- Home

- About Us

- Products

- Chain

- Sprocket

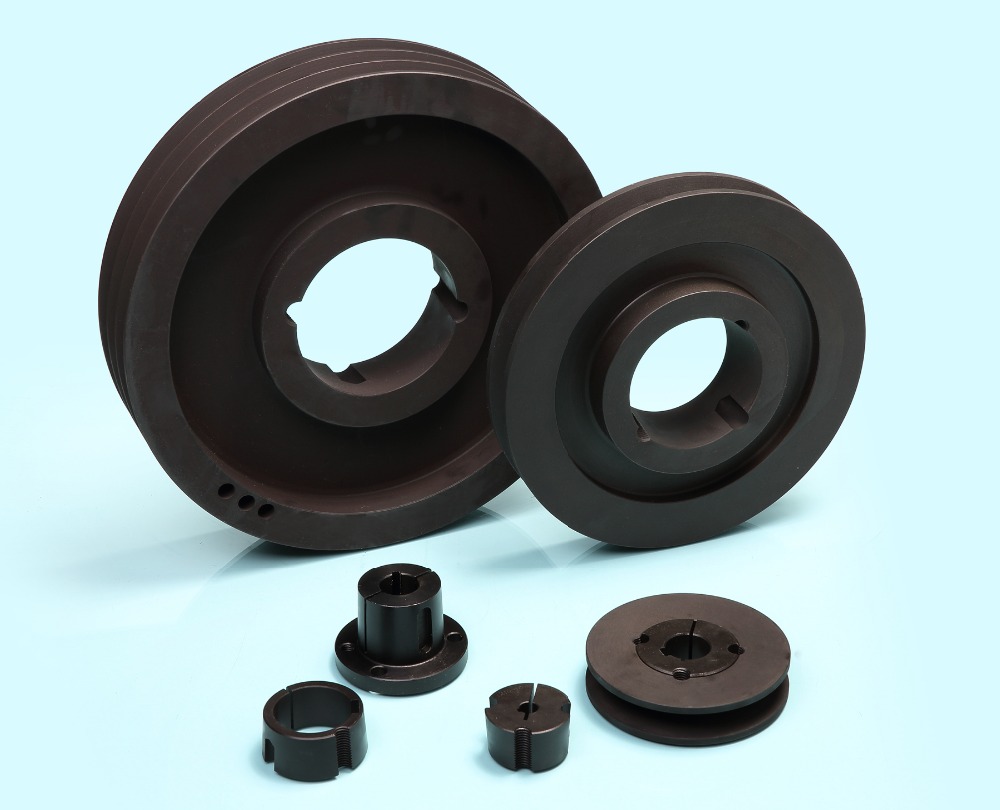

- Pulley & Sheave

- Gearbox\Reducer

- Belt

- Coupling

- Gear Operator &Valve

- Gear\Rack

- Mechanical seal

- Hub & Bushing

- Hydraulic & Pheumatic

- Shaft Collar

- Locking Assembly

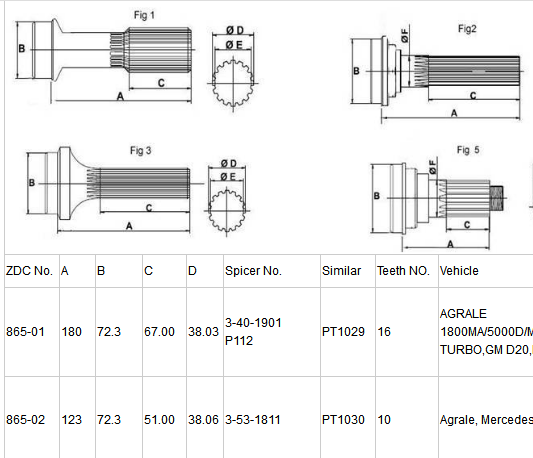

- PTO Shaft

- Mechanical parts

- Conveyor component

- universal joints

- Shaft & York

- vibrator, vibration motor

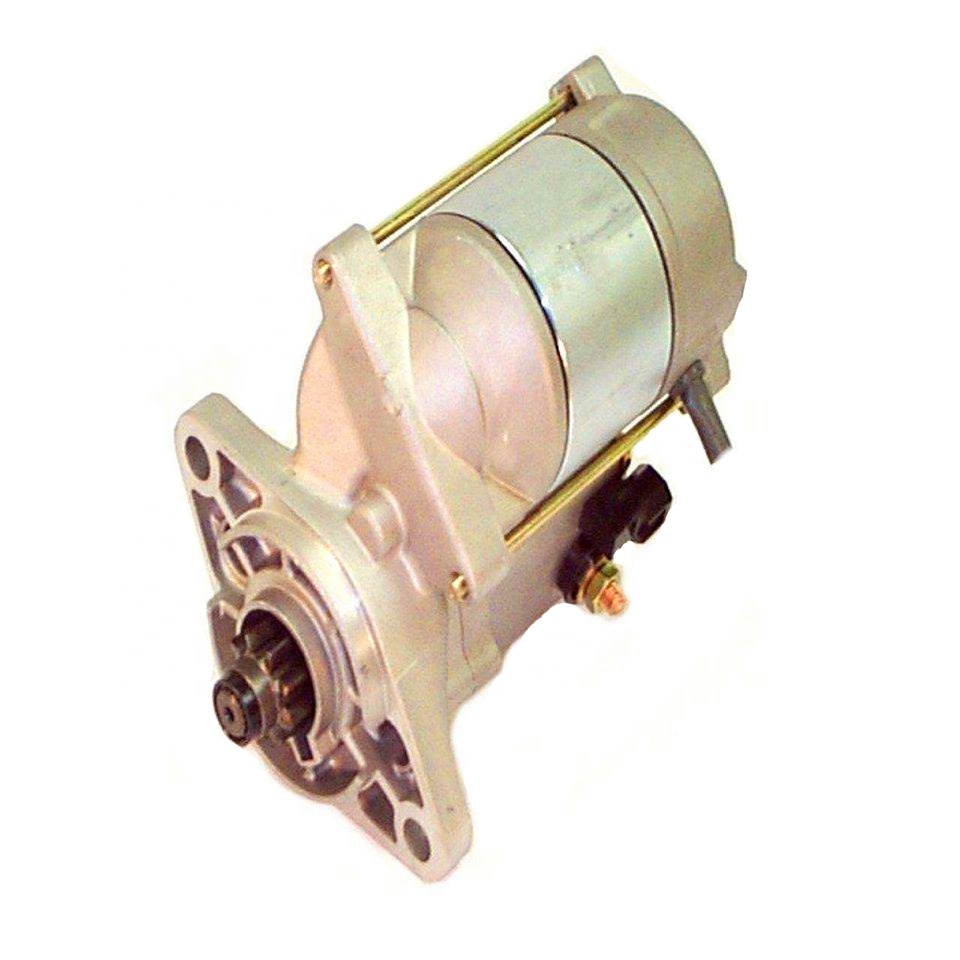

- Starter & Alternator

- Ungrouped

- Other

- Air Compressor

- News

- Download

- Send Inquiry

- Contact Us