- Home

- About Us

- Products

- Chain

- Sprocket

- Pulley & Sheave

- Gearbox\Reducer

- Belt

- Coupling

- Gear Operator &Valve

- Gear\Rack

- Mechanical seal

- Hub & Bushing

- Hydraulic & Pheumatic

- Shaft Collar

- Locking Assembly

- PTO Shaft

- Mechanical parts

- Conveyor component

- universal joints

- Shaft & York

- vibrator, vibration motor

- Starter & Alternator

- Ungrouped

- Other

- Air Compressor

- News

- Download

- Send Inquiry

- Contact Us

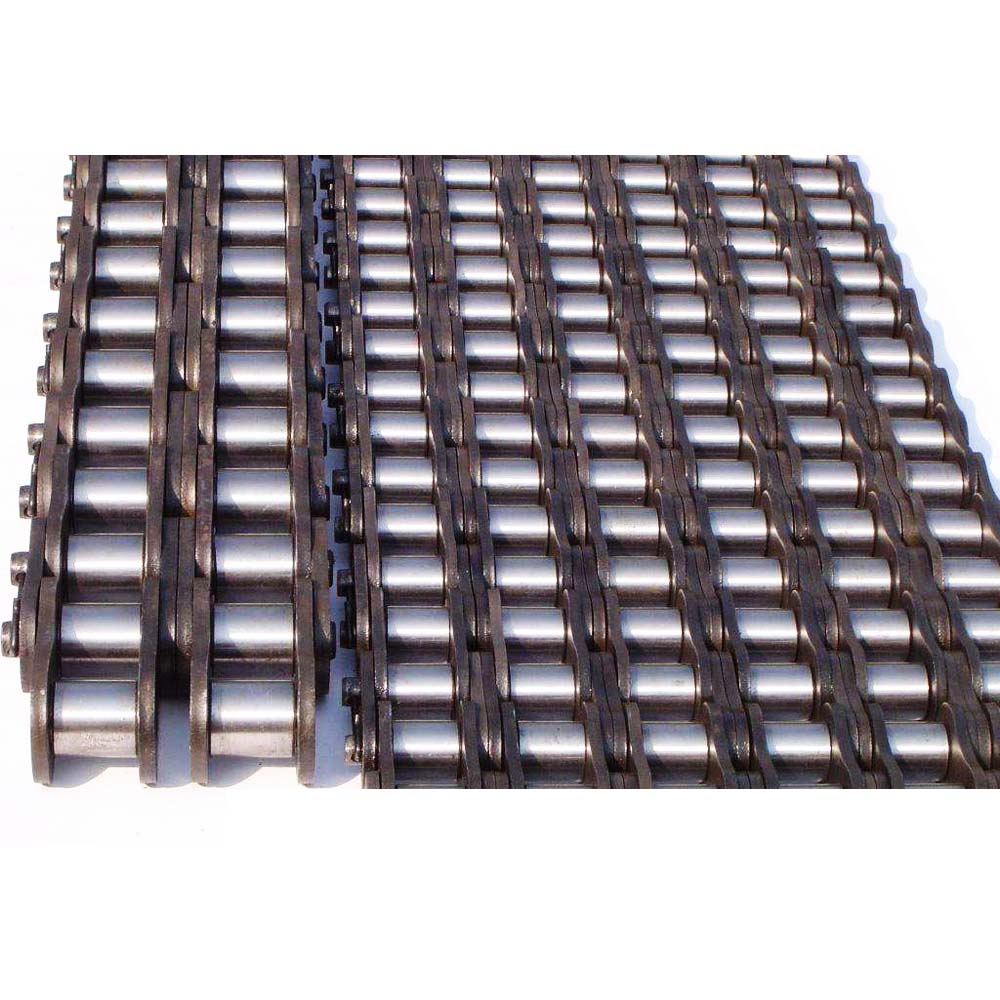

Chain

Raydafon Industrial Chains: Premium Power Transmission Solutions from China's Top Manufacturer

Industrial buyers worldwide trust Raydafon chains for durable, high-performance power transmission and material handling applications. As a leading China chain manufacturer, we specialize in roller chains, conveyor chains, and specialty chains with OEM/ODM capabilities, offering customized chain solutions at competitive wholesale prices.

This guide provides detailed chain specifications, addresses common buyer concerns, and explains why global buyers choose Raydafon chains for reliability and efficiency.

Raydafon Chain Product Range & Technical Specifications

1. Chain Types Available

✔ Roller Chains (ANSI, DIN, ISO standards)

✔ Conveyor Chains (Single-flex, double-flex designs)

✔ Leaf Chains (High-tensile lifting applications)

✔ Silent Chains (Precision power transmission)

✔ Specialty Chains (Stainless steel, nickel-plated, corrosion-resistant)

2. Performance Comparison Table

| Parameter | Standard Roller Chain | Heavy-Duty Chain | Stainless Steel Chain |

|---|---|---|---|

| Material | Carbon Steel (AISI 1045) | Alloy Steel (4140) | SS304 / SS316 |

| Tensile Strength | 8,000 - 12,000 lbs | 15,000 - 25,000 lbs | 6,000 - 10,000 lbs |

| Surface Finish | Zinc-plated / Black oxide | Heat-treated | Passivated |

| Temperature Range | -20°C to 120°C | -30°C to 200°C | -50°C to 400°C |

| Certifications | ISO 606, ANSI B29.1 | ISO 1395, AGMA | FDA, USDA compliant |

3. Why Choose Raydafon Chains?

✅ Factory-direct pricing – No middlemen, lower costs

✅ Fast production & shipping – 20-day standard lead time

✅ Full customization – Size, material, coating, packaging

✅ Strict quality control – 100% load testing & dimensional checks

Solving Common Chain Purchasing Challenges

1. Premature Wear & Chain Stretch

-

Raydafon Solution:

- Precision heat-treated pins & bushings

- Pre-stretched chains for long-term stability

- Optional hardened rollers for abrasive environments

2. Long Delivery Times from Suppliers

-

Raydafon Advantage:

- 8,000+ chains in stock for immediate dispatch

- Express production lines for urgent orders

- Global logistics partnerships (DHL, FedEx, sea freight)

3. Difficulty in Custom Chain Specifications

-

Raydafon Custom Service:

- CAD-driven chain design for unique applications

- Special pitch lengths, attachments, and coatings

- Small MOQ (from 50 pieces for custom orders)

Industrial Chain FAQ – Expert Buyer’s Guide

Q1: What’s the difference between ANSI and ISO roller chains?

A: Key differences include:

- ANSI chains (US standard): Measured in inches (e.g., #40, #60)

-

ISO chains (Metric standard): Measured in millimeters (e.g., 08B, 12B)

Raydafon produces both standards with full interchangeability.

Q2: How often should industrial chains be lubricated?

A: Lubrication frequency depends on:

- Light-duty use: Every 100 hours

- Heavy-duty use: Every 8-24 hours

- Self-lubricating chains available for maintenance-free applications

Q3: Can you manufacture chains for food-grade applications?

A: Yes, we offer:

- Stainless steel chains (SS304/SS316)

- FDA-compliant coatings

- Hygienic design (easy-clean, no crevices)

Industry Applications & Success Stories

Material Handling

- Pallet conveyor chains with 3X lifespan vs. industry average

- Mining chains with reinforced links for extreme loads

Agricultural Machinery

- Harvester chains with anti-corrosion treatment

- Grain elevator chains with self-cleaning rollers

Automotive Manufacturing

- Timing chains with ultra-low stretch

- Paint shop conveyor chains resistant to chemicals

Raydafon’s Manufacturing Excellence

✔ 18+ Years in Chain Production

✔ 50+ Export Markets Served

✔ In-House R&D for Custom Solutions

Chain