- Home

- About Us

- Products

- Chain

- Sprocket

- Pulley & Sheave

- Gearbox\Reducer

- Belt

- Coupling

- Gear Operator &Valve

- Gear\Rack

- Mechanical seal

- Hub & Bushing

- Hydraulic & Pheumatic

- Shaft Collar

- Locking Assembly

- PTO Shaft

- Mechanical parts

- Conveyor component

- universal joints

- Shaft & York

- vibrator, vibration motor

- Starter & Alternator

- Ungrouped

- Other

- Air Compressor

- News

- Download

- Send Inquiry

- Contact Us

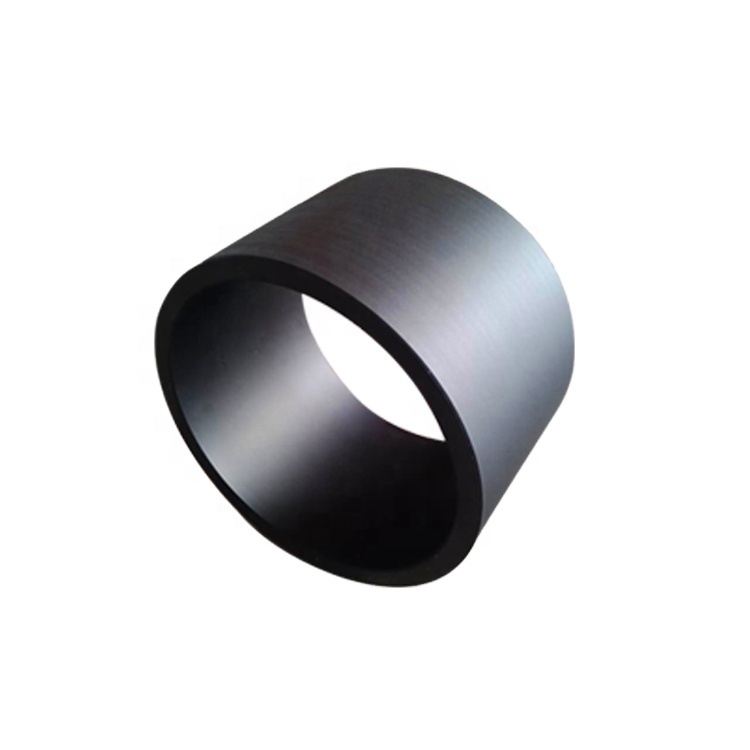

Shaft Collar

High-Quality Shaft Collars for Precision Applications

Shaft collars are essential components in mechanical systems, providing reliable positioning and locking capabilities for rotating shafts. Our premium shaft collar solutions are engineered to meet the most demanding industrial requirements while offering exceptional value.

Key Features of Our Shaft Collars

- Precision Machining: Tight tolerances ensure perfect fit and consistent performance

- Durable Materials: Available in various grades of steel, stainless steel, and aluminum

- Multiple Locking Mechanisms: Set screw, clamp-style, and two-piece collar options

- Corrosion Resistance: Special coatings and material options for harsh environments

- Standard and Custom Sizes: Extensive inventory covering shaft diameters from 1/8" to 6"

Technical Specifications

| Parameter | Standard Range | Special Options |

|---|---|---|

| Shaft Diameter | 1/8" - 4" | Up to 6" available |

| Material | Carbon Steel, Stainless Steel 304/316 | Aluminum, Brass, Plastic |

| Bore Tolerance | ±0.001" | ±0.0005" (precision grade) |

| Surface Finish | 32-64 µin Ra | Electropolished, Black Oxide, Zinc Plated |

| Temperature Range | -40°F to 400°F | -100°F to 800°F (special materials) |

How to Select the Right Shaft Collar

When choosing shaft collars for your application, consider these critical factors:

- Shaft Size: Measure the exact diameter where the collar will be positioned

- Load Requirements: Calculate axial and radial forces the collar must withstand

- Environmental Conditions: Consider temperature, moisture, and chemical exposure

- Installation Method: Evaluate space constraints for tool access during installation

- Maintenance Needs: Determine if frequent adjustments will be required

Shaft Collar FAQ #1: What's the difference between set screw and clamp-style shaft collars?

Set screw shaft collars use one or more screws that press directly against the shaft, creating friction to hold position. They're economical and work well for light to moderate loads. Clamp-style collars provide 360-degree clamping force without marring the shaft, offering more holding power and better concentricity for precision applications.

Shaft Collar FAQ #2: How do I prevent shaft collars from slipping under vibration?

For high-vibration environments, we recommend: 1) Using clamp-style collars instead of set screw types, 2) Selecting collars with serrated inner surfaces for better grip, 3) Applying shaft retaining compounds (like Loctite) beneath the collar, and 4) Using dual collars with opposing set screws that create a locking effect between them.

Shaft Collar FAQ #3: Can shaft collars be used for thrust bearing applications?

While shaft collars can provide basic axial positioning, they're not designed as primary thrust bearings. For applications with significant axial loads, we recommend using proper thrust bearings in conjunction with shaft collars. The collar can serve as a secondary stop or for mounting the bearing, but shouldn't bear continuous heavy thrust loads alone.

Installation Best Practices

Proper installation ensures optimal performance and longevity of your shaft collars:

- Clean the shaft surface thoroughly before installation

- For set screw collars, position the screw over a flat spot on the shaft if available

- Tighten screws gradually in a crisscross pattern for clamp-style collars

- Use torque wrenches when specified to avoid under/over-tightening

- Apply thread locker to set screws in vibration-prone applications

Industry Applications

Shaft collars serve critical functions across numerous industries:

| Industry | Typical Use Cases |

|---|---|

| Manufacturing | Conveyor systems, gearbox assemblies, spindle retention |

| Agriculture | Tractor PTO shafts, harvesting equipment adjustments |

| Automotive | Drive shaft positioning, accessory belt tensioners |

| Robotics | Joint positioning, actuator shaft retention |

| Aerospace | Flight control surface linkages, engine component positioning |

Custom Shaft Collar Solutions

For applications requiring special configurations, we offer custom shaft collar services:

- Non-standard bore sizes and configurations

- Custom outer diameters for specific housing fits

- Special material combinations

- Unique locking mechanisms

- Proprietary surface treatments

All custom shaft collars are manufactured to your exact specifications with the same quality standards as our standard product line.

Shaft Collar