- Home

- About Us

- Products

- Chain

- Sprocket

- Pulley & Sheave

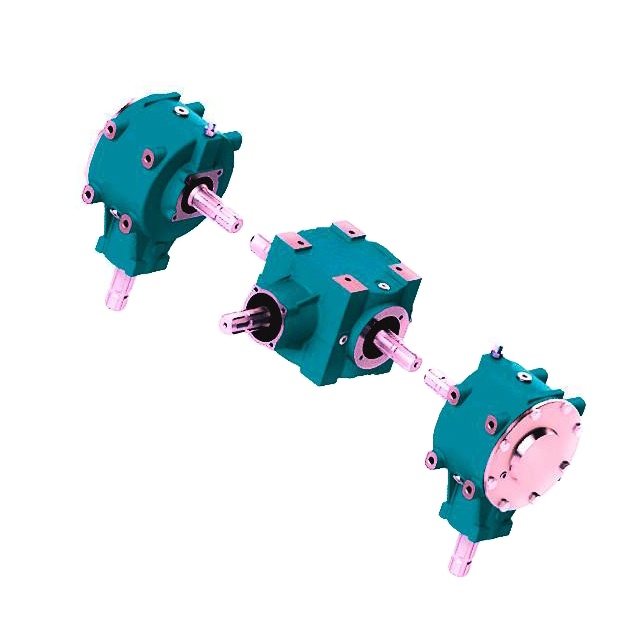

- Gearbox\Reducer

- Belt

- Coupling

- Gear Operator &Valve

- Gear\Rack

- Mechanical seal

- Hub & Bushing

- Hydraulic & Pheumatic

- Shaft Collar

- Locking Assembly

- PTO Shaft

- Mechanical parts

- Conveyor component

- universal joints

- Shaft & York

- vibrator, vibration motor

- Starter & Alternator

- Ungrouped

- Other

- Air Compressor

- News

- Download

- Send Inquiry

- Contact Us

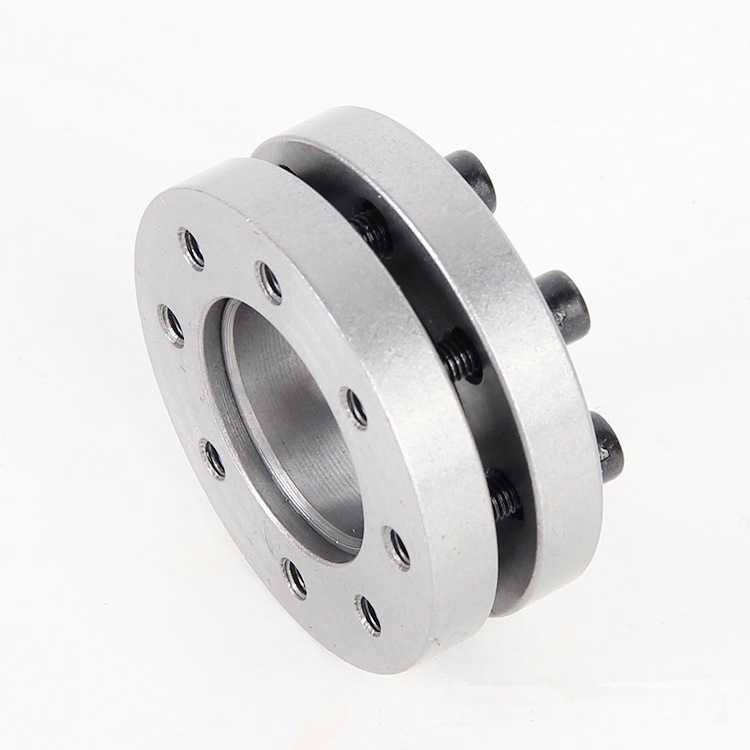

Locking Assembly

Locking Assembly: The Ultimate Solution for Secure Power Transmission

Locking Assembly is a critical component in mechanical power transmission systems, providing a secure and vibration-resistant connection between shafts and hubs. Our premium Locking Assembly products are engineered to deliver exceptional performance in demanding industrial applications.

Key Features of Our Locking Assembly

- High torque transmission capacity

- Precision-engineered components

- Corrosion-resistant materials

- Easy installation and removal

- Maintenance-free operation

- Wide range of sizes available

Technical Specifications

| Model | Bore Range (mm) | Max Torque (Nm) | Max Speed (rpm) | Material |

|---|---|---|---|---|

| LA-100 | 10-25 | 150 | 5000 | Stainless Steel |

| LA-200 | 25-50 | 500 | 4000 | Alloy Steel |

| LA-300 | 50-100 | 1200 | 3000 | Carbon Steel |

| LA-400 | 100-200 | 3000 | 2000 | Hardened Steel |

Advantages of Choosing Our Locking Assembly

Our Locking Assembly offers superior performance compared to traditional keyed connections or splines. The unique design eliminates the need for additional fastening elements while maintaining high positional accuracy. The tapered clamping principle ensures uniform force distribution across the entire contact area.

Locking Assembly FAQ

What is the maximum temperature range for Locking Assembly operation?

Our standard Locking Assembly models can operate within -30°C to +120°C. For extreme temperature applications, we offer special heat-resistant versions capable of withstanding up to 250°C.

How often should Locking Assembly be inspected?

We recommend visual inspection every 3-6 months depending on operating conditions. No routine maintenance is required under normal circumstances, but periodic checks ensure optimal performance in critical applications.

Can Locking Assembly be used for reversing rotation applications?

Yes, our Locking Assembly is designed to handle bidirectional torque transmission equally effectively. The symmetrical design ensures consistent performance regardless of rotation direction.

Installation Guidelines

- Clean both shaft and hub contact surfaces thoroughly

- Apply recommended lubricant to tapered surfaces

- Position Locking Assembly onto shaft

- Slide hub into position

- Tighten screws in cross pattern to specified torque

- Verify proper engagement and alignment

Applications

Locking Assembly is widely used in various industries including:

- Pump and compressor drives

- Conveyor systems

- Gearboxes and reducers

- Machine tool spindles

- Mining equipment

- Marine propulsion systems

Material Specifications

All our Locking Assembly products undergo rigorous material testing to ensure:

- Tensile strength exceeding 800 MPa

- Surface hardness of 58-62 HRC

- Corrosion resistance meeting ISO 9227 standards

- Precision machining within 0.01mm tolerance

Customization Options

We offer specialized Locking Assembly solutions including:

- Explosion-proof designs for hazardous environments

- Food-grade versions with FDA-approved materials

- High-speed variants for turbine applications

- Custom bore sizes and shapes

- Special surface treatments for enhanced performance

Locking Assembly