- Home

- About Us

- Products

- Chain

- Sprocket

- Pulley & Sheave

- Gearbox\Reducer

- Belt

- Coupling

- Gear Operator &Valve

- Gear\Rack

- Mechanical seal

- Hub & Bushing

- Hydraulic & Pheumatic

- Shaft Collar

- Locking Assembly

- PTO Shaft

- Mechanical parts

- Conveyor component

- universal joints

- Shaft & York

- vibrator, vibration motor

- Starter & Alternator

- Ungrouped

- Other

- Air Compressor

- News

- Download

- Send Inquiry

- Contact Us

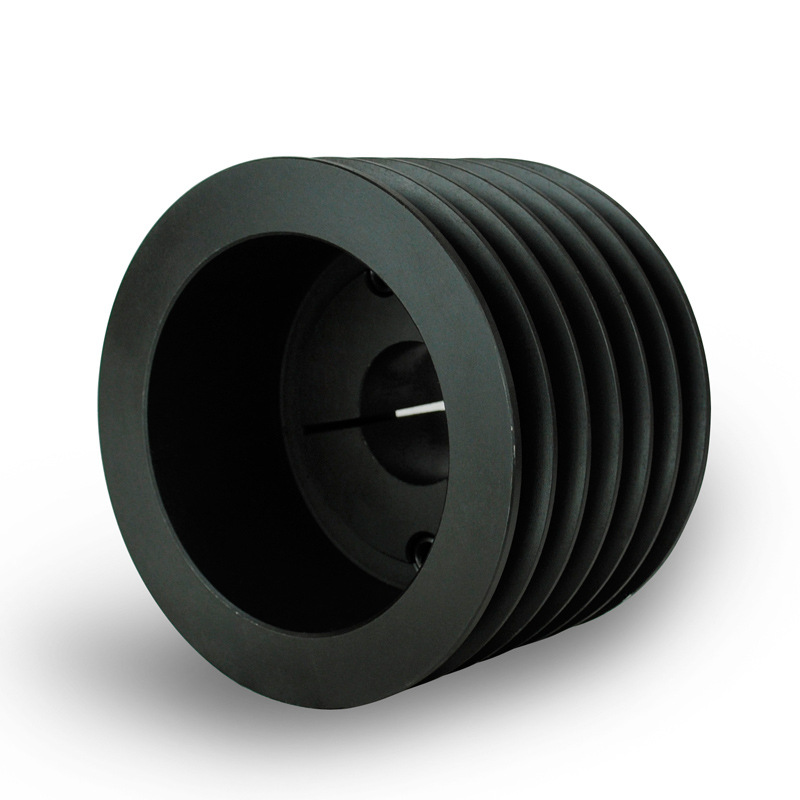

V belt Pulley

Raydafon V Belt Pulleys: Precision Power Transmission Components from China's Leading Manufacturer

For industrial buyers requiring reliable V belt pulleys, performance consistency and rapid availability are critical. Raydafon, a premier China V belt pulley manufacturer, produces high-efficiency pulleys for agricultural equipment, HVAC systems, industrial machinery, and automotive applications. As specialized suppliers with full OEM/ODM capabilities, we deliver customized V belt pulley solutions with 25-day standard lead times and factory-direct wholesale pricing.

Raydafon V Belt Pulley Product Specifications

Comprehensive Product Line

- Classical V-Belt Pulleys (A, B, C, D section profiles)

- Narrow V-Belt Pulleys (3V, 5V, 8V series)

- Double-Groove Pulleys (AX, BX, CX configurations)

- Variable Pitch Pulleys (Adjustable center distances)

- Taper Lock Bush Pulleys (3030, 3535, 4040 series)

Technical Specification Comparison

| Parameter | Standard Duty | Heavy Duty | Precision Grade |

|---|---|---|---|

| Material | HT250 Cast Iron | Ductile Iron 450-10 | Aluminum 6061-T6 |

| Bore Range | 10-200mm | 20-300mm | 5-250mm |

| Groove Finish | Machined | Ground | Polished |

| Balance Grade | G16 | G6.3 | G2.5 |

| Max RPM | 3,500 | 2,800 | 6,500 |

| Temp Range | -30°C~120°C | -40°C~150°C | -50°C~180°C |

Key Manufacturing Advantages

- Precision CNC Turning (±0.02mm concentricity tolerance)

- Dynamic Balancing (ISO 1940-1 compliant)

- Interchangeable Profiles (Matched to Gates, Bando standards)

- Anti-Corrosion Options (Zinc plating, powder coating available)

Addressing Common V Belt Pulley Purchasing Challenges

1. Premature Groove Wear

Raydafon Solution:

- Hardened groove surfaces (HRC 45-50)

- Stress-relieved castings prevent microcracking

- Optional hardened steel inserts for extreme conditions

2. Misalignment Issues

Raydafon Solution:

- Laser-aligned machining centers

- Integrated keyway/set screw positioning

- Dimensional inspection reports with each shipment

3. Long Custom Lead Times

Raydafon Advantage:

- 15-day rush service for modified standards

- Digital pattern library for common modifications

- No MOQ for sample prototypes

V Belt Pulley FAQ - Expert Purchasing Guidance

Q1: How do I determine the correct V belt pulley size for my application?

A: Three critical measurements are required:

- Pitch Diameter (PD): Measure where belts ride in grooves

- Bore Size: Shaft diameter with proper clearance fit

-

Groove Profile: Match belt section (A/B/C/D or 3V/5V/8V)

Raydafon provides free sizing assistance with CAD drawings.

Q2: What maintenance extends V belt pulley service life?

A: Implement these best practices:

- Monthly Inspections: Check for groove glazing/wear

- Proper Tensioning: Use tension gauges (avoid over-tightening)

-

Alignment Checks: Maximum 0.5° angular misalignment

Our pulleys include wear indicators for easy monitoring.

Q3: Can you supply pulleys matching obsolete equipment specifications?

A: Raydafon specializes in legacy system support:

- Reverse engineering from samples

- Pattern recreation for discontinued models

-

Material upgrades to improve original designs

Submit drawings/photos for immediate feasibility analysis.

Industry-Specific Applications

Agricultural Implement Solutions

- Self-cleaning groove designs for combine harvesters

- Weather-resistant coatings for irrigation pumps

Industrial Power Transmission

- High-inertia pulleys for crusher applications

- Static-dissipative versions for explosive environments

Commercial HVAC Systems

- Noise-optimized aluminum pulleys

- Maintenance-free bushing options

Raydafon Quality Assurance Protocol

✔ Material Certification (Full traceability)

✔ 100% Dimensional Verification (CMM inspection)

✔ Performance Testing (Rigorous dyno evaluations)

✔ Packaging Protection (Custom crating available)

Why Global Buyers Choose Raydafon

✓ 16 Years Specialization in power transmission components

✓ 80% Repeat Client Rate across 45 countries

✓ Engineering Support from prototype to production

V belt Pulley