- Home

- About Us

- Products

- Chain

- Sprocket

- Pulley & Sheave

- Gearbox\Reducer

- Belt

- Coupling

- Gear Operator &Valve

- Gear\Rack

- Mechanical seal

- Hub & Bushing

- Hydraulic & Pheumatic

- Shaft Collar

- Locking Assembly

- PTO Shaft

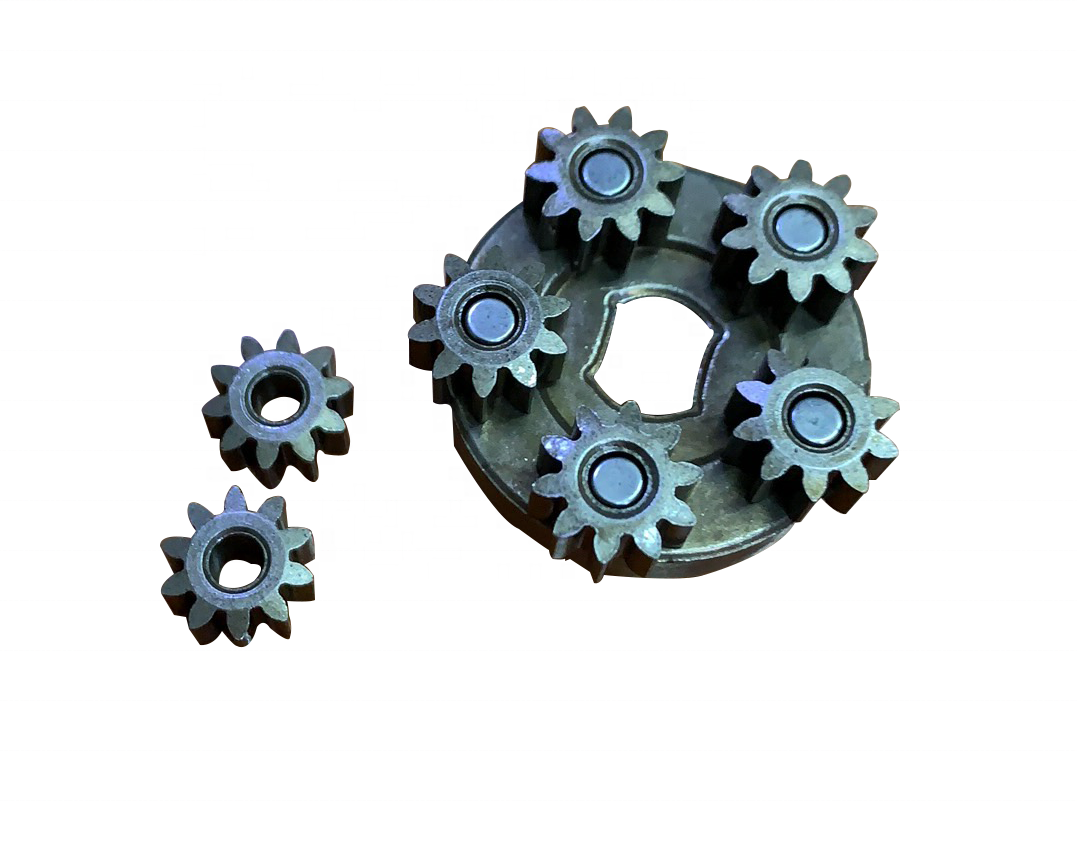

- Mechanical parts

- Conveyor component

- universal joints

- Shaft & York

- vibrator, vibration motor

- Starter & Alternator

- Ungrouped

- Other

- Air Compressor

- News

- Download

- Send Inquiry

- Contact Us

Mechanical parts

When it comes to industrial applications, high-quality mechanical parts are essential for ensuring optimal performance and longevity of your equipment. Our comprehensive selection of mechanical parts meets rigorous industry standards, offering reliability and precision for various applications.

Premium Mechanical Parts Specifications

Our mechanical parts are manufactured using advanced techniques and superior materials to deliver exceptional durability and performance. Below are the technical specifications of our standard product line:

Key Features:

- Material Grade: 304/316 Stainless Steel, Carbon Steel, Alloy Steel

- Tolerance: ±0.005 mm to ±0.01 mm

- Surface Finish: 0.4μm to 3.2μm Ra

- Heat Treatment: Annealed, Quenched & Tempered

- Corrosion Resistance: Salt Spray Test 500+ hours

- Load Capacity: Up to 50 tons depending on configuration

Standard Mechanical Parts Dimensions

| Part Type | Diameter (mm) | Length (mm) | Weight (kg) | Working Temp Range (°C) |

|---|---|---|---|---|

| Bearing Housing | 20-500 | 30-600 | 0.5-85 | -40 to 120 |

| Gear Shaft | 10-300 | 50-2000 | 1.2-150 | -20 to 150 |

| Hydraulic Cylinder | 25-400 | 100-3000 | 3.5-280 | -30 to 200 |

Mechanical Parts FAQ

Q: What maintenance do mechanical parts require?

A: Regular maintenance for mechanical parts includes lubrication every 500 operating hours, inspection for wear every 3 months, and replacement of seals annually. For high-load applications, we recommend monthly inspections and using our premium lubricant series specifically formulated for heavy-duty mechanical parts.

Q: How do I choose the right material for my mechanical parts?

A: Material selection depends on your operating environment. For corrosive conditions, 316 stainless steel mechanical parts are recommended. High-temperature applications require alloy steel, while carbon steel offers the best cost-performance ratio for standard industrial use. Our engineering team can help analyze your specific requirements.

Q: What certifications do your mechanical parts have?

A: Our mechanical parts meet ISO 9001:2015, ASME B18, and DIN standards. Pressure components are PED certified, and our aerospace-grade parts have AS9100D certification. All products come with complete material traceability documentation and quality inspection reports.

Application-Specific Mechanical Parts Solutions

We provide customized mechanical parts for various industries:

- Automotive: Precision gears with noise reduction technology

- Aerospace: High-strength titanium alloy components

- Energy: Corrosion-resistant parts for offshore applications

- Manufacturing: High-wear components with extended service life

Quality Assurance Process

Every mechanical part undergoes rigorous testing:

- Material composition verification via spectroscopy

- Dimensional accuracy check with CMM machines

- Surface roughness measurement

- Hardness testing (Rockwell/Brinell scale)

- Functional testing under simulated working conditions

Mechanical Parts Packaging Options

| Part Size | Standard Packaging | Special Requirements |

|---|---|---|

| Small (<5kg) | Plastic containers with anti-corrosion paper | Vacuum sealing available |

| Medium (5-50kg) | Wooden crates with foam protection | Desiccant packs included |

| Large (>50kg) | Custom steel-frame containers | Weatherproof wrapping available |

Why Choose Our Mechanical Parts?

With over two decades of experience in precision engineering, we offer:

- 30% longer service life compared to industry average

- Custom engineering solutions within 72 hours

- Global logistics network with 15 strategically located warehouses

- Competitive pricing with volume discounts

- 24/7 technical support from our engineering team

Mechanical parts