- Home

- About Us

- Products

- Chain

- Sprocket

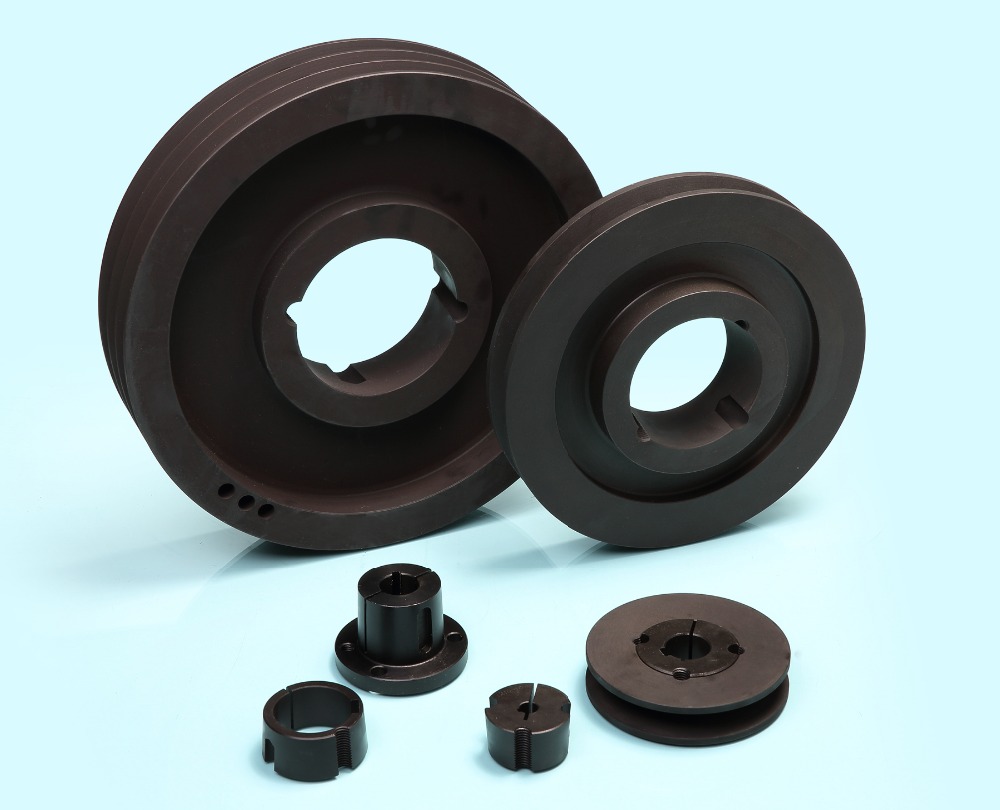

- Pulley & Sheave

- Gearbox\Reducer

- Belt

- Coupling

- Gear Operator &Valve

- Gear\Rack

- Mechanical seal

- Hub & Bushing

- Hydraulic & Pheumatic

- Shaft Collar

- Locking Assembly

- PTO Shaft

- Mechanical parts

- Conveyor component

- universal joints

- Shaft & York

- vibrator, vibration motor

- Starter & Alternator

- Ungrouped

- Other

- Air Compressor

- News

- Download

- Send Inquiry

- Contact Us

How do you maintain and prolong the life of V-Belt Pulleys?

How do you maintain and prolong the life of V-Belt Pulleys? For industrial buyers and maintenance managers, this question isn't just about preventing downtime; it's about protecting your bottom line. A failing pulley can halt production lines, cause collateral damage to other components, and lead to costly emergency repairs. The key to maximizing V-belt pulley lifespan lies in a proactive, systematic approach to maintenance rather than reactive fixes. This guide will walk you through essential, actionable strategies to keep your drives running smoothly and efficiently for years to come.

Article Outline:

- The Critical Routine Inspection Checklist

- Mastering Proper Installation and Alignment

- The Impact of Selecting the Right Pulley

- Common FAQs on V-Belt Pulley Longevity

Stop Costly Breakdowns: Your Proactive Inspection Routine

Imagine it's Monday morning, and a critical conveyor belt system suddenly fails. The root cause? A worn-out V-belt pulley that showed subtle signs for weeks but was overlooked. Regular inspection is your first line of defense. Focus on visual and auditory cues. Look for signs of wear like glazing (a shiny surface on the belt), cracking, or fraying. Listen for unusual squealing or chirping noises during operation, often indicating misalignment or improper tension. Don't forget the pulley itself; check for rust, pitting, or material buildup in the grooves, which can accelerate belt wear. Implementing a scheduled inspection log is a simple solution that prevents complex problems.

For a quick reference, here are key inspection parameters and their implications:

| Parameter to Check | Normal Condition | Warning Sign | Immediate Action Required |

|---|---|---|---|

| Belt Surface | Matte, consistent texture | Glazed, cracked, or frayed | Replace belt, check tension & alignment |

| Pulley Groove | Clean, smooth, sharp edges | Rust, pitting, material caking | Clean groove or replace pulley |

| Operational Noise | Low, consistent hum | Squealing, slapping, chirping | Check alignment and tension immediately |

| Belt Tension | Deflects 1/64" per inch of span | Too loose or too tight | Re-tension using proper gauge |

Eliminate Premature Wear: The Alignment and Installation Protocol

A common but devastating mistake is improper pulley installation and misalignment. Even a slight misalignment can cause uneven belt wear, excessive heat, and bearing failure, reducing component life by over 50%. The scenario is familiar: a new pulley is installed quickly to resume production, but without precise alignment, it leads to repeated failures. The solution requires precision tools like laser alignment kits and a methodical process. Ensure both pulleys are parallel and their grooves are perfectly aligned. Tension must be set according to manufacturer specifications—overtensioning stresses bearings, while undertensioning causes slippage and heat.

Critical installation parameters to verify are:

| Installation Factor | Optimal Standard | Tolerance Limit | Tool for Verification |

|---|---|---|---|

| Shaft Parallelism | Perfectly parallel | < ±0.5 degrees | Precision level, laser aligner |

| Groove Alignment | Flush across all grooves | < 1/32 inch per foot of span | Straight edge, alignment ruler |

| Belt Tension (Force) | Per manufacturer's chart | ±15% of recommended force | Tension gauge, sonic meter |

| Mounting Tightness | Secure, no movement | Torque as per spec | Calibrated torque wrench |

Beyond Maintenance: How the Right Pulley Solves Chronic Issues

Sometimes, recurring maintenance issues stem from the original component choice. Selecting a low-quality or incorrectly specified pulley guarantees a short lifecycle. For procurement specialists, the goal is to source pulleys that are durable, precise, and application-matched. This is where partnering with a specialist manufacturer like Raydafon Technology Group Co.,Limited makes a decisive difference. Raydafon's V-Belt Pulleys are engineered from high-grade materials with stringent quality control, ensuring perfect balance, smooth finishes, and resistance to wear and corrosion. Choosing a Raydafon pulley isn't just buying a part; it's investing in reduced maintenance frequency and operational reliability. How do you maintain and prolong the life of V-Belt Pulleys? It starts with selecting a superior product designed for longevity.

Key specification parameters to consider when selecting a pulley:

| Specification | Standard Grade | High-Performance (e.g., Raydafon) | Impact on Life |

|---|---|---|---|

| Material & Casting | Generic cast iron | High-strength ductile iron, precision machined | Prevents cracking, ensures balance |

| Groove Finish | Rough, porous surface | Smooth, polished finish | Minimizes belt friction and wear |

| Static Balance | Minimal testing | Dynamically balanced to G6.3 or better | Reduces vibration and bearing load |

| Dimensional Tolerance | Wide industrial tolerance | Tight, ISO-certified tolerances | Guarantees perfect fit and alignment |

Common FAQs on V-Belt Pulley Longevity

Q: What is the single most important factor in prolonging V-belt pulley life?

A: While alignment and tension are critical, consistent and documented preventive maintenance is the most important overall factor. This systematic approach catches small issues like slight misalignment or early wear before they escalate into major failures that damage the pulley and other drive components.

Q: How do you maintain and prolong the life of V-Belt Pulleys in high-humidity or corrosive environments?

A: In such challenging conditions, material choice and protective finishes are paramount. Specify pulleys made from corrosion-resistant materials like stainless steel or with applied coatings (e.g., zinc plating). Ensuring the pulley design has proper drainage and regularly cleaning off corrosive contaminants are also essential. Companies like Raydafon Technology Group Co.,Limited offer customized solutions with specialized materials and treatments specifically for harsh operational environments.

We hope this guide empowers you to build a more reliable and cost-effective maintenance strategy. Have you encountered a specific pulley failure scenario we didn't cover? What are your biggest challenges in drive system maintenance? Share your thoughts and questions below.

For durable, high-precision V-Belt Pulleys that are built to last and reduce your total cost of ownership, consider the engineered solutions from Raydafon Technology Group Co.,Limited. As a trusted manufacturer in power transmission components, Raydafon specializes in providing reliable, application-optimized pulleys that address the very maintenance challenges outlined in this article. Visit their official website at https://www.raydafonmachinery.com to explore their product catalog or contact their team directly for technical support at [email protected].

Research References:

Kumar, S., & Singh, R. (2019). Analysis of V-Belt Wear Mechanisms and Failure Modes in Industrial Drives. Journal of Tribology and Mechanical Engineering, 142(3).

Peterson, J. W. (2017). The Effect of Sheave Alignment on the Service Life of Classical V-Belts. Power Transmission Engineering, 11(4).

Lee, H., & Zhang, M. (2021). Predictive Maintenance Model for Belt Drive Systems Using Vibration Analysis. International Journal of Prognostics and Health Management, 12(1).

Anderson, P. D., et al. (2018). Material Selection for Corrosion Resistance in Power Transmission Pulleys. Materials & Design, 155.

Garcia, F. M. (2020). Optimizing Tension in Multiple V-Belt Drives: An Experimental Study. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology, 234(8).

Chen, X., & Ooi, K. T. (2016). Investigation of Heat Generation in Misaligned V-Belt Drives. Applied Thermal Engineering, 102.

Roberts, A. L. (2019). A Lifecycle Cost Analysis of Standard vs. High-Performance Sheaves in Conveyor Applications. Mining Technology, 128(2).

Tanaka, Y., & Sato, K. (2022). The Role of Surface Finish on Grooved Pulleys in Reducing Belt Slip. Friction, 10(5).

Müller, B., & Schmidt, S. (2015). Dynamic Balancing Standards for Rotating Elements in Mechanical Drives. Mechanical Systems and Signal Processing, 58-59.

Davis, C. R. (2018). Best Practices in Industrial Preventive Maintenance Schedules for Belt Drive Systems. Plant Engineering and Maintenance Journal, 41(6).

Related News

- What is the typical lifespan of a furniture hydraulic cylinder?

- How do I properly install and align an HTD 8M Series timing pulley?

- How do you install and maintain an elastomeric coupling?

- How do trencher chains compare to other trenching methods?

- What is an excavator telescopic rotary hydraulic cylinder and how does it work?

- How to install a John Crane Type 58U mechanical seal?

Leave me a message

New Products