Powder Metallurgy: The Advanced Manufacturing Solution

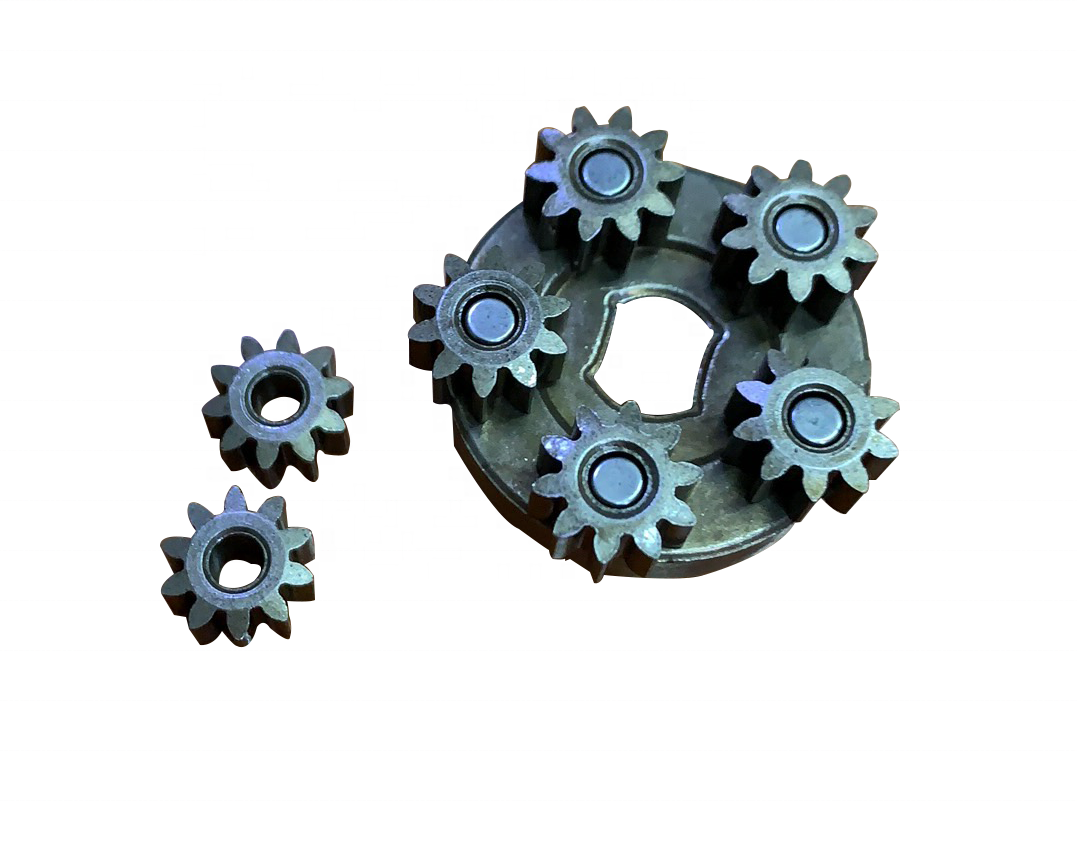

Powder Metallurgy is a highly efficient metal forming process that produces precision components with exceptional mechanical properties. This manufacturing technique offers significant advantages over traditional methods, including material savings, cost efficiency, and the ability to create complex geometries.

Key Advantages of Powder Metallurgy

- High material utilization (up to 97%)

- Excellent dimensional accuracy (±0.05 mm)

- Superior surface finish (Ra 1.6-3.2 μm)

- Ability to combine multiple materials

- Mass production capability with consistent quality

Powder Metallurgy Product Specifications

| Parameter | Specification | Standard |

|---|---|---|

| Material Density | 6.8-7.4 g/cm³ | ISO 2738 |

| Tensile Strength | 500-850 MPa | ASTM B925 |

| Hardness | 60-85 HRB | ISO 6508 |

| Dimensional Tolerance | ±0.1% or ±0.05 mm | MPIF 35 |

| Surface Roughness | 1.6-3.2 μm Ra | ISO 4287 |

Powder Metallurgy Applications

Our Powder Metallurgy components are widely used in:

- Automotive industry (gears, bearings, sprockets)

- Aerospace components (structural parts, fasteners)

- Industrial machinery (pumps, valves, actuators)

- Medical devices (surgical instruments, implants)

- Consumer electronics (heat sinks, connectors)

Powder Metallurgy FAQ Section 1

Q: What materials can be processed with Powder Metallurgy?

A: Powder Metallurgy can process various materials including iron, steel, stainless steel, copper, aluminum, titanium, and specialty alloys. The process is particularly effective for materials that are difficult to machine or require special properties. We can also create custom material combinations to meet specific application requirements.

Q: How does Powder Metallurgy compare to traditional machining?

A: Powder Metallurgy offers several advantages over machining: it produces less material waste (typically 3% vs 40-60% with machining), allows for more complex shapes, provides better material utilization, and often results in better mechanical properties due to controlled porosity. The process is also more cost-effective for medium to high volume production.

Custom Powder Metallurgy Solutions

We offer customized Powder Metallurgy services to meet your specific requirements:

| Service | Capability | Lead Time |

|---|---|---|

| Prototyping | 1-100 pieces | 2-3 weeks |

| Small Batch Production | 100-10,000 pieces | 3-5 weeks |

| Mass Production | 10,000+ pieces | 6-8 weeks |

| Secondary Operations | Heat treatment, plating, machining | 1-2 weeks extra |

Powder Metallurgy FAQ Section 2

Q: What are the limitations of Powder Metallurgy?

A: While Powder Metallurgy is versatile, it does have some limitations: part size is constrained by press capacity (typically up to 100mm in height, 200mm in diameter), very thin walls (below 1mm) can be challenging, and certain undercuts may require secondary operations. However, many of these limitations can be addressed through innovative design solutions.

Q: How strong are Powder Metallurgy parts compared to wrought materials?

A: Modern Powder Metallurgy techniques can produce parts with mechanical properties approaching those of wrought materials. Through optimized compaction, sintering, and optional secondary operations like heat treatment, we can achieve tensile strengths up to 1200 MPa for certain alloys. The controlled porosity can also be beneficial for applications requiring oil retention or damping characteristics.

Quality Assurance in Powder Metallurgy

Our Powder Metallurgy manufacturing process includes rigorous quality control measures:

- 100% dimensional inspection of first articles

- Statistical process control during production

- Material certification for all raw powders

- Mechanical property testing (tensile, hardness, impact)

- Microstructure analysis and density verification

Powder Metallurgy FAQ Section 3

Q: Can Powder Metallurgy parts be heat treated?

A: Yes, many Powder Metallurgy materials can undergo heat treatment processes similar to wrought materials, including hardening, tempering, carburizing, and nitriding. The optimum heat treatment parameters may differ slightly due to the material's porosity, but we can achieve surface hardness up to 60 HRC with proper processing. Heat treatment can increase tensile strength by 30-50% while maintaining adequate toughness.

Q: What surface finishes are possible with Powder Metallurgy?

A: Standard as-sintered surfaces typically range from 1.6-3.2 μm Ra. Additional finishing options include sizing (improving dimensional accuracy and surface to 0.8-1.6 μm Ra), grinding (achieving 0.4-0.8 μm Ra), and various plating/coating processes. For porous applications, we can maintain controlled surface roughness for improved lubrication retention.

Technical Support and Design Assistance

Our Powder Metallurgy experts provide comprehensive technical support:

- Material selection guidance

- Design for manufacturability reviews

- Prototype development assistance

- Production process optimization

- Failure analysis and problem solving