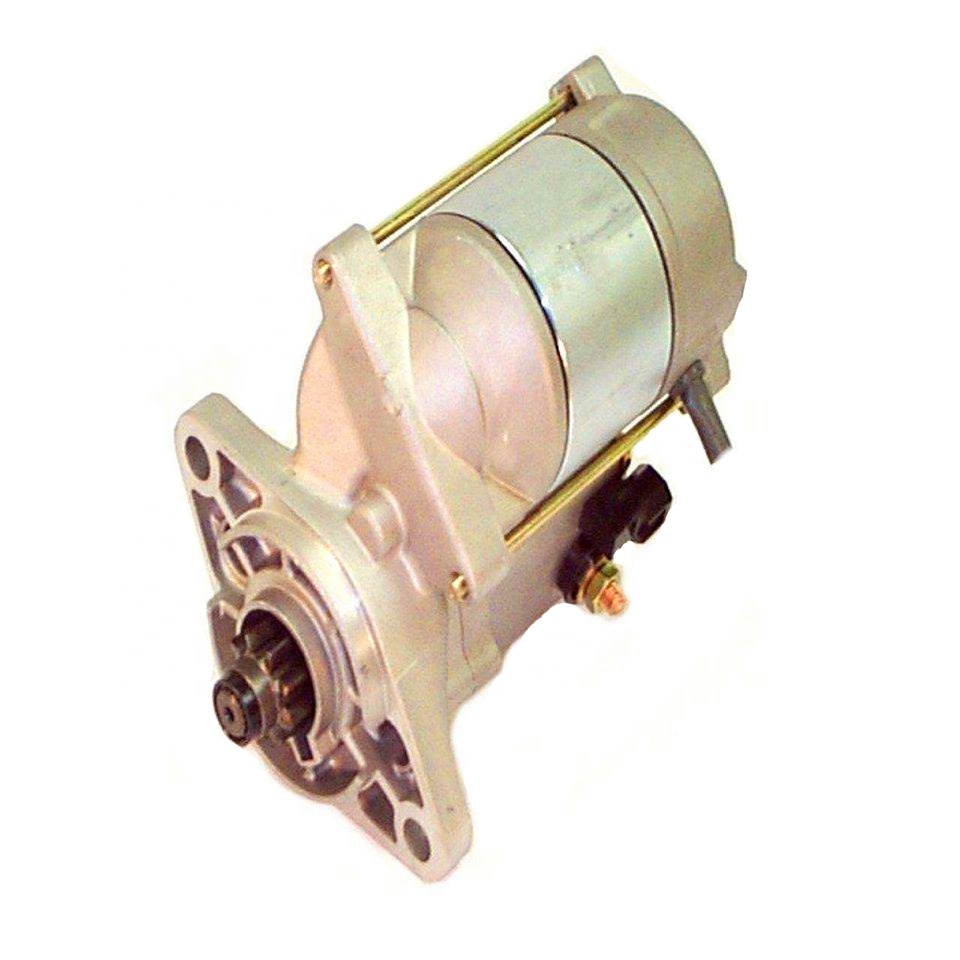

- Starter & Alternator

- Ungrouped

- Other

- Air Compressor

- News

- Download

- Send Inquiry

- Contact Us

Gear\Rack

Gear Rack: The Ultimate Solution for Precision Motion Control

Gear racks are essential components in various industries, providing linear motion through engagement with pinion gears. Our high-quality Gear Rack products deliver exceptional performance, durability, and precision for all your industrial applications.

Key Features of Our Gear Racks

- Manufactured from premium-grade materials for extended service life

- Precision-cut teeth for smooth operation and minimal backlash

- Available in various module sizes and lengths to suit diverse applications

- Heat-treated options available for enhanced strength and wear resistance

- Custom configurations possible to meet specific project requirements

Product Specifications

| Model | Module | Material | Standard Length | Load Capacity |

|---|---|---|---|---|

| GR-M1 | 1.0 | C45 Steel | 1000mm | 500N |

| GR-M1.5 | 1.5 | 4140 Steel | 1500mm | 800N |

| GR-M2 | 2.0 | Stainless Steel | 2000mm | 1200N |

| GR-M3 | 3.0 | Case Hardened Steel | 2500mm | 2000N |

Gear Rack FAQ Section

What are the main applications of Gear Racks?

Gear Racks are widely used in CNC machinery, automation systems, robotics, linear actuators, and various industrial equipment requiring precise linear motion. They are particularly valuable in applications where long travel distances are needed with high positioning accuracy.

How do I choose the right Gear Rack for my application?

Consider these key factors: 1) Required load capacity, 2) Operational speed, 3) Accuracy requirements, 4) Environmental conditions (temperature, exposure to chemicals), 5) Space constraints, and 6) Compatibility with existing pinion gears. Our technical team can assist in selecting the optimal Gear Rack configuration for your specific needs.

Additional Product Details

Our Gear Racks undergo rigorous quality control measures, including dimensional inspections, hardness testing, and surface finish evaluations. We offer various mounting options, including standard straight racks and custom curved configurations for specialized applications.

What maintenance do Gear Racks require?

Proper maintenance includes regular lubrication with appropriate gear oil or grease, periodic cleaning to remove debris, inspection for wear patterns, and timely replacement when tooth wear exceeds recommended limits. Maintenance frequency depends on operating conditions but typically ranges from monthly to quarterly inspections for continuous operation systems.

Technical Advantages

- Precision ground tooth profile for smooth operation

- Multiple mounting hole patterns available

- Corrosion-resistant options for harsh environments

- Backlash adjustment capabilities

- Compatible with standard pinion gears

Performance Data

| Parameter | Standard Grade | Precision Grade | High-Performance Grade |

|---|---|---|---|

| Positioning Accuracy | ±0.1mm/m | ±0.05mm/m | ±0.02mm/m |

| Maximum Speed | 2 m/s | 3 m/s | 5 m/s |

| Service Life | 5,000 km | 7,500 km | 10,000+ km |

For specialized requirements, we offer custom Gear Rack solutions including different pressure angles, helical teeth configurations, and material combinations. Contact our engineering team to discuss your project specifications.

Gear\Rack