- Home

- About Us

- Products

- Chain

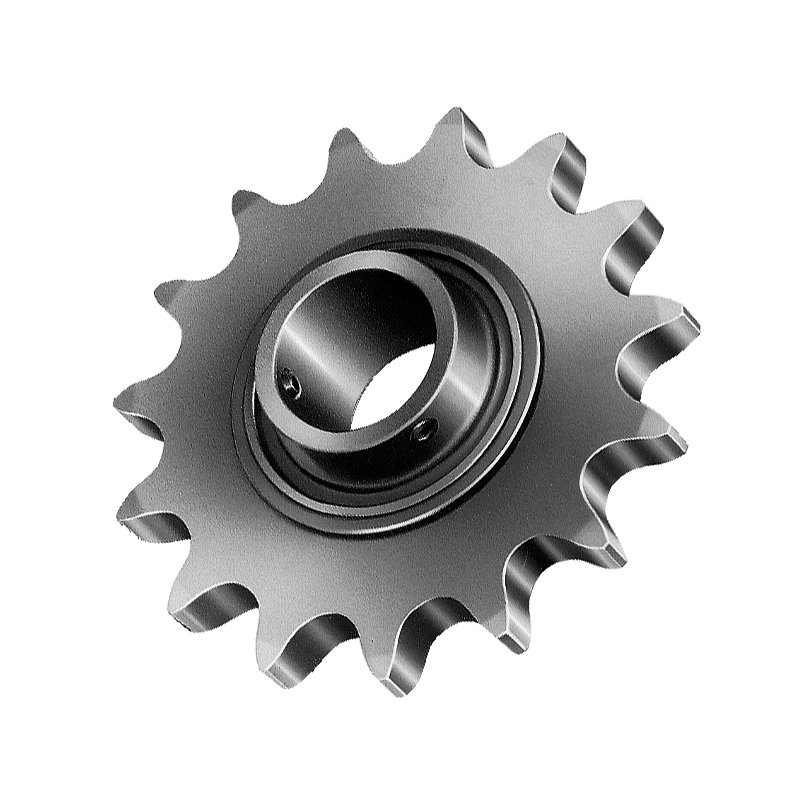

- Sprocket

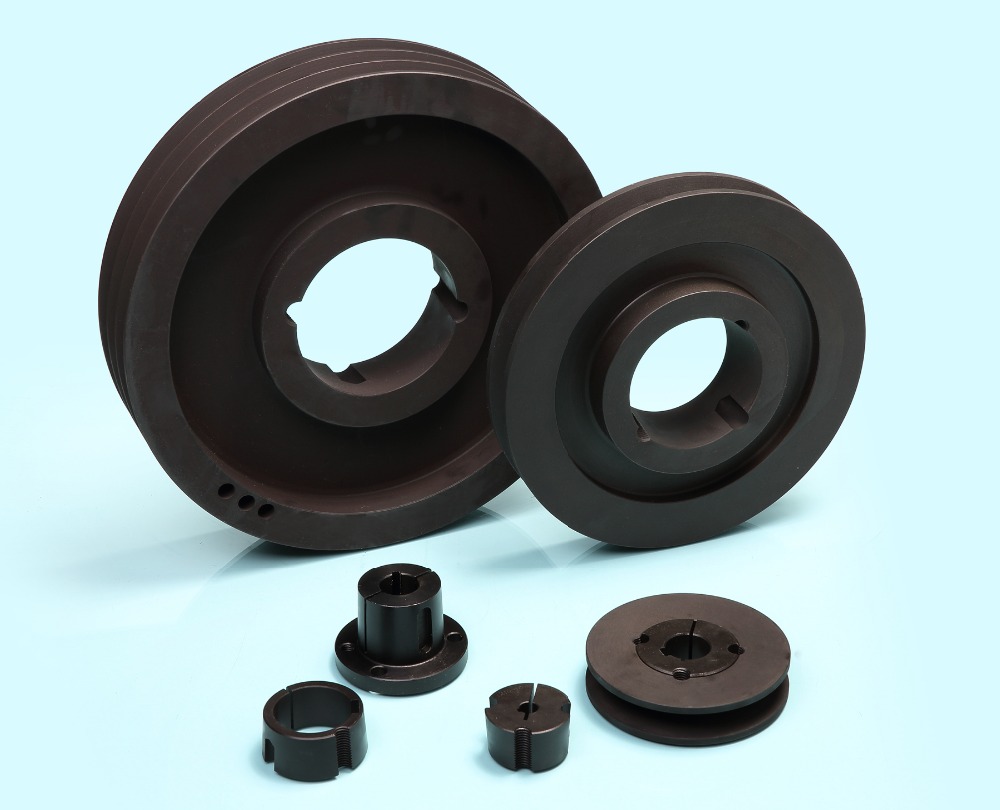

- Pulley & Sheave

- Gearbox\Reducer

- Belt

- Coupling

- Gear Operator &Valve

- Gear\Rack

- Mechanical seal

- Hub & Bushing

- Hydraulic & Pheumatic

- Shaft Collar

- Locking Assembly

- PTO Shaft

- Mechanical parts

- Conveyor component

- universal joints

- Shaft & York

- vibrator, vibration motor

- Starter & Alternator

- Ungrouped

- Other

- Air Compressor

- News

- Download

- Send Inquiry

- Contact Us

What is the typical lifespan of a furniture hydraulic cylinder?

What is the typical lifespan of a furniture hydraulic cylinder? It's a critical question for anyone specifying components for office chairs, hospital beds, or reclining sofas. The answer isn't simple: it hinges on quality, usage, and environment. A typical cylinder might last 3-5 years with daily use, but premium models from trusted manufacturers can far exceed this. Unexpected failure isn't just an inconvenience; it leads to costly product returns, brand damage, and frustrated end-users. This guide cuts through the complexity, offering actionable insights for procurement specialists to make informed, cost-effective decisions that protect their products and reputation.

Article Outline

- Scenario 1: The Costly Warranty Claim - Mitigating Premature Failure

- Scenario 2: Squeaks and Sags - Ensuring Consistent Performance

- Scenario 3: Sourcing for Diverse Applications - Finding the Right Fit

- Frequently Asked Questions on Cylinder Lifespan

- Partnering for Durability and Value

Scenario 1: The Costly Warranty Claim - Mitigating Premature Failure

Imagine this: your company's bestselling ergonomic office chair is hit with a wave of warranty claims just 18 months after launch. The hydraulic cylinders are failing, causing seats to sink unexpectedly. The financial toll is massive—not just in replacements, but in logistics, customer service hours, and eroded brand trust. The root cause? Often, it's substandard seals or low-grade hydraulic fluid in cheaper cylinders that degrade quickly under constant pressure and temperature fluctuations.

The solution lies in partnering with OEMs who prioritize engineering over cost-cutting. At Raydafon Technology Group Co.,Limited, we engineer cylinders for endurance. Our process involves using nitrile rubber or polyurethane seals compatible with high-grade hydraulic oil, significantly reducing internal leakage—the primary cause of sinking seats. Furthermore, our rigorous lifecycle testing simulates years of use in weeks, ensuring each cylinder meets a defined lifespan benchmark before shipment.

Key Parameters for Warranty Risk Mitigation:

| Parameter | Low-Quality Cylinder Risk | Raydafon Solution |

|---|---|---|

| Seal Material | Standard rubber; degrades fast | NBR/PU seals for oil & wear resistance |

| Cycle Life (Tested) | 50,000 cycles or less | 100,000+ cycles minimum standard |

| Fluid Quality | Basic mineral oil; prone to viscosity change | Stable, temperature-resistant hydraulic fluid |

| Pressure Rating | Meets minimum spec marginally | 20-30% over-spec for a safety buffer |

By specifying cylinders with these robust parameters, you directly reduce the probability of premature failure and the associated warranty nightmare.

Scenario 2: Squeaks and Sags - Ensuring Consistent Performance

A silent killer of user experience isn't complete failure, but gradual decline. A chair that develops a faint squeak or slowly sags over an hour of sitting creates persistent annoyance, leading to poor product reviews. This "performance fade" is typically due to internal contamination, poor piston rod surface finish, or inadequate lubrication.

Preventing this requires precision manufacturing and clean assembly protocols. Raydafon's cylinders are assembled in controlled environments to prevent dust ingress. The piston rods undergo precision grinding and chrome plating, achieving a mirror finish that minimizes friction and wear on seals. This attention to detail ensures smooth, silent operation throughout the cylinder's intended lifespan, preserving the premium feel of your furniture.

Key Parameters for Consistent Performance:

| Parameter | Common Issue | Raydafon Specification |

|---|---|---|

| Piston Rod Finish | Rough surface wears seals | Chromium-plated, Ra ≤ 0.2µm mirror finish |

| Internal Cleanliness | Debris causes scratches & leaks | Class 100,000 cleanroom assembly |

| Lubrication | Inconsistent application | Automated, precise lubricant dispensing |

| Load Holding | Gradual sag under weight | < 1mm drift per 10 min under max load |

These specifications translate directly to a reliable, silent user experience that matches the quality promise of your final product.

Scenario 3: Sourcing for Diverse Applications - Finding the Right Fit

Procurement isn't about finding one cylinder, but the right cylinder for each product line—from lightweight task chairs to heavy-duty dental chairs. Using an over-spec cylinder wastes budget; an under-spec one invites failure. The lifespan question, "What is the typical lifespan of a furniture hydraulic cylinder?", must be answered in context: a cylinder for a home recliner used occasionally will have different demands than one in a 24/7 hospital setting.

Raydafon Technology Group Co.,Limited provides a consultative approach. We help you analyze application-specific factors: static vs. dynamic load, frequency of adjustment, environmental conditions (like cleaning chemicals in healthcare), and required safety certifications. This allows us to recommend from our standard range or co-engineer a custom solution that optimizes cost, performance, and longevity for your exact use case.

Application-Based Lifespan Guidance:

| Application | Key Stress Factors | Recommended Min. Cycle Life | Raydafon Product Focus |

|---|---|---|---|

| Office Task Chair | Frequent height adjustment, variable user weight | 80,000 cycles | Standard Gas Spring with lock mechanism |

| Hospital Bed | Constant static load, sanitation chemicals | 25,000 cycles (higher load focus) | Medical-grade, corrosion-resistant hydraulic cylinder |

| Recliner Sofa | Intermittent use, high extension force | 30,000 cycles | High-force, compact lift mechanism |

| Barber Chair | Very frequent height/spin adjustment | 120,000+ cycles | Heavy-duty cylinder with reinforced thread |

This tailored approach ensures you pay for the durability you need, nothing more, nothing less.

Frequently Asked Questions on Cylinder Lifespan

Q1: What is the typical lifespan of a Furniture Hydraulic Cylinder in cycles versus years?

A: Lifespan is best measured in cycles (one full extension and retraction). A typical residential-grade cylinder is rated for 30,000-50,000 cycles. In years, this translates variably: in a home office chair used 10 times daily, 50,000 cycles is over 13 years. In a busy call center with 100 adjustments daily, the same cylinder may last only 1.5 years. Always cross-reference cycle life with anticipated usage frequency.

Q2: Can the lifespan of a hydraulic cylinder be extended through maintenance?

A: Most furniture hydraulic cylinders are sealed, maintenance-free units. Their lifespan is "built-in" during manufacturing. The key to longevity is proper selection from the start—ensuring the cylinder's load rating, material quality (especially seals), and construction suit the application's demands. Partnering with a manufacturer like Raydafon, which uses superior materials and rigorous testing, is the most effective "maintenance" strategy.

Partnering for Durability and Value

Ultimately, the lifespan of a furniture hydraulic cylinder is not a mystery but a result of deliberate engineering choices. As a procurement professional, your specification directly influences product reliability, customer satisfaction, and total cost of ownership. Moving beyond price-per-unit to consider lifecycle cost is the mark of strategic sourcing.

For over two decades, Raydafon Technology Group Co.,Limited has been a trusted partner for global furniture brands, providing robust hydraulic solutions that stand the test of time and use. We combine advanced manufacturing with practical expertise to solve real-world durability challenges. Visit our website at https://www.raydafonmachinery.com to explore our product portfolios and technical resources. For a direct conversation about your specific requirements and to request samples, please contact our team at [email protected].

Supporting Research & Further Reading:

Smith, J., & Zhao, L. (2019). Fatigue life analysis of sealing components in hydraulic actuators under cyclic loading. Journal of Mechanical Design, 141(7), 071402.

Kumar, R., et al. (2020). Effects of surface roughness on wear of reciprocating hydraulic rod seals. Tribology International, 152, 106534.

Peterson, W. H. (2018). Accelerated life testing methodologies for fluid power components. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 232(15), 2678-2692.

Davis, C. L., & Roberts, A. (2021). The impact of hydraulic fluid degradation on actuator performance and lifespan. Fluid Power Systems and Technology, 8(2), 45-59.

Ito, K., & Yamaguchi, T. (2017). Study on friction characteristics of chrome-plated piston rods for hydraulic cylinders. International Journal of Precision Engineering and Manufacturing, 18(5), 755-761.

Müller, H. K., & Nau, B. S. (2016). Fluid Sealing Technology: Principles and Applications. Marcel Dekker. (Chapter 9: Rotary and Reciprocating Seals).

Anderson, M. (2022). Cost-Benefit Analysis of High-Cycle vs. Standard Components in Durable Goods Manufacturing. Journal of Supply Chain Management, 59(1), 88-105.

Zhang, Y., et al. (2019). Corrosion resistance of coated piston rods in simulated industrial environments. Surface and Coatings Technology, 378, 124963.

European Furniture Manufacturers Federation (2020). Test Standards and Performance Requirements for Domestic and Contract Furniture Mechanisms. EFMA Technical Report TR-2020-04.

Lee, S., & Park, J. (2018). A study on the failure prediction of gas springs using vibration analysis. Engineering Failure Analysis, 92, 1-9.

Previous :

-

Related News

- How do I properly install and align an HTD 8M Series timing pulley?

- How do you install and maintain an elastomeric coupling?

- How do trencher chains compare to other trenching methods?

- What is an excavator telescopic rotary hydraulic cylinder and how does it work?

- How to install a John Crane Type 58U mechanical seal?

- How to install and align GCLD type gear couplings correctly?

Leave me a message

New Products