- Home

- About Us

- Products

- Chain

- Sprocket

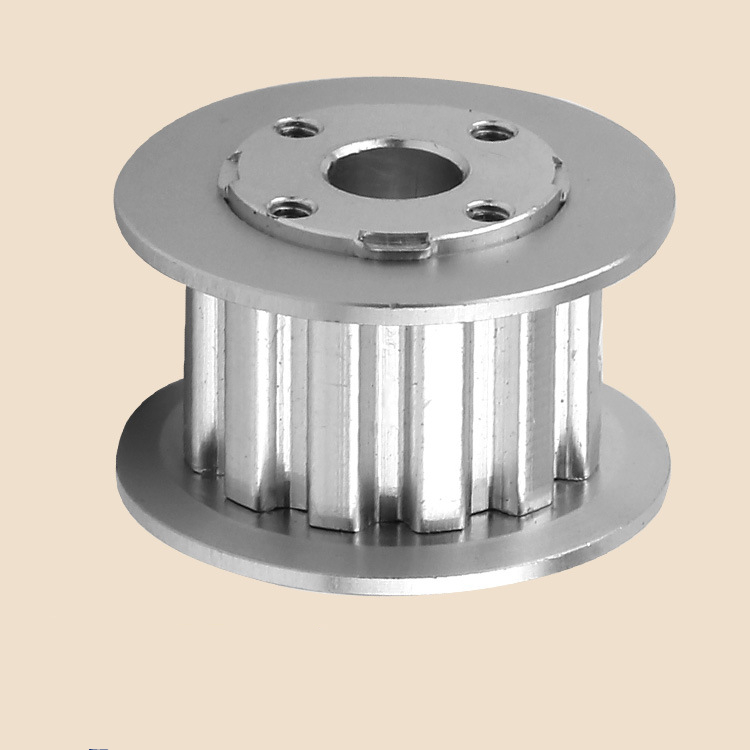

- Pulley & Sheave

- Gearbox\Reducer

- Belt

- Coupling

- Gear Operator &Valve

- Gear\Rack

- Mechanical seal

- Hub & Bushing

- Hydraulic & Pheumatic

- Shaft Collar

- Locking Assembly

- PTO Shaft

- Mechanical parts

- Conveyor component

- universal joints

- Shaft & York

- vibrator, vibration motor

- Starter & Alternator

- Ungrouped

- Other

- Air Compressor

- News

- Download

- Send Inquiry

- Contact Us

Sheave

Sheave products are essential components in various industrial applications, providing reliable performance for lifting, rigging, and mechanical power transmission systems. Our high-quality sheaves are designed to meet the toughest demands while ensuring smooth operation and extended service life.

Sheave Product Specifications

Our sheave products offer superior performance with these key features:

- Material: High-grade alloy steel or stainless steel options

- Surface Treatment: Zinc plating, galvanization, or powder coating

- Bearing Type: Precision ball bearings or bronze bushings

- Working Load Limit: From 0.5 tons to 50 tons capacity

- Temperature Range: -40°F to 400°F (-40°C to 204°C)

- Rope Compatibility: Designed for wire rope, synthetic rope, or cable

Detailed Sheave Technical Parameters

| Model | Diameter (inches) | Groove Type | Max Load (lbs) | Weight (lbs) |

|---|---|---|---|---|

| SHE-100 | 4 | V-Groove | 2,000 | 3.5 |

| SHE-200 | 6 | U-Groove | 4,500 | 7.2 |

| SHE-300 | 8 | Flat-Groove | 8,000 | 12.8 |

| SHE-400 | 10 | Double-Groove | 12,000 | 18.5 |

Sheave FAQ Section

Q: What is the recommended maintenance schedule for sheaves?

A: Sheaves should be inspected monthly for wear and damage. Lubricate bearings every 3 months or after 500 operating hours. Complete disassembly and thorough inspection should be performed annually or after 2,000 operating hours.

Q: How do I select the correct sheave size for my application?

A: The sheave diameter should be at least 20 times the diameter of the wire rope for optimal performance and rope life. Consider the working load limit, rope type, and environmental conditions when selecting your sheave.

Sheave Performance Comparison

| Feature | Standard Sheave | Premium Sheave |

|---|---|---|

| Material | Carbon Steel | Alloy Steel/Stainless Steel |

| Bearing Type | Bronze Bushings | Sealed Ball Bearings |

| Corrosion Resistance | Basic | High (Galvanized/Stainless) |

| Service Life | 2-3 years | 5-7 years |

Proper Sheave Installation Guidelines

- Verify the sheave is compatible with your rope/cable size

- Ensure proper alignment with other system components

- Use appropriate mounting hardware with correct torque specifications

- Check for smooth rotation before applying load

- Perform initial load test at 25% of working load limit

Sheave FAQ Section

Q: What are the signs that a sheave needs replacement?

A: Common indicators include visible cracks or chips, excessive groove wear (more than 10% of rope diameter), bearing play exceeding manufacturer specifications, or any deformation that affects rope alignment.

Q: Can sheaves be used with both wire rope and synthetic rope?

A: While some sheaves are designed for dual-purpose use, we recommend using specific sheaves designed for each rope type. Wire rope sheaves typically have deeper grooves, while synthetic rope sheaves often feature smoother surfaces to prevent fiber damage.

Sheave Safety Considerations

- Never exceed the working load limit

- Inspect for wear patterns that indicate misalignment

- Replace sheaves in matched sets when multiple sheaves are used together

- Protect sheaves from impact damage during handling and installation

- Use proper personal protective equipment when installing or maintaining sheaves

Sheave FAQ Section

Q: How does sheave material affect performance in different environments?

A: Carbon steel sheaves work well in standard conditions but may corrode in wet or chemical environments. Stainless steel offers superior corrosion resistance for marine or chemical applications. Alloy steel provides the best strength-to-weight ratio for heavy-duty applications.

Q: What is the advantage of using sheaves with sealed bearings?

A: Sealed bearings prevent contamination from dirt, dust, and moisture, significantly extending service life and reducing maintenance requirements. They're particularly beneficial in harsh environments where frequent relubrication would be difficult.

Sheave Applications

| Industry | Application | Recommended Sheave Type |

|---|---|---|

| Construction | Crane Systems | Heavy-duty alloy steel with sealed bearings |

| Marine | Rigging and Sail Systems | Stainless steel with corrosion-resistant coatings |

| Mining | Hoisting Equipment | Extra-heavy-duty with wear-resistant grooves |

| Manufacturing | Conveyor Systems | Precision-balanced for smooth operation |

Sheave