- Home

- About Us

- Products

- Chain

- Sprocket

- Pulley & Sheave

- Gearbox\Reducer

- Belt

- Coupling

- Gear Operator &Valve

- Gear\Rack

- Mechanical seal

- Hub & Bushing

- Hydraulic & Pheumatic

- Shaft Collar

- Locking Assembly

- PTO Shaft

- Mechanical parts

- Conveyor component

- universal joints

- Shaft & York

- vibrator, vibration motor

- Starter & Alternator

- Ungrouped

- Other

- Air Compressor

- News

- Download

- Send Inquiry

- Contact Us

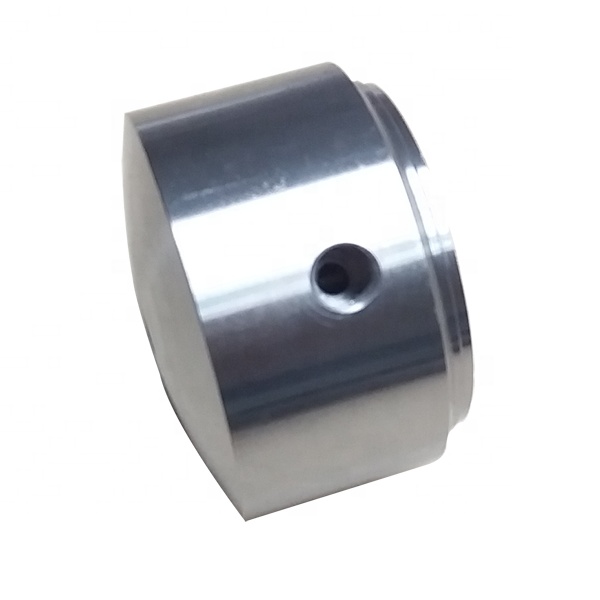

Japan Standard Sprockets

Japan Standard Sprockets: Precision Engineered for Superior Performance

For industrial machinery, automotive applications, and power transmission systems, Japan Standard Sprockets stand as the benchmark for quality and reliability. Manufactured to exacting Japanese industrial standards (JIS), these sprockets ensure seamless operation in demanding environments.

Key Features of Japan Standard Sprockets

- Material: High-grade carbon steel (S45C) or stainless steel (SUS304)

- Hardness: HRC 50-55 (heat treated for enhanced durability)

- Precision: Ground teeth with ±0.01mm tolerance

- Surface Treatment: Black oxide or zinc plating (corrosion resistance)

- Temperature Range: -30°C to 120°C continuous operation

Technical Specifications

| Type | Pitch (mm) | Number of Teeth | Bore Size (mm) | Max RPM |

|---|---|---|---|---|

| JIS B 1801 | 6.35 - 50.8 | 10-120 | 10-100 | 3000 |

| JIS B 1802 | 8.00 - 50.8 | 12-80 | 12-90 | 2800 |

| JIS B 1803 | 9.525 - 76.2 | 15-60 | 15-110 | 2500 |

Japan Standard Sprockets FAQ

What makes Japan Standard Sprockets different from other standards?

Japan Standard Sprockets adhere to strict JIS specifications that mandate tighter tolerances, superior material quality, and more rigorous testing than ISO or ANSI standards. The teeth profile is optimized for smoother chain engagement and reduced noise, while the hardened surfaces provide 30-40% longer service life compared to standard industrial sprockets.

How do I select the right Japan Standard Sprocket for my application?

For Japan Standard Sprockets, you must consider: 1) Chain pitch size (measured between link pins), 2) Required number of teeth (affecting speed ratio), 3) Bore diameter (must match your shaft size), and 4) Hub configuration (type A, B, or C for different mounting needs). Always consult JIS B 1801-1803 specifications and verify compatibility with your existing chain system.

What maintenance do Japan Standard Sprockets require?

Japan Standard Sprockets are designed for minimal maintenance but we recommend: Monthly visual inspections for tooth wear (replace if 10% of tooth height is worn), quarterly lubrication (use JIS Z 2220 specified grease), and annual alignment checks. Unlike conventional sprockets, Japan Standard versions feature special oil-retention grooves that extend lubrication intervals by 50%.

Performance Comparison Table

| Parameter | Japan Standard | ANSI Standard | ISO Standard |

|---|---|---|---|

| Tooth Hardness | HRC 50-55 | HRC 45-50 | HRC 40-48 |

| Maximum RPM | 3000 | 2500 | 2800 |

| Precision Tolerance | ±0.01mm | ±0.03mm | ±0.02mm |

| Average Lifespan | 10,000 hrs | 7,500 hrs | 8,000 hrs |

Japan Standard Sprockets Installation Guide

- Verify sprocket markings match JIS specifications

- Clean shaft and sprocket bore with industrial solvent

- Align sprockets within 0.5mm parallel offset

- Use proper mounting tools (JIS impact grade bolts)

- Torque fasteners to specified JIS B 1082 values

- Conduct test run at 50% load for 2 hours

Advanced Applications of Japan Standard Sprockets

Beyond conventional uses, Japan Standard Sprockets excel in:

- High-speed automation lines (robotics, packaging)

- Precision timing systems (medical equipment)

- Heavy-duty mining conveyors

- Marine propulsion systems

Japan Standard Sprockets FAQ (Continued)

Can Japan Standard Sprockets work with ANSI chains?

While Japan Standard Sprockets can physically engage with ANSI chains, we strongly advise against mixing standards. The different tooth profiles cause accelerated wear (up to 3x faster) and reduce efficiency by 15-20%. For optimal performance, always pair Japan Standard Sprockets with JIS-compliant chains.

What's the lead time for custom Japan Standard Sprockets?

Standard Japan Standard Sprockets ship within 3-5 business days. Custom configurations (special materials, teeth counts, or bore sizes) require 2-3 weeks manufacturing time plus JIS certification. Expedited services are available for urgent requirements with 40% surcharge.

How are Japan Standard Sprockets tested for quality?

Every Japan Standard Sprocket undergoes: 1) Dimensional verification with coordinate measuring machines, 2) Hardness testing at 3 surface points, 3) Dynamic balance testing at 1.5x rated RPM, and 4) Salt spray testing for corrosion resistance. Batch samples receive additional fatigue testing (minimum 1 million cycles).

Dimensional Standards Reference

| JIS Standard | Chain Type | Roller Diameter Tolerance | Pitch Accumulation Error |

|---|---|---|---|

| JIS B 1801 | RS Roller Chain | ±0.05mm | ≤0.15% |

| JIS B 1802 | Heavy Duty Chain | ±0.08mm | ≤0.20% |

| JIS B 1803 | Double Pitch Chain | ±0.10mm | ≤0.25% |

Japan Standard Sprockets