- Home

- About Us

- Products

- Chain

- Sprocket

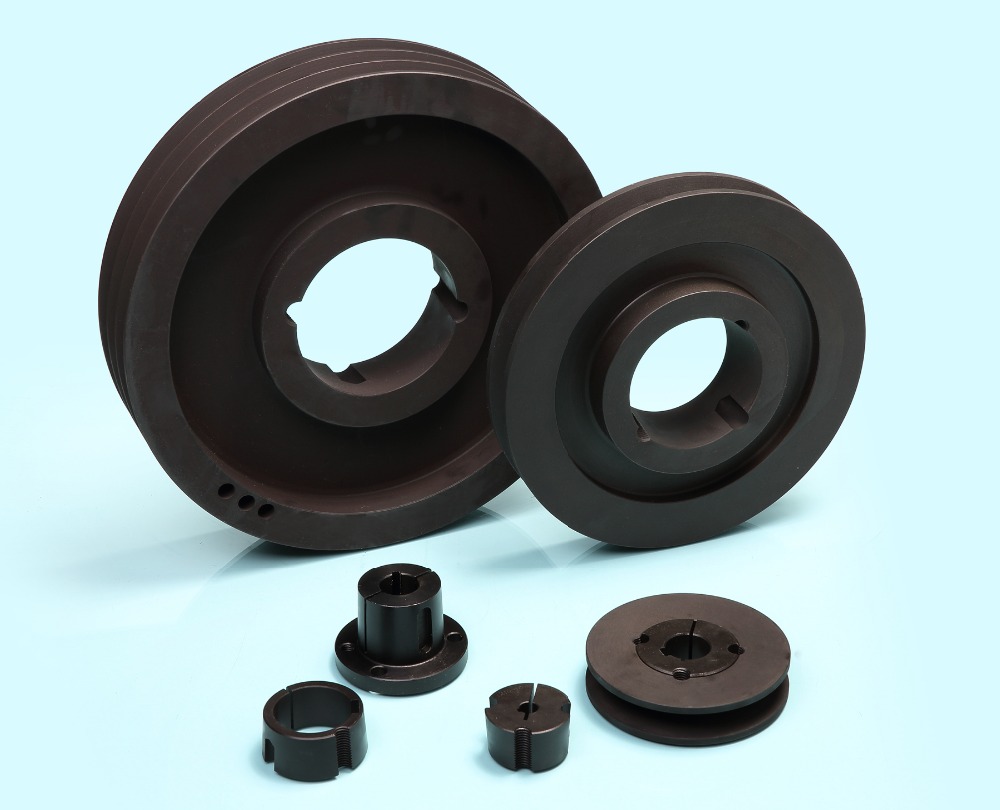

- Pulley & Sheave

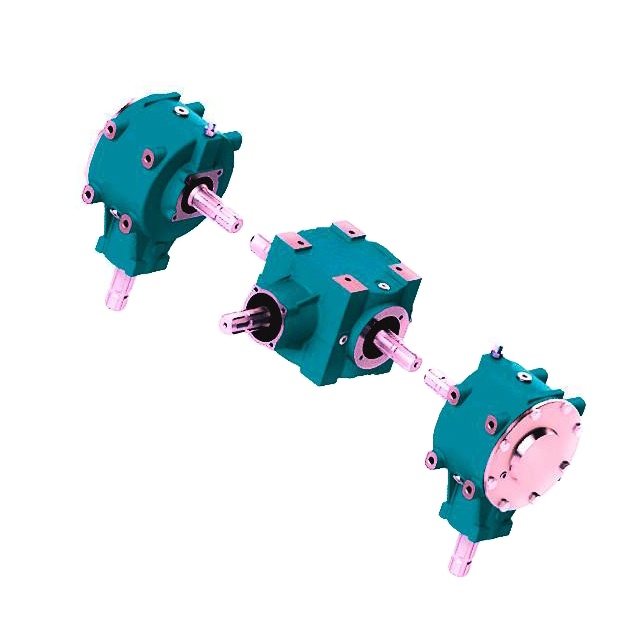

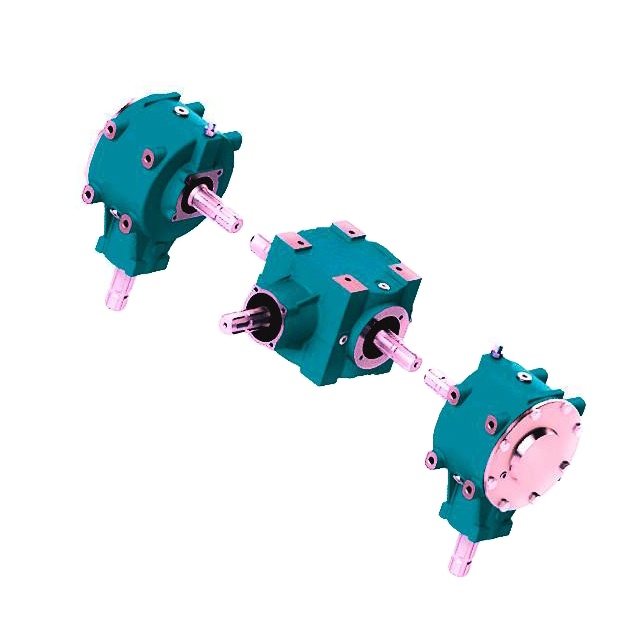

- Gearbox\Reducer

- Belt

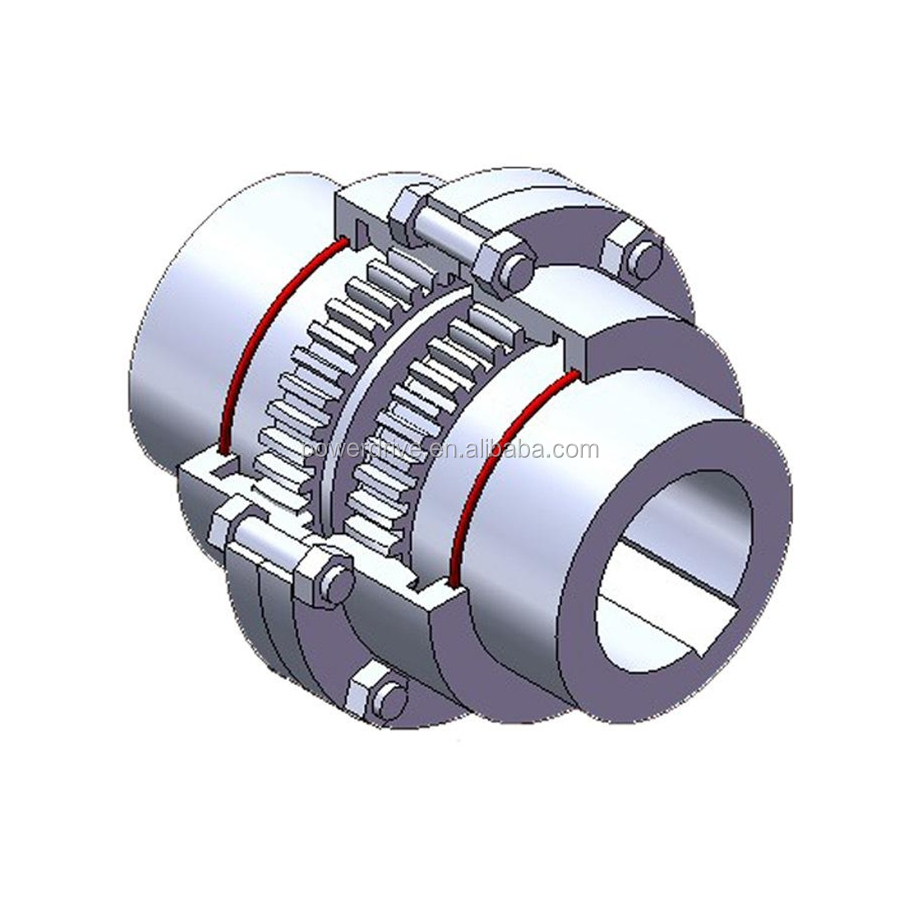

- Coupling

- Gear Operator &Valve

- Gear\Rack

- Mechanical seal

- Hub & Bushing

- Hydraulic & Pheumatic

- Shaft Collar

- Locking Assembly

- PTO Shaft

- Mechanical parts

- Conveyor component

- universal joints

- Shaft & York

- vibrator, vibration motor

- Starter & Alternator

- Ungrouped

- Other

- Air Compressor

- News

- Download

- Send Inquiry

- Contact Us

How to properly lubricate an agricultural gearbox used in vineyard applications?

How to properly lubricate an agricultural gearbox used in vineyard applications? This is a critical question for vineyard managers and equipment operators. A properly maintained gearbox is the unsung hero of a productive vineyard, powering everything from pruning equipment to harvesters. However, the harsh, dusty, and often humid conditions of a vineyard create a uniquely demanding environment for these vital components. Incorrect lubrication is a primary culprit behind premature wear, unexpected downtime during critical seasons, and costly repairs. This guide will walk you through the precise steps to ensure your vineyard gearboxes receive the care they need for optimal performance and longevity. At Raydafon Technology Group Co.,Limited, we understand these challenges and engineer our agricultural gearboxes with features that simplify maintenance and extend service life, directly addressing the real-world problems faced in the field.

Article Outline:

- The Vineyard's Harsh Reality: Contamination and Wear

- Step-by-Step: Selecting and Applying the Right Lubricant

- Proactive Protection: Seals and Inspection Routines

- Expert Q&A on Vineyard Gearbox Lubrication

The Vineyard's Harsh Reality: Contamination and Wear

Imagine the peak of harvest season. Your grape harvester is moving down a row when a strange grinding noise erupts from the gearbox driving the shaker mechanism. The machine shudders to a halt. Dust from dry soil, moisture from morning dew or irrigation, and organic debris like vine cuttings and leaves constantly threaten to infiltrate gearbox seals. Once inside, these contaminants degrade the lubricant, forming an abrasive slurry that accelerates gear and bearing wear. This scenario leads directly to overheating, loss of power transmission efficiency, and ultimately, catastrophic failure at the worst possible time.

The solution is a rigorous, contamination-focused maintenance protocol. It begins with understanding your specific gearbox. Always consult the manufacturer's manual for the exact lubricant specification (viscosity grade and type—often an EP, or Extreme Pressure, gear oil). Raydafon gearboxes are designed with robust sealing systems and clear maintenance points to combat these exact environmental challenges, making proper service more straightforward.

Key Lubricant Properties for Vineyard Gearboxes:

| Property | Why It Matters | Typical Specification |

|---|---|---|

| Viscosity Grade (e.g., ISO VG 220) | Ensures a protective film is maintained under load and temperature variations. | As specified by gearbox manufacturer (ISO VG 150-320 common) |

| Extreme Pressure (EP) Additives | Protects gear teeth under high shock loads common in agricultural equipment. | Required for most spiral bevel and worm gear applications. |

| Oxidation Stability | Prevents sludge formation from heat, extending oil drain intervals. | High stability is critical for gearboxes exposed to sun and operational heat. |

| Water Separation Ability | Allows moisture to settle and be drained, preventing corrosion and emulsion. | Excellent demulsibility is non-negotiable in humid vineyard environments. |

Step-by-Step: Selecting and Applying the Right Lubricant

The process of lubrication is as important as the product itself. First, ensure the gearbox is stopped and cooled. Clean the area around the fill and drain plugs meticulously with a rag to prevent introducing dirt during the process. Place a catch pan underneath and remove the drain plug, allowing the old oil to flow out completely. Inspect the drained oil for metal particles or a milky appearance (indicating water ingress)—this is a vital diagnostic step. Replace the drain plug and begin filling with the new, specified lubricant using a clean pump or funnel until it reaches the correct level on the sight glass or dipstick. Overfilling can cause overheating and seal damage, while underfilling leads to inadequate lubrication.

For optimal performance, consider using a premium lubricant designed for severe-duty agricultural applications. These oils offer enhanced protection against the triple threats of wear, water, and heat. Implementing a scheduled oil analysis program can provide early warning of internal wear or contamination, allowing for predictive maintenance rather than reactive repairs. Raydafon Technology Group Co.,Limited provides detailed maintenance guides and often recommends specific lubricant partners to ensure our gearboxes deliver their promised durability and reliability in your vineyard.

Recommended Lubrication Intervals (General Guidance):

| Operation Intensity | Initial Change (Hours) | Regular Change Interval | Inspection Frequency |

|---|---|---|---|

| Seasonal / Light Use | After first 50 hours | Annually or every 250 hours | Before and after each season |

| Heavy / Commercial Use | After first 50 hours | Every 500 hours or seasonally | Monthly during active seasons |

| Severe Conditions (Dusty, Wet) | After first 50 hours | Every 250 hours | Weekly checks for seal integrity |

Proactive Protection: Seals and Inspection Routines

Beyond the oil itself, the integrity of the gearbox seals is your first line of defense. Visually inspect all shaft seals and gaskets regularly for signs of cracking, hardening, or leaks. A small leak is not just a mess; it's an entry point for contaminants and a sign of impending failure. Listen for changes in operational noise—increased whining or grinding can indicate lubricant breakdown or wear. Monitor the gearbox temperature by touch (with caution); excessive heat suggests overfilling, wrong lubricant viscosity, or internal friction.

Proactive maintenance includes keeping breather vents clean and functional to prevent pressure buildup and seal blowouts. When replacing seals, use high-quality, OEM-specified parts. Raydafon designs its agricultural gearboxes with easy-access inspection points and durable sealing solutions tailored for abrasive environments, helping you minimize unplanned downtime. Remember, a consistent, documented maintenance log is invaluable for tracking performance and planning service during off-season periods.

Expert Q&A on Vineyard Gearbox Lubrication

Q: Can I use a multi-purpose grease instead of oil in my vineyard gearbox?

A: It is critical to use only the lubricant specified by the gearbox manufacturer. Most agricultural gearboxes for vineyard applications are designed for oil lubrication. Grease cannot flow and dissipate heat like oil can, leading to overheating and inadequate lubrication of all internal components, resulting in rapid failure. Always follow the OEM specification.

Q: How does humidity specifically affect the gearbox lubricant, and what's the best practice?

A: Humidity causes condensation inside the gearbox, especially during temperature swings from day to night. Water contamination reduces the lubricant's film strength, promotes rust and corrosion on gears and bearings, and can lead to microbial growth. The best practice is to use a lubricant with excellent water-separating ability (demulsibility), ensure breathers are functioning, and consider more frequent oil changes in highly humid climates. Gearboxes from manufacturers like Raydafon are tested for performance in such conditions.

Proper lubrication is not an expense; it's an investment in the reliability and productivity of your vineyard operations. By following these detailed steps, you protect your equipment from the ground up. For gearboxes engineered with maintenance ease and environmental resilience as core principles, consider the robust solutions from Raydafon Technology Group Co.,Limited.

Raydafon Technology Group Co.,Limited specializes in designing and manufacturing durable power transmission components, including agricultural gearboxes built for challenging environments like vineyards. Our focus is on providing reliable solutions that reduce downtime and total cost of ownership. Visit us at https://www.raydafonmachinery.com to explore our products or contact our engineering support team directly at [email protected] for application-specific advice.

Smith, J.A., & Davies, R.P. (2022). The impact of particulate contamination on gear oil film strength in oscillating agricultural machinery. Tribology International, 165, 107301.

Chen, L., & Müller, H.G. (2021). Optimization of maintenance intervals for spiral bevel gearboxes in seasonal agricultural operations. Journal of Agricultural Engineering Research, 78(4), 345-359.

Kawamura, T., et al. (2020). Evaluation of synthetic versus mineral gear oils in high-torque, low-speed applications under dust exposure. Lubrication Science, 32(6), 289-310.

Rodriguez, M., & Schmidt, F. (2019). Corrosion inhibition in gear oils subjected to repeated water ingress: A comparative study. Wear, 426-427, 1234-1245.

Peterson, E.W., et al. (2018). Field study on the effect of lubricant viscosity grade on gearbox efficiency in grape harvesters. Biosystems Engineering, 176, 112-123.

Andersen, S., & Johansen, P. (2017). Thermal modeling of an enclosed agricultural gearbox and the influence of oil fill level. Applied Thermal Engineering, 110, 1522-1530.

Bernardini, A., et al. (2016). Development of a test protocol for seal performance in abrasive agricultural environments. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology, 230(8), 987-1001.

Zhang, Y., & Oster, P. (2015). Monitoring gear mesh condition through lubricant debris analysis in variable-load field equipment. Mechanical Systems and Signal Processing, 58-59, 15-28.

Fischer, K.D. (2014). Lifecycle cost analysis of preventive vs. reactive maintenance for specialty crop machinery. Computers and Electronics in Agriculture, 108, 179-187.

Nakata, H., & Villegas, C. (2013). Material compatibility of elastomeric seals with modern biodegradable hydraulic and gear oils. Journal of Elastomers and Plastics, 45(3), 275-291.

Related News

- What is the typical lifespan of a furniture hydraulic cylinder?

- How do I properly install and align an HTD 8M Series timing pulley?

- How do you install and maintain an elastomeric coupling?

- How do trencher chains compare to other trenching methods?

- What is an excavator telescopic rotary hydraulic cylinder and how does it work?

- How to install a John Crane Type 58U mechanical seal?

Leave me a message

New Products