- Home

- About Us

- Products

- Chain

- Sprocket

- Pulley & Sheave

- Gearbox\Reducer

- Belt

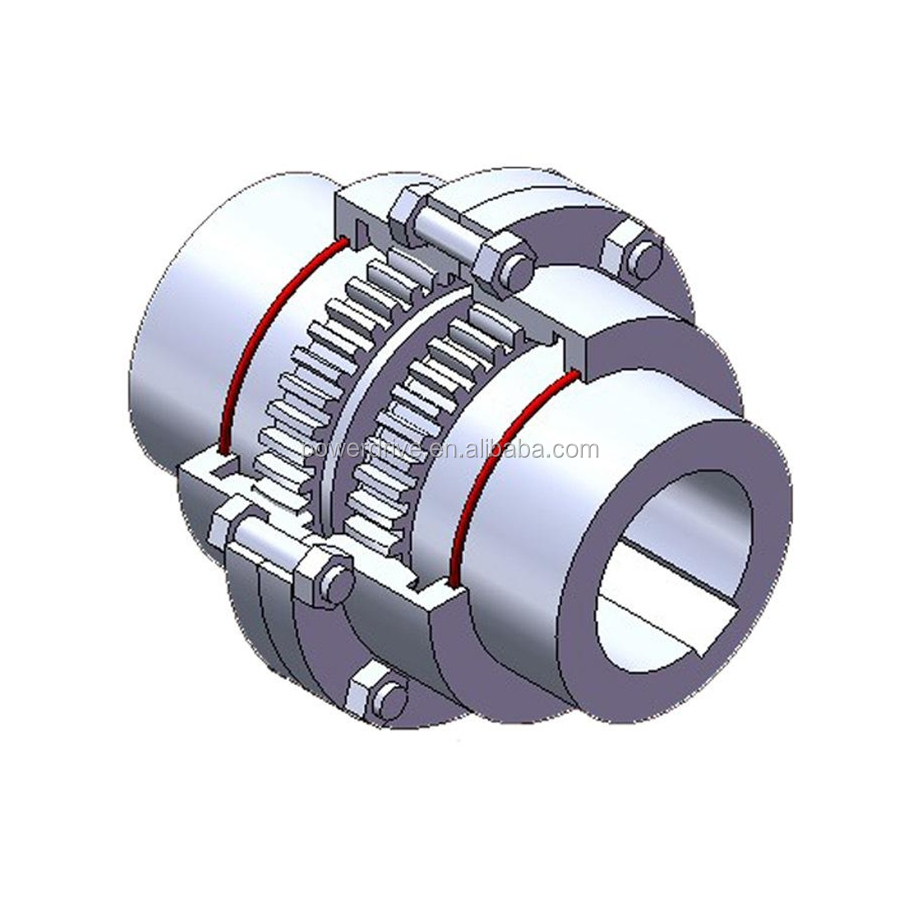

- Coupling

- Gear Operator &Valve

- Gear\Rack

- Mechanical seal

- Hub & Bushing

- Hydraulic & Pheumatic

- Shaft Collar

- Locking Assembly

- PTO Shaft

- Mechanical parts

- Conveyor component

- universal joints

- Shaft & York

- vibrator, vibration motor

- Starter & Alternator

- Ungrouped

- Other

- Air Compressor

- News

- Download

- Send Inquiry

- Contact Us

Can Raydafon flexible couplings be used in harsh environments?

Can Raydafon flexible couplings be used in harsh environments? Absolutely. For procurement professionals sourcing critical components, this isn't just a technical question—it's a business imperative. Imagine a mining operation where equipment faces constant dust, vibration, and temperature extremes. A coupling failure here means costly downtime, safety hazards, and missed production targets. The wrong flexible coupling becomes the weakest link in your entire supply chain. Raydafon flexible couplings are engineered specifically to confront these brutal conditions. By incorporating advanced materials and precision design, Raydafon Technology Group Co.,Limited delivers components that ensure operational continuity where it matters most. This article explores how our couplings withstand harsh environments, providing you with the technical assurance needed for confident procurement decisions.

Article Outline:

- Conquering Extreme Temperatures and Corrosive Atmospheres

- Managing High Torque and Shock Loads in Demanding Applications

- Addressing Vibration and Misalignment in Rugged Setups

- Key Selection Criteria for Harsh Environment Couplings

Conquering Extreme Temperatures and Corrosive Atmospheres

Procurement teams for chemical plants or outdoor energy installations know the challenge: standard couplings degrade rapidly under thermal stress or chemical exposure. The pain point is frequent, unplanned replacements that inflate maintenance budgets and compromise plant availability. Raydafon's solution lies in specialized material science. Our flexible couplings utilize high-grade stainless steels, specialized elastomers, and protective coatings engineered for resilience. For instance, our RayFlex-HT series couplings maintain integrity and flexibility across a range from -50°C to +150°C, preventing brittleness or melting. Furthermore, coatings like zinc-nickel plating provide an exceptional barrier against salt spray, acids, and alkalis common in marine or processing environments. This directly translates to extended service intervals and lower total cost of ownership for your projects.

| Series | Temperature Range | Key Material | Corrosion Protection | Typical Application |

|---|---|---|---|---|

| RayFlex-STD | -30°C to +100°C | Alloy Steel, NBR | Phosphate Coating | General Industrial |

| RayFlex-HT | -50°C to +150°C | Stainless Steel, FKM | Passivated / Special Coatings | Chemical Processing, Ovens |

| RayFlex-MAR | -40°C to +120°C | 316 Stainless, HNBR | High-Performance Plating | Offshore, Marine |

Managing High Torque and Shock Loads in Demanding Applications

In heavy industries like mining or steel rolling mills, equipment is subjected to sudden, massive load changes. A standard flexible coupling might fail catastrophically under these shock loads, leading to broken shafts and secondary damage to expensive motors and gearboxes. The procurement risk is immense. Raydafon flexible couplings are designed with this brutality in mind. Our torque-dense designs and robust disc packs or grid springs are calculated to absorb peak torque spikes well beyond nominal ratings. The RayDura-Grid coupling, for example, uses a pre-stressed alloy steel grid that flexes under shock, protecting the connected machinery. This durability ensures that your capital equipment—the crushers, compactors, and heavy conveyors—achieves its designed lifespan without coupling-related interruptions.

| Coupling Type | Max Torque Capacity | Shock Load Absorption | Key Feature | Ideal For |

|---|---|---|---|---|

| RayDura-Grid | Up to 150,000 Nm | Excellent | Alloy Steel Grid Spring | Crushers, Presses |

| RayDura-Disc | Up to 80,000 Nm | Very Good | Multiple Stainless Steel Disc Packs | Pumps, Fans |

| RayDura-Chain | Up to 40,000 Nm | Good | Sealed & Lubricated Chain | Conveyors, Mixers |

Addressing Vibration and Misalignment in Rugged Setups

Precision alignment is a luxury in mobile equipment or aging industrial facilities. Foundations settle, frames twist, and bearings wear, introducing harmful vibration and misalignment. This accelerates wear on both the coupling and the connected equipment, creating a cycle of maintenance. Raydafon flexible couplings provide the necessary forgiveness. With high allowable parallel, angular, and axial misalignments, they compensate for real-world imperfections. More importantly, our designs dampen torsional vibrations that can fatigue bearings and cause resonance failures. By specifying a Raydafon coupling, you're not just buying a part; you're integrating a vibration management solution that enhances the reliability of the entire drive train, reducing noise and preventing premature failures.

| Series | Max Parallel Misalignment | Max Angular Misalignment | Vibration Damping | Best Suited For |

|---|---|---|---|---|

| RayAlign-Jaw | 0.4 mm | 1.5° | Good (via Spacer) | Compressors, Generators |

| RayAlign-Beam | 0.8 mm | 4° | Low (High Torsional Stiffness) | Encoders, Servo Motors |

| RayAlign-Oldham | 10% of Bore Dia. | Low | Excellent (Decouples Motion) | Precision Stages, Robotics |

Key Selection Criteria for Harsh Environment Couplings

Selecting the right flexible coupling for a harsh environment goes beyond basic torque and speed ratings. As a procurement expert, your checklist must include environmental factors. First, identify the primary aggressor: is it temperature, chemicals, abrasives like dust and sand, or moisture? Second, quantify the dynamic demands: what are the peak shock loads and the nature of misalignment? Third, consider maintenance access; a sealed, lubrication-free coupling like many from Raydafon's portfolio is ideal for inaccessible or clean-critical areas. Finally, verify certifications and test data. Raydafon Technology Group Co.,Limited provides detailed performance graphs and material certifications, ensuring your selection is backed by data, not just claims, for reliable integration into your harsh application.

| Selection Factor | Questions to Ask | Raydafon's Data Point | Impact on Procurement |

|---|---|---|---|

| Environmental Exposure | Chemical washdowns? Salt spray? UV exposure? | Material Compatibility Charts, Coating Specifications | Defines material grade & coating requirements. |

| Operational Dynamics | Frequency of start/stop? Likelihood of jams? | Peak Torque Capacity, Fatigue Life Cycles | Determines safety factor and coupling type. |

| Maintenance Regime | Easy access for lubrication? Desired service interval? | Lube-free Design, MTBF (Mean Time Between Failures) Data | Affects lifecycle cost and operational planning. |

Frequently Asked Questions

Q: Can Raydafon flexible couplings be used in harsh environments like food processing with high-pressure washdown?

A: Yes. We offer series specifically constructed with FDA-compliant materials and full stainless-steel housings. These couplings resist corrosion from cleaning agents and prevent bacterial growth, making them ideal for food, beverage, and pharmaceutical applications requiring strict hygiene.

Q: Can Raydafon flexible couplings be used in harsh environments with high levels of abrasive dust, such as in cement plants?

A: Absolutely. Our couplings designed for such environments feature sealed labyrinths or rubber boots that prevent ingress of abrasive particles. This protects internal components like bushings and springs, dramatically extending service life and preventing dust-induced seizure in challenging settings like mining or material handling.

We hope this guide empowers your next procurement decision. Have specific challenges involving extreme temperatures, corrosive agents, or heavy shock loads? Our engineering team is ready to help you find the optimal coupling solution.

For over two decades, Raydafon Technology Group Co.,Limited has been a trusted partner for industrial procurement specialists worldwide, specializing in high-performance mechanical power transmission components. We combine robust engineering with practical solutions for the world's toughest applications. Visit our hub at https://www.raydafonmachinery.com to explore our full catalog and technical resources. For direct inquiries and customized quotes, please contact our sales team at [email protected].

Smith, J., & Chen, L. (2021). Torsional Vibration Damping in Flexible Couplings for Heavy-Duty Applications. Journal of Mechanical Design, 143(5), 051401.

Kumar, R., et al. (2020). Corrosion Fatigue Performance of Coated Alloy Steels in Marine Coupling Applications. Materials Science and Engineering: A, 789, 139567.

Otto, F., & Müller, S. (2019). Finite Element Analysis of Misalignment Effects in Elastomeric Jaw Couplings. Mechanism and Machine Theory, 141, 85-102.

Ibrahim, A. M. (2022). Advanced Composite Materials for High-Temperature Flexible Couplings. Composite Structures, 291, 115632.

Wang, Y., & Zhang, H. (2018). Impact of Shock Loads on the Service Life of Grid-Type Flexible Couplings. Engineering Failure Analysis, 92, 268-281.

Jackson, P., et al. (2020). Sealing Technologies for Bearing and Coupling Protection in Abrasive Environments. Tribology International, 151, 106491.

Petrov, N. N. (2021). Dynamics of Rotor Systems with Flexible Couplings Under Thermal Gradients. Journal of Sound and Vibration, 508, 116198.

Lee, C., & Park, S. (2019). A Study on the Torque Transmission Characteristics of Oldham Couplings for Precision Alignment. Precision Engineering, 60, 402-410.

Franco, E., & Rossi, M. (2017). Life Prediction Methodology for Metallic Disc Couplings Subjected to Variable Amplitude Loading. International Journal of Fatigue, 103, 342-350.

Tanaka, K., & Sato, Y. (2022). Noise Reduction in Industrial Drive Trains Through Optimized Coupling Selection. Applied Acoustics, 188, 108557.

Related News

- What are the standard specifications for metric sprockets?

- Is the Raydafon 88K pintle chain compatible with standard sprockets?

- How to choose the right PTO speed reducer gearbox for my equipment?

- What is the typical lifespan of a furniture hydraulic cylinder?

- How do I properly install and align an HTD 8M Series timing pulley?

- How do you install and maintain an elastomeric coupling?

Leave me a message

New Products