- Home

- About Us

- Products

- Chain

- Sprocket

- Pulley & Sheave

- Gearbox\Reducer

- Belt

- Coupling

- Gear Operator &Valve

- Gear\Rack

- Mechanical seal

- Hub & Bushing

- Hydraulic & Pheumatic

- Shaft Collar

- Locking Assembly

- PTO Shaft

- Mechanical parts

- Conveyor component

- universal joints

- Shaft & York

- vibrator, vibration motor

- Starter & Alternator

- Ungrouped

- Other

- Air Compressor

- News

- Download

- Send Inquiry

- Contact Us

How do you install and maintain an elastomeric coupling?

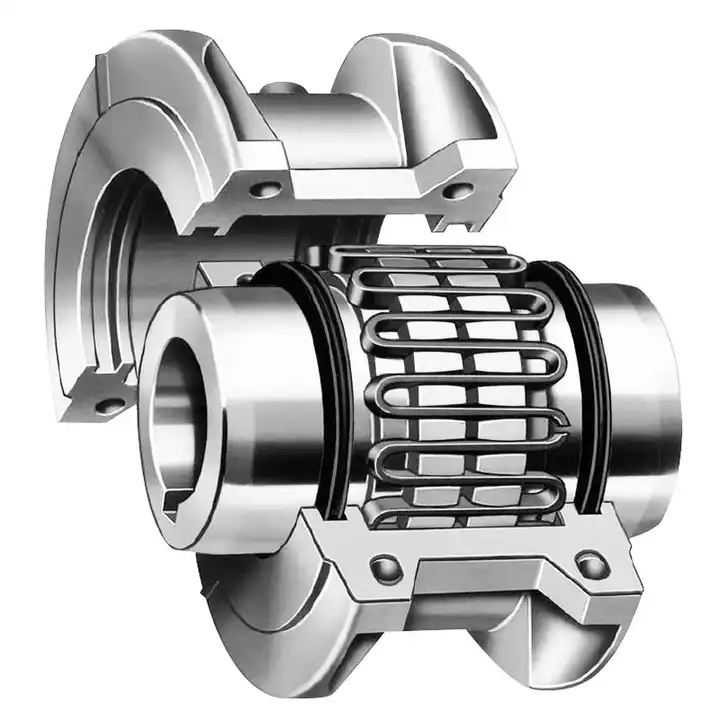

How do you install and maintain an elastomeric coupling? This is a critical question for anyone responsible for keeping industrial machinery running smoothly and efficiently. An elastomeric coupling, with its flexible, shock-absorbing element, is a cornerstone of reliable power transmission. However, improper installation and neglected maintenance can quickly turn this vital component into a source of costly downtime. A seized coupling or a sudden failure can halt an entire production line, leading to significant financial losses. This guide cuts through the complexity, providing clear, actionable steps to ensure your couplings deliver maximum performance and longevity. We'll walk you through the entire process, from initial inspection and correct shaft alignment to routine checks and troubleshooting common issues. For procurement specialists seeking not just components but comprehensive reliability, partnering with an expert manufacturer like Raydafon Technology Group Co.,Limited is a strategic move towards minimizing operational risk.

Article Outline:

- Avoiding Misalignment Headaches During Installation

- Implementing a Proactive Maintenance Schedule

- Troubleshooting Common Elastomeric Coupling Issues

- FAQs on Elastomeric Coupling Installation & Maintenance

Avoiding Misalignment Headaches During Installation

Picture this: a new pump is being commissioned, and after hours of work, the system is powered on only to produce excessive vibration and noise. The culprit is often hidden in the coupling installation. Proper installation is non-negotiable for elastomeric coupling performance. The primary goal is to achieve correct shaft alignment within the coupling's specified tolerance to prevent premature wear on the elastomer element and bearings.

Solution: Follow a meticulous, step-by-step process. First, clean the motor and driven equipment shaft ends thoroughly, removing any rust or burrs. Verify the bore sizes match the shafts precisely. Slide the coupling halves onto their respective shafts. For keyed connections, ensure the key is properly seated. The critical step is alignment. Use dial indicators or laser alignment tools to check for parallel and angular misalignment. Adjust the machine feet until alignment is within the coupling manufacturer's specifications. Finally, tighten the clamping screws or fasteners to the recommended torque using a calibrated torque wrench in a crisscross pattern to ensure even pressure. Never use impact wrenches, as they can damage the coupling.

Key Installation Parameters:

| Parameter | Typical Specification / Action |

|---|---|

| Shaft Cleanliness | Free of oil, dirt, and corrosion |

| Bore & Shaft Fit | Slip fit or light press fit as per design |

| Maximum Parallel Misalignment | 0.2 mm - 0.5 mm (Refer to Raydafon coupling datasheet) |

| Maximum Angular Misalignment | 1° - 3° (Refer to Raydafon coupling datasheet) |

| Fastener Torque | As specified by manufacturer (e.g., Raydafon Tech Sheet) |

Implementing a Proactive Maintenance Schedule

Even a perfectly installed coupling will fail without proper care. The maintenance manager reviewing last quarter's downtime report sees a recurring pattern of coupling-related failures. Reactive maintenance is costly. A proactive schedule transforms coupling care from a fire-fighting exercise into a predictable, planned activity.

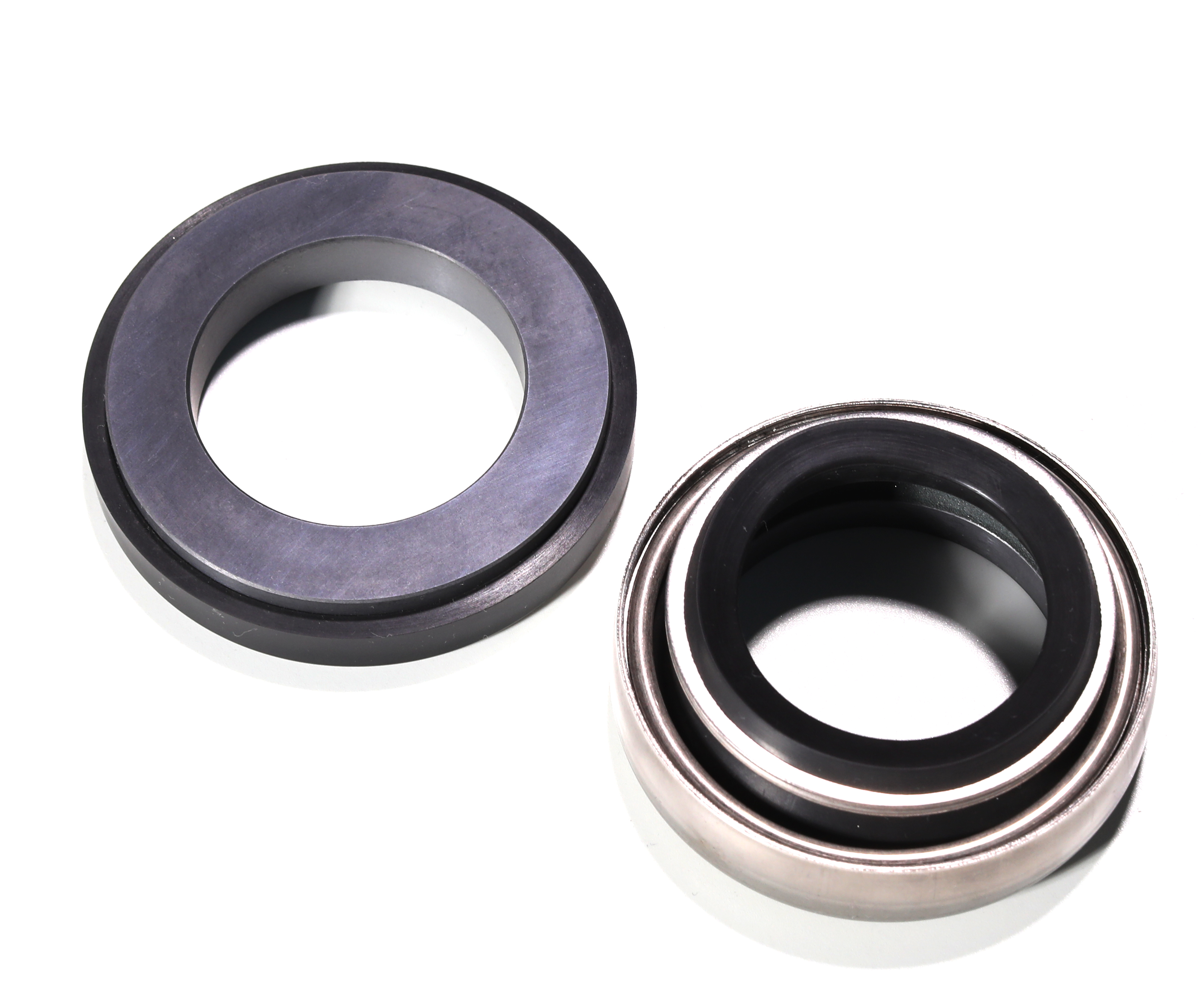

Solution: Establish a routine inspection protocol. The flexible elastomer element is the heart of the coupling and its primary wear item. Visually inspect it regularly for signs of cracking, hardening, permanent set, or chemical degradation. Check for unusual vibrations or temperature increases during operation, which indicate misalignment or overload. Listen for changes in noise. Periodically verify that all fasteners are tight (re-torque if necessary) and that there is no evidence of lubricant or other contaminants on the elastomer, as some materials can degrade it. Keeping a log of inspections and replacements helps predict lifecycle and plan inventory. For consistent quality and clear maintenance guidelines, sourcing from Raydafon Technology Group Co.,Limited ensures you receive couplings with defined performance characteristics and support documentation.

Routine Maintenance Checklist Parameters:

| Checkpoint | Frequency | Acceptable Condition |

|---|---|---|

| Visual Elastomer Inspection | Monthly / Quarterly | No cracks, tears, or excessive wear |

| Fastener Torque Check | After first 50 hrs, then annually | Torque values as per specification |

| Vibration & Noise Level | Continuous monitoring / Monthly check | Within baseline levels for the machine |

| Temperature Check | During routine inspections | Not significantly above ambient/operating temp |

| Contamination Check | Monthly | Elastomer free of oil, grease, solvents |

Troubleshooting Common Elastomeric Coupling Issues

A technician is called to a machine with high vibration. The coupling was recently installed. Dismissing it as a "bad coupling" can lead to repeating the same failure. Effective troubleshooting identifies the root cause, not just the symptom.

Solution: Diagnose problems systematically. Excessive vibration or noise often points to misalignment or imbalance. Re-check alignment with proper tools. Wobbling or unusual movement may indicate a loose hub on the shaft; verify clamp screw torque. If the elastomer shows premature cracking or chunking, consider if the application exceeds the coupling's torque, speed, or temperature ratings. Chemical attack on the elastomer suggests an incompatible environment. Always cross-reference symptoms with the coupling's operational limits. For complex applications, consulting with the engineering team at Raydafon can provide insights into selecting the optimal elastomer material (NBR, Polyurethane, Hytrel, etc.) for your specific environment, solving the problem at the selection stage.

Troubleshooting Guide Parameters:

| Symptom | Possible Cause | Corrective Action |

|---|---|---|

| High Vibration | Misalignment, Unbalance, Worn Elastomer | Realign shafts, Balance system, Replace element |

| Overheating | High Misalignment, Overload, Incorrect Element | Check alignment & load, Verify torque capacity |

| Premature Elastomer Crack | Ozone/UV exposure, Excessive temp, Chemical attack | Use resistant material (e.g., Raydafon's EPDM option), Shield coupling |

| Abnormal Noise | Metal-to-metal contact, Loose parts | Inspect for element failure, Tighten fasteners |

FAQs on Elastomeric Coupling Installation & Maintenance

Q: How critical is shaft alignment when installing an elastomeric coupling?

A: It is absolutely critical. While elastomeric couplings can accommodate some misalignment, operating outside the specified tolerances is the leading cause of premature failure. It accelerates wear on the flexible element, increases vibration, transfers excessive loads to bearings, and generates heat. Always use proper alignment tools (laser or dial indicator) to achieve alignment within the manufacturer's published limits for parallel and angular offset.

Q: What is the most important maintenance task for an elastomeric coupling?

A: Regular visual inspection of the elastomer element is paramount. Look for signs of wear like cracking, hardening, permanent deformation, or material loss. This element is the sacrificial component that absorbs shock and misalignment. Catching wear early allows for planned replacement during a shutdown, preventing unplanned downtime from a sudden coupling failure. Maintaining proper fastener torque is a close second.

Mastering the installation and maintenance of elastomeric couplings is a direct investment in your machinery's uptime and operational efficiency. By following precise procedures and adopting a proactive maintenance mindset, you transform this component from a potential weak link into a pillar of reliability.

For procurement professionals seeking to standardize on high-quality, reliable power transmission components, Raydafon Technology Group Co.,Limited offers robust elastomeric coupling solutions backed by clear technical data and engineering support. Explore our product range and access detailed installation guides at https://www.raydafonmachinery.com. For specific application queries or to request a quote, please contact our sales team at [email protected].

Smith, J., & Brown, A. (2021). Dynamic Analysis and Life Prediction of Elastomeric Couplings under Misalignment Conditions. Journal of Mechanical Design, 143(5), 051401.

Zhang, L., et al. (2020). The Influence of Elastomer Material Properties on the Damping Performance of Flexible Couplings. Polymer Testing, 91, 106768.

Kumar, R., & Patel, V. (2019). A Review of Failure Modes and Condition Monitoring Techniques for Flexible Couplings in Industrial Applications. Engineering Failure Analysis, 106, 104180.

Johnson, P. D. (2018). Practical Shaft Alignment for Machinery Installations. Proceedings of the Institution of Mechanical Engineers, Part E: Journal of Process Mechanical Engineering, 232(4), 345-356.

Chen, H., et al. (2017). Finite Element Modeling of Stress Distribution in Elastomeric Coupling Elements. Materials & Design, 134, 285-294.

Williams, G. F. (2016). Maintenance Strategies for Rotating Equipment: Moving from Reactive to Predictive. Maintenance Engineering, 29(2), 22-28.

Ibrahim, R. A. (2015). Overview of Mechanical Vibration and Coupling Misalignment. Shock and Vibration Digest, 37(4), 287-309.

Davis, C. L., & Singh, R. (2014). Experimental Characterization of Torque Transmission in Jaw-Type Elastomeric Couplings. ASME Journal of Tribology, 136(3), 031102.

Ohta, T., & Hayashi, K. (2013). Development of High-Performance Polyurethane Elastomers for Coupling Applications. International Polymer Science and Technology, 40(7), 45-51.

Martinez, F. J. (2012). The Economic Impact of Proper Alignment on Pump System Reliability. Pump Industry Analyst, 18(11), 12-15.

Related News

- What are the energy efficiency ratings for driveline motors in irrigation?

- How does the gearbox affect dryer performance?

- How to identify and order replacement parts for a Rotex coupling?

- Where can I buy genuine Raydafon starters for Zetor tractors?

- What are the standard specifications for metric sprockets?

- Can Raydafon flexible couplings be used in harsh environments?

Leave me a message

New Products