- Home

- About Us

- Products

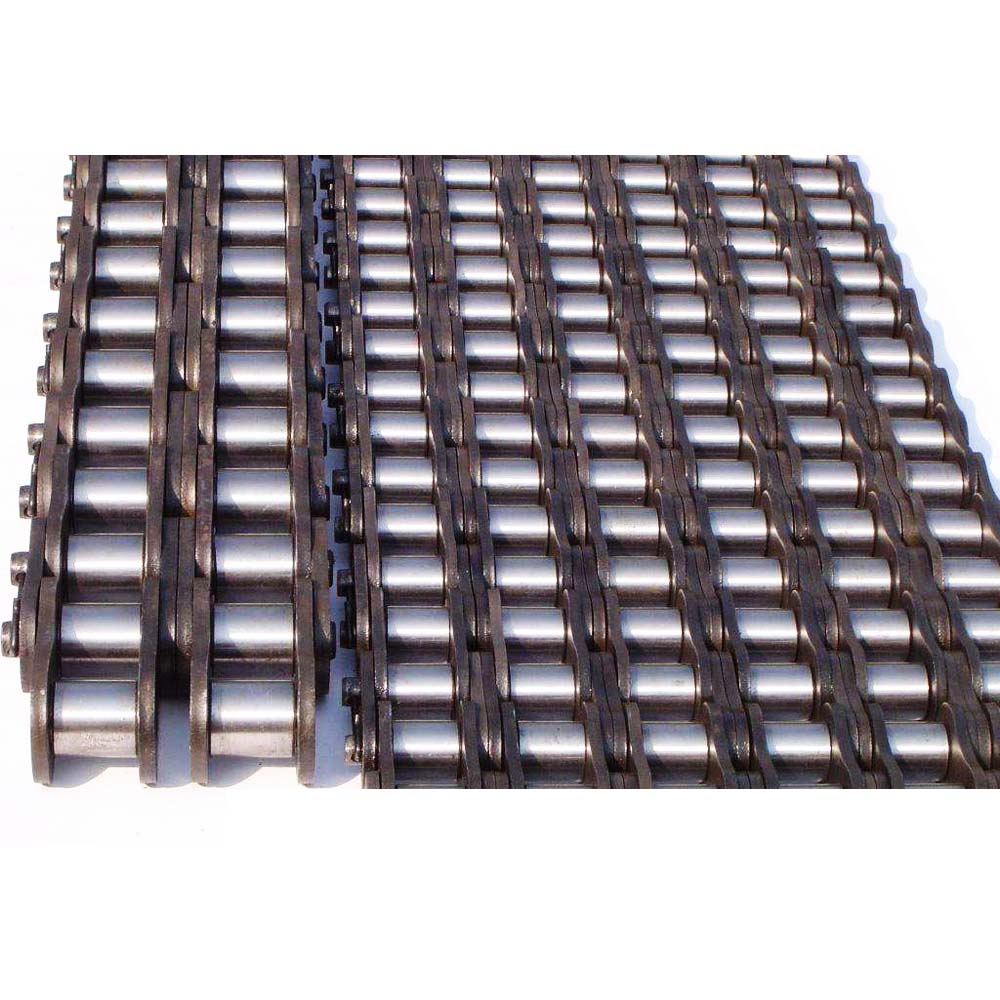

- Chain

- Sprocket

- Pulley & Sheave

- Gearbox\Reducer

- Belt

- Coupling

- Gear Operator &Valve

- Gear\Rack

- Mechanical seal

- Hub & Bushing

- Hydraulic & Pheumatic

- Shaft Collar

- Locking Assembly

- PTO Shaft

- Mechanical parts

- Conveyor component

- universal joints

- Shaft & York

- vibrator, vibration motor

- Starter & Alternator

- Ungrouped

- Other

- Air Compressor

- News

- Download

- Send Inquiry

- Contact Us

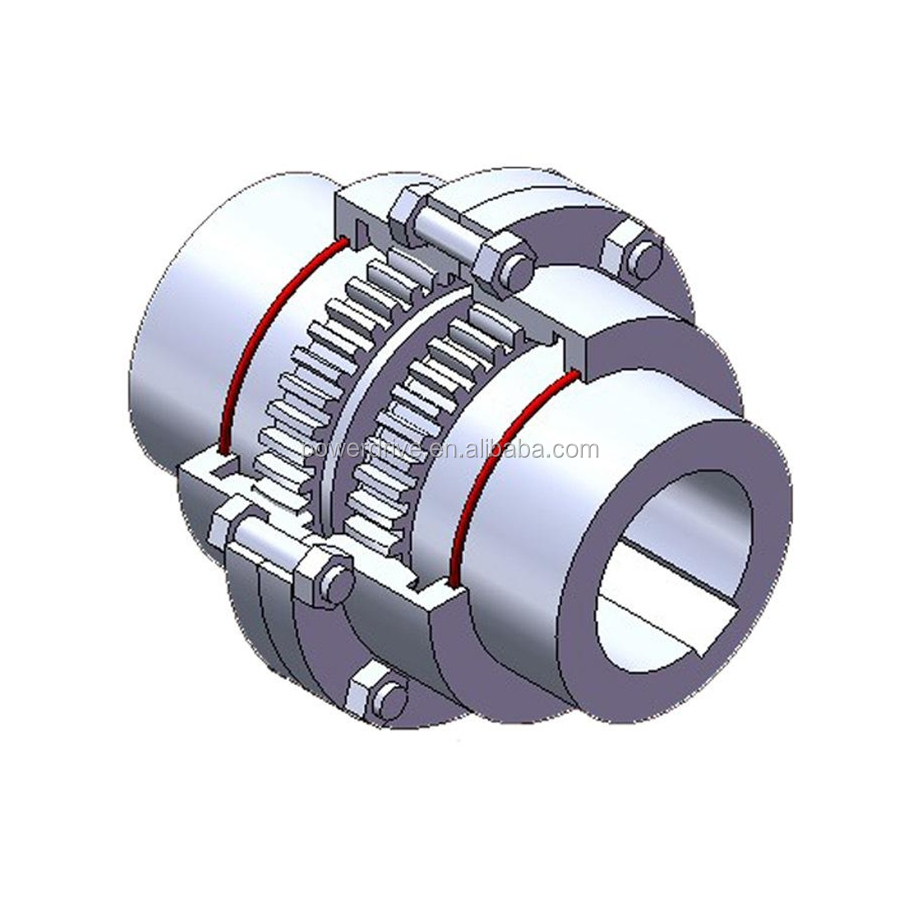

How to install and align GCLD type gear couplings correctly?

How to Install and Align GCLD Type Gear Couplings Correctly: A Step-by-Step Guide

For maintenance engineers and procurement specialists, the question "How to install and align GCLD type gear couplings correctly?" is a critical one. A single misstep during installation can lead to premature wear, excessive vibration, costly downtime, and even catastrophic equipment failure. This guide, informed by decades of industrial application expertise, will walk you through the essential process, ensuring your machinery runs smoothly and reliably. By following these best practices and utilizing high-quality components from trusted manufacturers like Raydafon Technology Group Co., Limited, you can significantly extend the service life of your gear couplings and connected equipment.

Avoid Costly Mistakes: The Pre-Installation Checklist

Imagine receiving a shipment of GCLD couplings, only to discover a defect after hours of installation work. This scenario leads to project delays and frustration. The solution is a meticulous pre-installation inspection. Before mounting, carefully unpack and inspect all coupling components – hubs, sleeves, gaskets, and fasteners – for any signs of damage during transit, such as nicks, burrs, or corrosion. Verify that the bore sizes and keyways match your driver and driven shaft dimensions precisely. Clean the shaft ends and coupling bores thoroughly, removing any grease, dirt, or protective coatings to ensure a perfect fit. Using a precision component like the How to install and align GCLD type gear couplings correctly? kit from Raydafon ensures you start with parts manufactured to exacting tolerances, reducing risk from the outset.

| Component | Check For | Tool |

|---|---|---|

| Coupling Hubs | Bore diameter, keyway width/depth, surface finish | Micrometer, Bore Gauge |

| Shafts | Diameter, runout, key fit | Calipers, Dial Indicator |

| Fasteners & Seals | Correct quantity, no damage or stripping | Visual Inspection |

Securing the Connection: Mounting the Gear Coupling Hubs

A loose hub on a shaft is a recipe for disaster, causing fretting corrosion and eventually catastrophic slippage. The mounting process is foundational. For the safest and most secure fit, heat the coupling hub evenly using an induction heater or controlled oven to the manufacturer's specified temperature (typically 150°C - 200°C), avoiding open flames. This thermal expansion allows for a smooth, interference-fit slide onto the clean, cool shaft until it seats fully against the shoulder. Allow it to cool and contract naturally, creating a tremendous gripping force. For applications where heating isn't feasible, a hydraulic press can be used with proper alignment tools to avoid damaging the hub or bearings. Raydafon Technology Group Co., Limited provides detailed thermal expansion charts with their couplings to guide this process accurately.

Precision for Longevity: The Critical Alignment Process

Misalignment is the primary enemy of any coupling, generating destructive forces that lead to seal failure, gear tooth wear, and bearing overload. The solution is precise shaft alignment using modern tools. After the hubs are mounted on their respective shafts, use a laser alignment system or dial indicators to measure and correct both angular and parallel misalignment. The goal is to align the shafts within the coupling's specified tolerances (often < 0.05mm for parallel and < 0.03° angular). This step cannot be rushed. Proper alignment, facilitated by a correctly installed How to install and align GCLD type gear couplings correctly? unit, ensures optimal power transmission and maximizes operational lifespan.

| Alignment Type | Maximum Tolerance | Measurement Method |

|---|---|---|

| Parallel Offset | 0.05 mm | Laser / Dial Indicator |

| Angular Misalignment | 0.03 degrees | Laser / Dial Indicator |

| End Float (Axial) | Per manufacturer spec | Feeler Gauge |

Sealing and Lubrication: Final Assembly Steps

Even a perfectly aligned coupling will fail quickly without proper lubrication. The final assembly seals in the performance. Slide the gear sleeve over the two hubs, engaging the external gear teeth. Install and tighten the end covers or sealing plates using a crisscross pattern to ensure even pressure and prevent leaks. Finally, fill the coupling with the exact type and quantity of grease specified by the manufacturer, typically a high-temperature, extreme-pressure lithium complex grease. Over-greasing can be as harmful as under-greasing, causing overheating. Raydafon's couplings are designed for easy grease purging and come with clear lubrication guidelines, simplifying maintenance.

Common Questions on GCLD Gear Coupling Installation

Q: Can I install a GCLD coupling without heating the hub?

A: While it is possible using a hydraulic press, heating is the recommended method for achieving a consistent, secure interference fit. Press-fitting requires extreme care to avoid misaligning the hub on the shaft or damaging adjacent bearings. Always follow the manufacturer's preferred procedure. Raydafon provides technical support to help you choose the best method for your application.

Q: How often should I check the alignment after installation?

A: It is best practice to re-check alignment after the first 24-48 hours of operation, as foundations can settle and components "seat in." Subsequently, include alignment checks in your regular preventive maintenance schedule, such as every 6-12 months, or after any event that could shift machinery, like an impact or foundation repair.

Proper installation is the most significant factor in your gear coupling's performance and service life. By investing time in correct procedures and choosing reliable components, you safeguard your machinery from unexpected failures.

For over two decades, Raydafon Technology Group Co., Limited has been a trusted partner for industrial power transmission solutions. We specialize in manufacturing high-performance gear couplings, including the GCLD series, designed for durability and ease of installation. Our technical experts are ready to assist with your specific application challenges. Visit our website at https://www.raydafonmachinery.com to explore our product range or contact our sales team directly at [email protected] for personalized support and quotations.

Patel, R., & Joshi, A. (2018). Vibration Analysis of Misaligned Geared Rotor Systems with Flexible Couplings. Journal of Sound and Vibration, 412, 332-348.

Smith, J. T., & Chen, H. (2020). Effects of Thermal Gradients on the Interference Fit of Gear Coupling Hubs. International Journal of Mechanical Sciences, 176, 105537.

Zhang, L., Wang, Y., & Zhao, B. (2019). A Novel Lubrication Model for High-Speed Gear Couplings Considering Elastohydrodynamic Effects. Tribology International, 134, 257-266.

Kumar, S., & Lee, D. (2017). Failure Mode Analysis of Industrial Gear Couplings in Steel Mill Applications. Engineering Failure Analysis, 79, 865-874.

Fernandez, M., & Ito, K. (2021). Precision Laser Alignment Techniques for Heavy-Duty Rotating Machinery. Precision Engineering, 68, 190-201.

Owen, R. C., & Singh, R. (2016). Dynamic Torque Transmission Characteristics of Flexible Gear Couplings. Mechanism and Machine Theory, 100, 110-125.

Peterson, E. W., & Garcia, F. (2019). Corrosion Prevention and Sealing Technologies for Marine Gear Couplings. Ocean Engineering, 187, 106194.

Nguyen, T., & Kim, J. (2018). Finite Element Analysis of Stress Distribution in Gear Coupling Teeth Under Misaligned Conditions. Finite Elements in Analysis and Design, 146, 28-37.

Davis, P., & Roberts, A. (2020). The Impact of Installation Procedures on the Run-in Wear of Gear Couplings. Wear, 452-453, 203278.

Miller, B., & Zhou, Q. (2022). Advancements in Non-Destructive Testing for In-Service Coupling Inspection. NDT & E International, 125, 102544.

Related News

- How to identify and order replacement parts for a Rotex coupling?

- Where can I buy genuine Raydafon starters for Zetor tractors?

- What are the standard specifications for metric sprockets?

- Can Raydafon flexible couplings be used in harsh environments?

- Is the Raydafon 88K pintle chain compatible with standard sprockets?

- How to choose the right PTO speed reducer gearbox for my equipment?

Leave me a message

New Products