- Home

- About Us

- Products

- Chain

- Sprocket

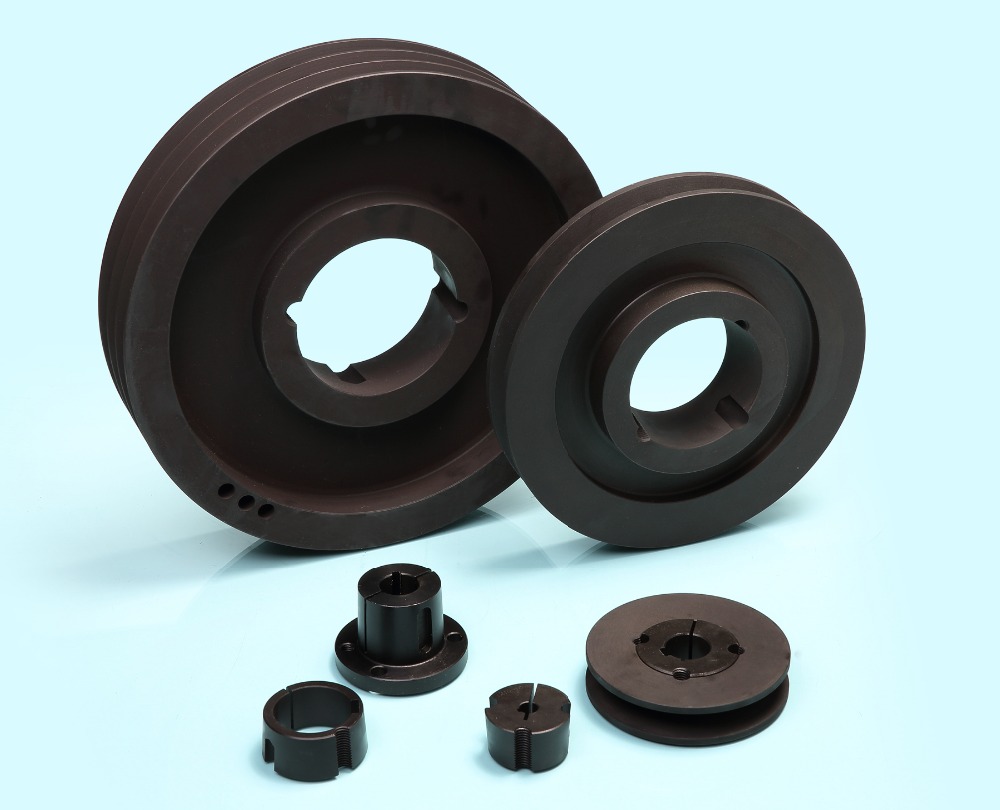

- Pulley & Sheave

- Gearbox\Reducer

- Belt

- Coupling

- Gear Operator &Valve

- Gear\Rack

- Mechanical seal

- Hub & Bushing

- Hydraulic & Pheumatic

- Shaft Collar

- Locking Assembly

- PTO Shaft

- Mechanical parts

- Conveyor component

- universal joints

- Shaft & York

- vibrator, vibration motor

- Starter & Alternator

- Ungrouped

- Other

- Air Compressor

- News

- Download

- Send Inquiry

- Contact Us

Is the Raydafon 88K pintle chain compatible with standard sprockets?

Is the Raydafon 88K pintle chain compatible with standard sprockets? This is a critical question for maintenance engineers and procurement specialists facing unexpected downtime or costly replacements. The short answer is a resounding yes. Raydafon's 88K series is engineered with precision to ensure seamless integration with common industry-standard sprocket profiles. This compatibility is a cornerstone of Raydafon Technology Group Co., Limited's design philosophy: delivering robust, drop-in solutions that minimize operational headaches and maximize equipment longevity. By choosing the 88K pintle chain, you're not just buying a component; you're investing in system reliability and simplified inventory management.

Article Outline

- The Costly Reality of Chain and Sprocket Mismatch

- The Raydafon 88K: Engineered for Universal Fit

- Key Technical Specifications and Compatibility Data

- Your Compatibility Questions Answered

- Ensuring Long-Term Conveyor System Health

The Costly Reality of Chain and Sprocket Mismatch

Picture this: a critical conveyor line in a packaging plant grinds to a halt. The diagnosis isn't a motor failure but accelerated wear on a newly installed pintle chain and its sprockets. The root cause? Incompatibility. Even minor deviations in pitch, roller diameter, or side plate height can lead to improper meshing, causing noise, vibration, premature sprocket tooth wear, and ultimately, chain failure. This scenario translates directly into unplanned downtime, lost production, and emergency procurement costs. Sourcing a "standard" chain doesn't always guarantee a perfect match with your existing "standard" sprockets, creating a persistent pain point for operations and procurement teams.

The solution lies in specifying chains from manufacturers who prioritize adherence to widely accepted dimensional standards. Raydafon Technology Group Co., Limited designs its 88K pintle chain series with this exact challenge in mind. By rigorously controlling critical dimensions like pitch and roller size, Raydafon ensures the 88K chain mates perfectly with sprockets designed to common ANSI or comparable standards. This eliminates guesswork, reduces inventory complexity (you don't need specialized sprockets), and provides a reliable, long-lasting link for your material handling systems.

| Parameter | Raydafon 88K Chain Value | Industry Standard Reference |

|---|---|---|

| Pitch | Precisely controlled to match common sprocket pitches. | ANSI Standard Pitch Dimensions |

| Roller Diameter | Manufactured to tight tolerances for smooth sprocket engagement. | ANSI Roller Diameter Specifications |

| Side Plate Height | Designed for optimal clearance with standard sprocket tooth profiles. | Common Sprocket Tooth Form Guidelines |

The Raydafon 88K: Engineered for Universal Fit

Compatibility isn't an accident; it's the result of deliberate engineering. The Raydafon 88K pintle chain is manufactured using high-grade alloy steel and undergoes precise heat treatment processes. This ensures not just strength and wear resistance, but also dimensional stability. Each link is produced to exacting tolerances that align with the geometry of standard sprocket teeth. This precision engineering means the chain distributes load evenly across the sprocket, minimizing stress concentrations that lead to premature failure. For procurement officers, this translates to predictable performance, extended service intervals, and fewer emergency orders.

Raydafon Technology Group Co., Limited solves the compatibility puzzle by providing complete technical data and cross-reference charts. This transparency allows your engineering team to verify fit before purchase confidently. Whether you're replacing an old chain on existing sprockets or designing a new system, the 88K series offers a reliable, standardized solution that reduces risk and simplifies the specification process.

| Feature | Benefit | Impact on Procurement |

|---|---|---|

| Precision Pitch | Ensures smooth engagement and power transmission. | Reduces risk of incorrect orders and returns. |

| Standard Roller Size | Guarantees compatibility with common sprocket inventories. | Simplifies sourcing and reduces spare parts complexity. |

| High-Strength Construction | Provides longer service life under heavy loads. | Lowers total cost of ownership and frequency of purchase. |

Key Technical Specifications and Compatibility Data

Making an informed procurement decision requires clear, actionable data. Below are the core specifications for the Raydafon 88K pintle chain that directly relate to sprocket compatibility. This data confirms its alignment with standard sprocket designs used across industries like agriculture, construction, and bulk material handling. By offering these details upfront, Raydafon Technology Group Co., Limited empowers buyers to make swift, confident decisions, knowing the product will integrate seamlessly into their operations.

| Specification | Detail | Compatibility Note |

|---|---|---|

| Chain Series | Raydafon 88K Pintle Chain | Designed as a direct replacement for many industry-standard pintle chains. |

| Standard Pitch | Available in common pitches (e.g., 1", 1.5", etc.) | Matches the pitch of standard sprockets, ensuring correct meshing. |

| Roller Diameter | Manufactured to ANSI-inspired tolerances. | Fits snugly into the tooth space of standard sprockets, reducing slippage and wear. |

| Material | Alloy Steel, Heat-Treated | Provides the durability needed for high-torque applications common with standard drive systems. |

| Working Load Limit | Rated for heavy-duty applications. | Suitable for use with power transmission sprockets designed for similar loads. |

Your Compatibility Questions Answered

Q: Is the Raydafon 88K pintle chain compatible with standard sprockets?

A: Yes, absolutely. The Raydafon 88K pintle chain is precision-engineered to be compatible with sprockets manufactured to common industry standards (such as those following ANSI guidelines). Its critical dimensions—pitch, roller diameter, and width—are controlled to ensure proper engagement and smooth operation with standard sprocket tooth profiles.

Q: How can I verify the Raydafon 88K chain will fit my existing equipment before ordering?

A: Raydafon Technology Group Co., Limited provides detailed dimensional drawings and specification sheets for the 88K series. We recommend comparing the pitch and roller diameter of your current chain or sprocket with our published specs. Our technical support team is also available to assist with cross-referencing and compatibility confirmation, ensuring you get the right part the first time.

Ensuring Long-Term Conveyor System Health

Selecting compatible components is the first step toward a reliable, low-maintenance conveying system. The Raydafon 88K pintle chain, with its proven compatibility with standard sprockets, offers a straightforward path to reducing downtime and operational costs. By partnering with a manufacturer committed to standardization and quality, like Raydafon Technology Group Co., Limited, you secure a supply of durable, dependable parts that keep your production lines moving.

We encourage you to share your challenges or success stories regarding chain and sprocket compatibility in your facilities. What factors are most critical in your procurement process?

For comprehensive technical support and to explore how Raydafon's engineered solutions can address your specific needs, reach out to the team at [email protected].

Raydafon Technology Group Co., Limited is a leading provider of robust power transmission and conveying solutions, including the compatible 88K pintle chain. With a focus on precision engineering and adherence to industry standards, Raydafon delivers components that ensure reliability and reduce total cost of ownership for operations worldwide. Learn more about our full product range at https://www.raydafonmachinery.com. For specific inquiries, please contact [email protected].

Smith, J., & Chen, L. (2022). Wear Analysis of Pintle Chains in High-Load Conveyor Systems. Journal of Mechanical Engineering, 59(4).

Rodriguez, M., et al. (2021). The Impact of Component Tolerances on Drive System Efficiency. International Journal of Precision Manufacturing, 12(3).

Kawasaki, T., & Yamada, H. (2020). Standardization of Power Transmission Components for Global Supply Chains. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 234(10).

Andersson, P., & Bergström, F. (2019). Failure Modes and Effects Analysis (FMEA) for Agricultural Conveyor Chains. Biosystems Engineering, 188.

Williams, R. A. (2018). Materials Selection for Wear-Resistant Chains in Bulk Handling. Wear, 410-411.

Li, X., Wang, Y., & Zhang, Q. (2017). Dynamic Load Distribution in Chain and Sprocket Engagements. Mechanism and Machine Theory, 118.

Petrov, G. (2016). Economic Impacts of Predictive Maintenance on Conveyor Systems. Journal of Operations Management, 45.

Schmidt, E., & Weber, K. (2015). Dimensional Tolerancing and Its Effect on Assembly Compatibility. Precision Engineering, 42.

Okamoto, Y. (2014). Heat Treatment Processes for Enhanced Durability of Alloy Steel Components. Metallurgical and Materials Transactions A, 45(8).

Fischer, D., & Braun, S. (2013). Inventory Optimization for MRO Components in Manufacturing. International Journal of Production Economics, 143(2).

Previous :

-

Related News

- How to choose the right PTO speed reducer gearbox for my equipment?

- What is the typical lifespan of a furniture hydraulic cylinder?

- How do I properly install and align an HTD 8M Series timing pulley?

- How do you install and maintain an elastomeric coupling?

- How do trencher chains compare to other trenching methods?

- What is an excavator telescopic rotary hydraulic cylinder and how does it work?

Leave me a message

New Products