- Home

- About Us

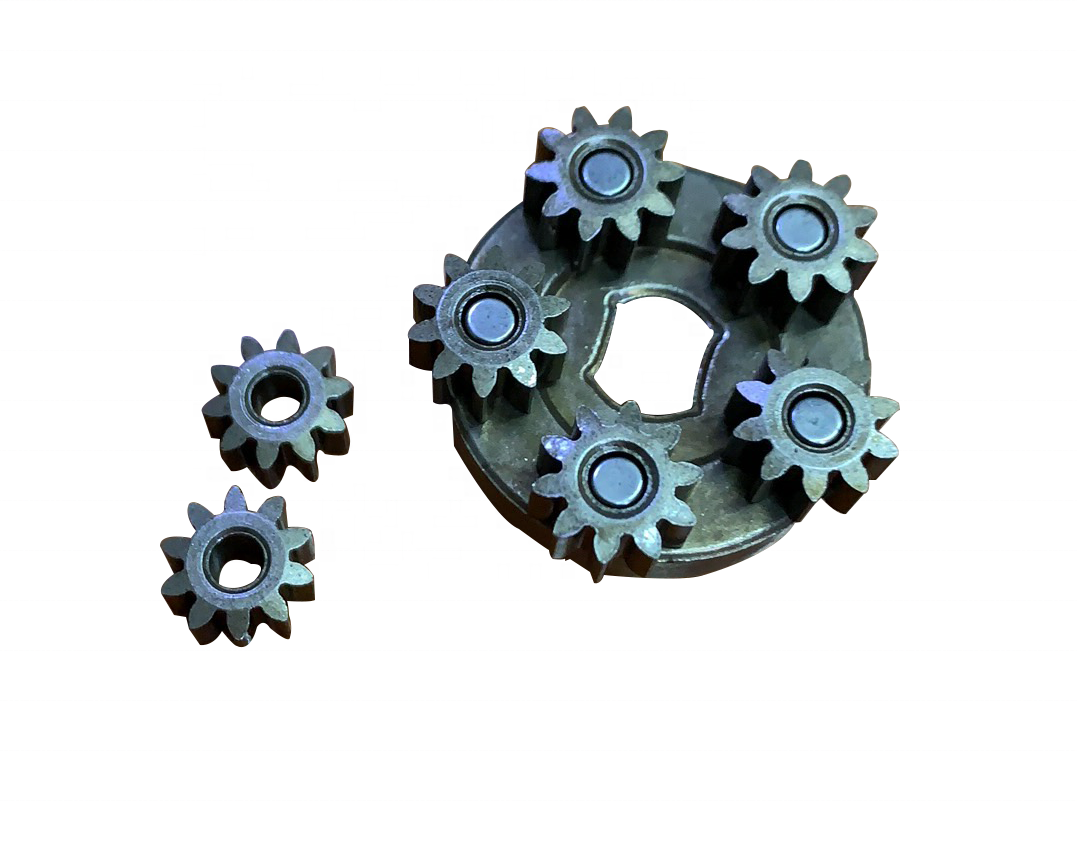

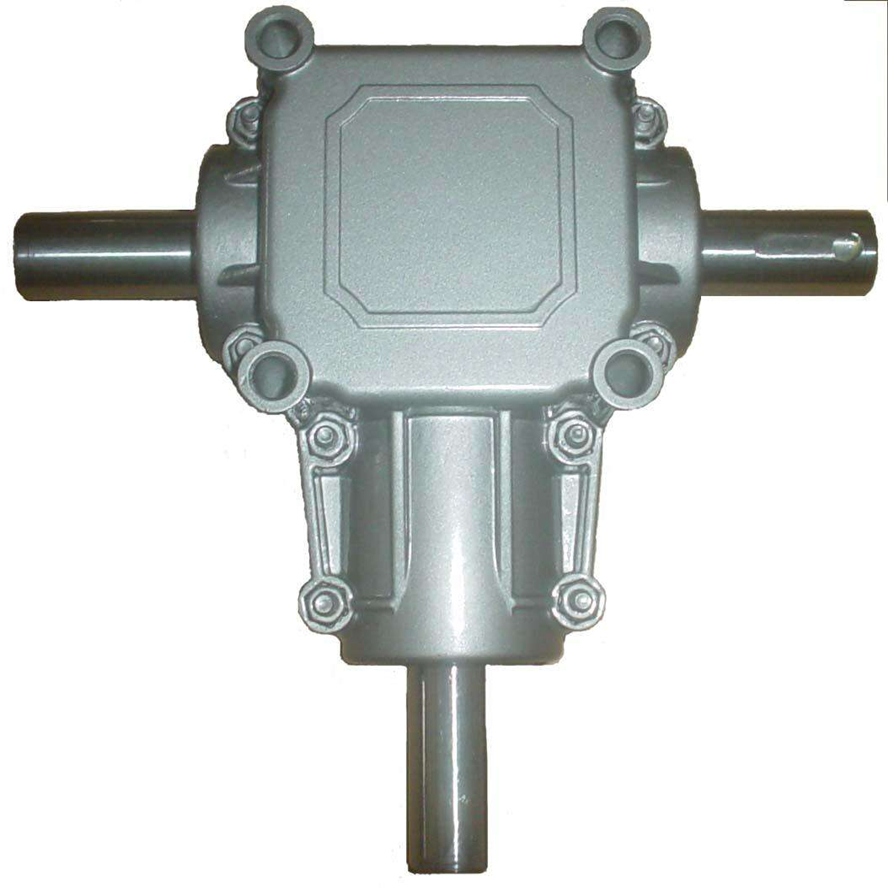

- Products

- Chain

- Sprocket

- Pulley & Sheave

- Gearbox\Reducer

- Belt

- Coupling

- Gear Operator &Valve

- Gear\Rack

- Mechanical seal

- Hub & Bushing

- Hydraulic & Pheumatic

- Shaft Collar

- Locking Assembly

- PTO Shaft

- Mechanical parts

- Conveyor component

- universal joints

- Shaft & York

- vibrator, vibration motor

- Starter & Alternator

- Ungrouped

- Other

- Air Compressor

- News

- Download

- Send Inquiry

- Contact Us

Comparing worm gear vs. planetary gear slewing drives for solar trackers.

Comparing worm gear vs. planetary gear slewing drives for solar trackers. Imagine you're sitting at your desk, tasked with specifying the slewing drives for a massive new solar farm project. The pressure is on to balance upfront cost with long-term reliability and performance. This single component choice can dramatically impact energy yield, maintenance schedules, and overall project ROI. For procurement professionals like you, understanding the fundamental differences between the two dominant drive technologies—worm gear and planetary gear—is crucial. This guide cuts through the complexity, providing you with the clear, actionable insights needed to make a confident, cost-effective decision for your next solar tracking system.

Performance & Durability: The Core Battle

You've approved the site layout. Now, the tracker drives arrive. The project is in a region known for high winds and dust. The primary fear? A drive failing under peak wind load, causing downtime and lost revenue. Worm gear drives offer a natural self-locking feature, providing inherent safety against back-driving in stationary or stow positions, which is a valuable fail-safe. However, their sliding friction results in lower mechanical efficiency (typically 40-70%), generating more heat and requiring more powerful motors. This inefficiency can lead to higher energy consumption over the tracker's lifetime. Planetary gear drives, in contrast, use rolling contact, achieving efficiencies above 90%. This means less heat, smaller motors, and lower operational costs. While they may require an external brake for holding position, their higher torque density and efficiency often make them superior for large, high-performance trackers where maximizing energy capture is paramount. For projects demanding ultimate reliability in harsh, windy environments, the choice becomes clear. Companies like Raydafon Technology Group Co.,Limited specialize in engineering slewing drive solutions that address these precise environmental challenges, offering both worm and planetary configurations tailored to specific site conditions and performance requirements.

| Parameter | Worm Gear Drive | Planetary Gear Drive |

|---|---|---|

| Mechanical Efficiency | 40% - 70% | 90% - 95%+ |

| Back-Driving | Self-locking (Generally) | Requires external brake |

| Torque Density | Moderate | High |

| Heat Generation | Higher | Lower |

| Ideal For | Applications where self-locking is critical, smaller trackers | Large-scale trackers, high-precision tracking, maximizing efficiency |

Total Cost of Ownership & Maintenance Realities

Fast forward 18 months. Your solar farm is operational, but you're reviewing O&M reports. One drive type is showing premature wear, requiring unexpected lubrication and part replacements, eating into the project's profitability. The initial purchase price is only part of the story. Worm gear drives often have a lower upfront cost, which is attractive for tight CAPEX budgets. Yet, their lower efficiency and higher wear rates can lead to increased electricity costs for motors and more frequent maintenance intervals. Planetary gear drives typically command a higher initial investment. However, their high efficiency reduces operational energy costs significantly. Their rolling-element design generally offers longer service life and greater durability under continuous operation, translating to lower long-term maintenance costs and less downtime. When calculating the Levelized Cost of Energy (LCOE), the higher efficiency and reliability of planetary drives often lead to a better lifetime value for utility-scale projects. Raydafon Technology Group Co.,Limited supports procurement teams by providing detailed lifecycle cost analyses, helping to justify capital expenditure with clear data on long-term operational savings and reliability, ensuring your procurement decision aligns with the project's total financial model.

| Cost Factor | Worm Gear Drive | Planetary Gear Drive |

|---|---|---|

| Initial Cost (CAPEX) | Generally Lower | Generally Higher |

| Operational Cost (OPEX) | Higher (due to lower efficiency) | Lower |

| Maintenance Frequency | More Frequent (lubrication, wear checks) | Less Frequent |

| Expected Service Life | Good | Excellent (with proper maintenance) |

| Impact on LCOE | Potentially Higher | Potentially Lower |

Frequently Asked Questions (FAQ)

Q1: When directly comparing worm gear vs. planetary gear slewing drives for solar trackers, which one is more efficient?

A1: Planetary gear slewing drives are significantly more efficient, typically operating at 90-95% efficiency or higher due to their rolling contact design. Worm gear drives operate at 40-70% efficiency because of sliding friction, which generates more heat and requires more input power.

Q2: For a project with very high wind loads, which drive type is safer when comparing worm gear vs. planetary gear slewing drives for solar trackers?

A2: Worm gear drives have a natural self-locking feature that prevents back-driving, offering inherent mechanical safety in stow positions during high winds. Planetary drives require a separate, fail-safe brake system to hold position, adding complexity but not necessarily reducing safety when properly engineered.

We hope this detailed comparison empowers your next procurement decision. Have you encountered specific challenges with drive selection in your projects? What factors weigh most heavily in your evaluations?

For tailored solutions in slewing drive technology, consider Raydafon Technology Group Co.,Limited. With extensive expertise in both worm and planetary gear drives for solar tracking applications, Raydafon provides robust, efficient, and cost-optimized solutions designed to meet the rigorous demands of utility-scale solar farms. Visit https://www.raydafonmachinery.com to explore their product portfolio or contact their engineering team directly at [email protected] for a customized consultation.

1. N. N. Forero, J. D. López, J. R. Pacheco, 2021, "Dynamic modeling and efficiency analysis of slewing drives for solar trackers", Renewable Energy, Vol. 179.

2. K. Lee, S. H. Park, 2020, "A comparative study on the mechanical performance of worm gear and planetary gear reducers under cyclic loading", Mechanism and Machine Theory, Vol. 152.

3. M. Garcia-Sanz, I. Calvo, 2019, "Control strategies for increasing the accuracy of solar trackers with different drive mechanisms", Solar Energy, Vol. 188.

4. A. Fernández, P. M. Rodrigo, 2018, "Reliability and maintenance cost analysis of slewing bearings in photovoltaic plants", Engineering Failure Analysis, Vol. 92.

5. T. Zhang, H. Li, W. Zhao, 2022, "Thermal behavior and efficiency loss in high-torque worm gear drives for renewable energy applications", Applied Thermal Engineering, Vol. 213.

6. J. Müller, B. Schmidt, 2017, "Planetary gearbox design for high-precision solar tracking: optimization of load distribution", Journal of Mechanical Design, Vol. 139(8).

7. R. Santos, F. Almeida, 2021, "Impact of drive train efficiency on the Levelized Cost of Energy (LCOE) in photovoltaic power plants", Energy Reports, Vol. 7.

8. C. Bianchi, L. De Angelis, 2020, "Experimental evaluation of backlash and stiffness in slewing drives for positioning systems", Precision Engineering, Vol. 66.

9. S. Patel, V. Kumar, 2019, "Finite element analysis of contact stresses in worm gear sets used in solar tracker actuators", Materials Today: Proceedings, Vol. 26, Part 2.

10. E. J. Williams, D. R. Clark, 2018, "Long-term field performance and degradation analysis of mechanical components in solar tracking systems", Progress in Photovoltaics: Research and Applications, Vol. 26(11).

Related News

- What is the typical lifespan of a furniture hydraulic cylinder?

- How do I properly install and align an HTD 8M Series timing pulley?

- How do you install and maintain an elastomeric coupling?

- How do trencher chains compare to other trenching methods?

- What is an excavator telescopic rotary hydraulic cylinder and how does it work?

- How to install a John Crane Type 58U mechanical seal?

Leave me a message

New Products