- Home

- About Us

- Products

- Chain

- Sprocket

- Pulley & Sheave

- Gearbox\Reducer

- Belt

- Coupling

- Gear Operator &Valve

- Gear\Rack

- Mechanical seal

- Hub & Bushing

- Hydraulic & Pheumatic

- Shaft Collar

- Locking Assembly

- PTO Shaft

- Mechanical parts

- Conveyor component

- universal joints

- Shaft & York

- vibrator, vibration motor

- Starter & Alternator

- Ungrouped

- Other

- Air Compressor

- News

- Download

- Send Inquiry

- Contact Us

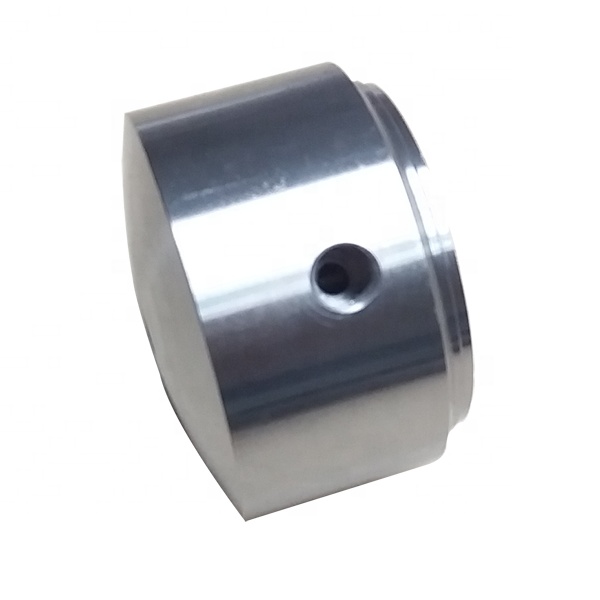

Gear Operator &Valve

Premium Gear Operator & Valve Solutions for Industrial Applications

Gear Operator & Valve systems represent the backbone of efficient fluid control in various industrial processes. Our high-performance solutions are engineered to meet the most demanding operational requirements while ensuring reliability and longevity.

Key Features of Our Gear Operator & Valve Systems

- Precision-engineered gear mechanisms for smooth operation

- Heavy-duty construction materials for extended service life

- Corrosion-resistant coatings for harsh environments

- Standardized mounting interfaces for easy installation

- Low-maintenance design reduces downtime

Technical Specifications

| Model | Size Range | Pressure Rating | Temperature Range | Material |

|---|---|---|---|---|

| GO-100 | 2"-12" | 150-300 PSI | -20°F to 400°F | Ductile Iron |

| GO-200 | 14"-24" | 300-600 PSI | -40°F to 500°F | Carbon Steel |

| GO-300 | 26"-48" | 600-900 PSI | -60°F to 650°F | Stainless Steel |

Gear Operator & Valve FAQ

Q: What maintenance is required for Gear Operator & Valve systems?

A: Our Gear Operator & Valve systems are designed for minimal maintenance. We recommend quarterly visual inspections, annual lubrication of moving parts, and periodic torque checks on mounting hardware. The gear mechanism itself is typically maintenance-free for 5+ years under normal operating conditions.

Q: How do I select the right Gear Operator & Valve for my application?

A: Consider these key factors: 1) Pipe diameter/size, 2) Operating pressure requirements, 3) Temperature range, 4) Fluid medium (water, oil, chemicals), and 5) Frequency of operation. Our technical team can help evaluate your specific needs to recommend the optimal model.

Performance Advantages

- 25% higher torque capacity than industry standards

- Sealed bearing system prevents contamination

- Non-rising stem design for space-constrained installations

- EPDM seats provide bubble-tight shutoff

- OS&Y (Outside Screw and Yoke) design for visual position indication

Common Applications

- Water treatment plants

- Oil and gas pipelines

- Power generation facilities

- Chemical processing plants

- HVAC systems in large commercial buildings

Gear Operator & Valve FAQ (Continued)

Q: What certifications do your Gear Operator & Valve products hold?

A: Our products meet or exceed the following standards: API 6D for pipeline valves, ISO 5211 for mounting interfaces, AWWA C509 for water works applications, and ASME B16.34 for pressure-temperature ratings. All products undergo rigorous testing including hydrostatic, shell, and seat leak tests before shipment.

Installation Guidelines

- Ensure proper alignment between valve and pipeline

- Use appropriate gaskets for the service conditions

- Verify adequate clearance for gear operator rotation

- Follow proper torque specifications during assembly

- Perform operational tests before placing into service

Optional Features

| Option | Description | Benefit |

|---|---|---|

| Electric Actuation | Motorized operation with position feedback | Remote control capability |

| Position Indicators | Visual or electronic position sensing | Improved operational visibility |

| Locking Devices | Tamper-proof security features | Prevents unauthorized operation |

Q: What is the expected service life of your Gear Operator & Valve systems?

A: With proper installation and maintenance, our standard Gear Operator & Valve systems typically achieve 15-20 years of reliable service in normal operating conditions. Critical components like gears and stems are designed for 50,000+ cycles. Harsh environments may reduce lifespan, which is why we offer specialized materials and coatings for extreme conditions.

Technical Support Services

Our team provides comprehensive support including:

- Application engineering assistance

- Installation supervision

- Troubleshooting guides

- Spare parts inventory

- On-site training programs

Gear Operator &Valve