- Home

- About Us

- Products

- Chain

- Sprocket

- Pulley & Sheave

- Gearbox\Reducer

- Belt

- Coupling

- Gear Operator &Valve

- Gear\Rack

- Mechanical seal

- Hub & Bushing

- Hydraulic & Pheumatic

- Shaft Collar

- Locking Assembly

- PTO Shaft

- Mechanical parts

- Conveyor component

- universal joints

- Shaft & York

- vibrator, vibration motor

- Starter & Alternator

- Ungrouped

- Other

- Air Compressor

- News

- Download

- Send Inquiry

- Contact Us

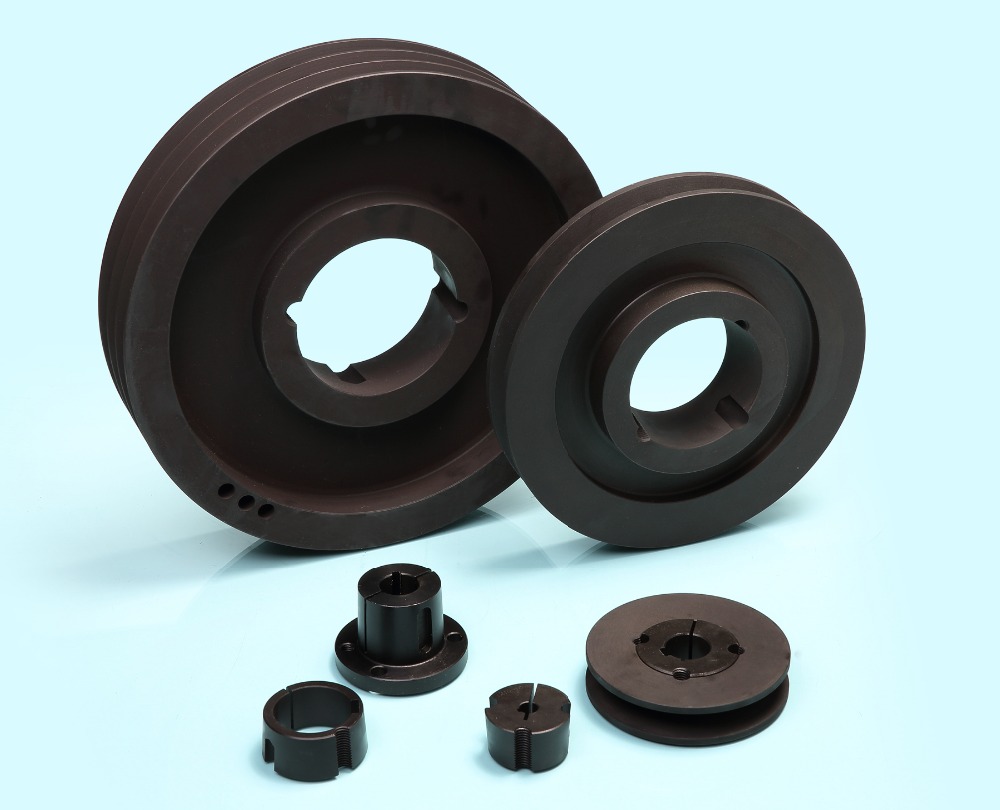

Hub & Bushing

Premium Hub & Bushing Solutions for Industrial Applications

As a leading manufacturer of precision components, we specialize in high-quality Hub & Bushing products that meet the most demanding industrial requirements. Our products are engineered for durability, precision performance, and long service life across various applications including automotive, heavy machinery, and manufacturing equipment.

Key Features of Our Hub & Bushing Products:

- Manufactured from premium alloy steel for maximum durability

- Precision machined to tight tolerances (±0.005mm)

- Advanced heat treatment process ensures hardness (HRC 58-62)

- Multiple surface treatment options available (zinc plating, powder coating, etc.)

- Compatible with various lubrication systems

Standard Product Specifications:

| Parameter | Standard Range | Custom Options |

|---|---|---|

| Inner Diameter | 10mm - 200mm | Up to 500mm |

| Outer Diameter | 20mm - 300mm | Up to 600mm |

| Length | 15mm - 300mm | Up to 1000mm |

| Load Capacity | 5kN - 200kN | Up to 500kN |

| Temperature Range | -40°C to +150°C | -60°C to +300°C |

Material Options:

| Material Grade | Properties | Best For |

|---|---|---|

| SAE 4140 | High tensile strength, good fatigue resistance | Heavy-duty applications |

| SAE 8620 | Excellent case hardening properties | Wear-resistant applications |

| Stainless Steel 304 | Corrosion resistant, moderate strength | Food processing, marine environments |

| Bronze Alloy | Self-lubricating, good thermal conductivity | High-temperature applications |

Hub & Bushing FAQ Section 1:

Question: What is the typical lead time for standard Hub & Bushing products?

Answer: Our standard Hub & Bushing products typically ship within 5-7 business days from order confirmation. For custom specifications or large quantity orders, lead time may extend to 2-3 weeks depending on complexity. We maintain substantial inventory of our most popular sizes to ensure quick turnaround for emergency replacements.

Installation Guidelines:

Proper installation is crucial for optimal performance of Hub & Bushing components. Follow these steps for best results:

- Clean all mating surfaces thoroughly before installation

- Apply recommended lubricant to both inner and outer surfaces

- Use proper press-fit tools with controlled pressure

- Ensure proper alignment during installation

- Check clearance and rotation after installation

Hub & Bushing FAQ Section 2:

Question: How often should Hub & Bushing components be lubricated?

Answer: Lubrication intervals for Hub & Bushing components depend on operating conditions. For standard industrial applications, we recommend relubrication every 250-500 operating hours. In high-speed or high-temperature environments, lubrication intervals should be reduced to 100-200 hours. Always use manufacturer-recommended lubricants and follow the specific maintenance schedule for your equipment.

Customization Options:

We understand that standard solutions don't always meet specific application requirements. Our engineering team can develop custom Hub & Bushing solutions with:

- Special material compositions

- Unique dimensional configurations

- Custom surface treatments

- Integrated sensor capabilities

- Special mounting features

Quality Assurance:

Every Hub & Bushing product undergoes rigorous quality control:

| Test | Standard | Method |

|---|---|---|

| Dimensional Accuracy | ISO 286 | Coordinate measuring machine |

| Hardness | ASTM E18 | Rockwell hardness tester |

| Surface Finish | ISO 1302 | Surface profilometer |

| Material Composition | ASTM E415 | Spectrochemical analysis |

Hub & Bushing FAQ Section 3:

Question: What are the signs that a Hub & Bushing needs replacement?

Answer: Common indicators that your Hub & Bushing requires replacement include: excessive play or looseness in the assembly, unusual noise during operation (squeaking or grinding), visible wear or scoring on the contact surfaces, increased vibration, and difficulty in maintaining proper alignment. Regular inspection is recommended as part of preventive maintenance to identify wear before failure occurs. We suggest replacing Hub & Bushing components at the first signs of significant wear to prevent damage to other machine elements.

Industry Applications:

Our Hub & Bushing products serve critical functions across multiple industries:

| Industry | Typical Application | Key Requirements |

|---|---|---|

| Automotive | Steering systems, suspension components | High precision, vibration damping |

| Construction | Heavy equipment pivots | High load capacity, dirt resistance |

| Manufacturing | Industrial machinery | Wear resistance, long service life |

| Agriculture | Tractor components | Corrosion resistance, impact strength |

Technical Support:

Our engineering team provides comprehensive technical support for all Hub & Bushing applications. Services include:

- Application analysis and product selection

- Failure mode diagnosis

- Custom design consultation

- Installation and maintenance training

Hub & Bushing