- Home

- About Us

- Products

- Chain

- Sprocket

- Pulley & Sheave

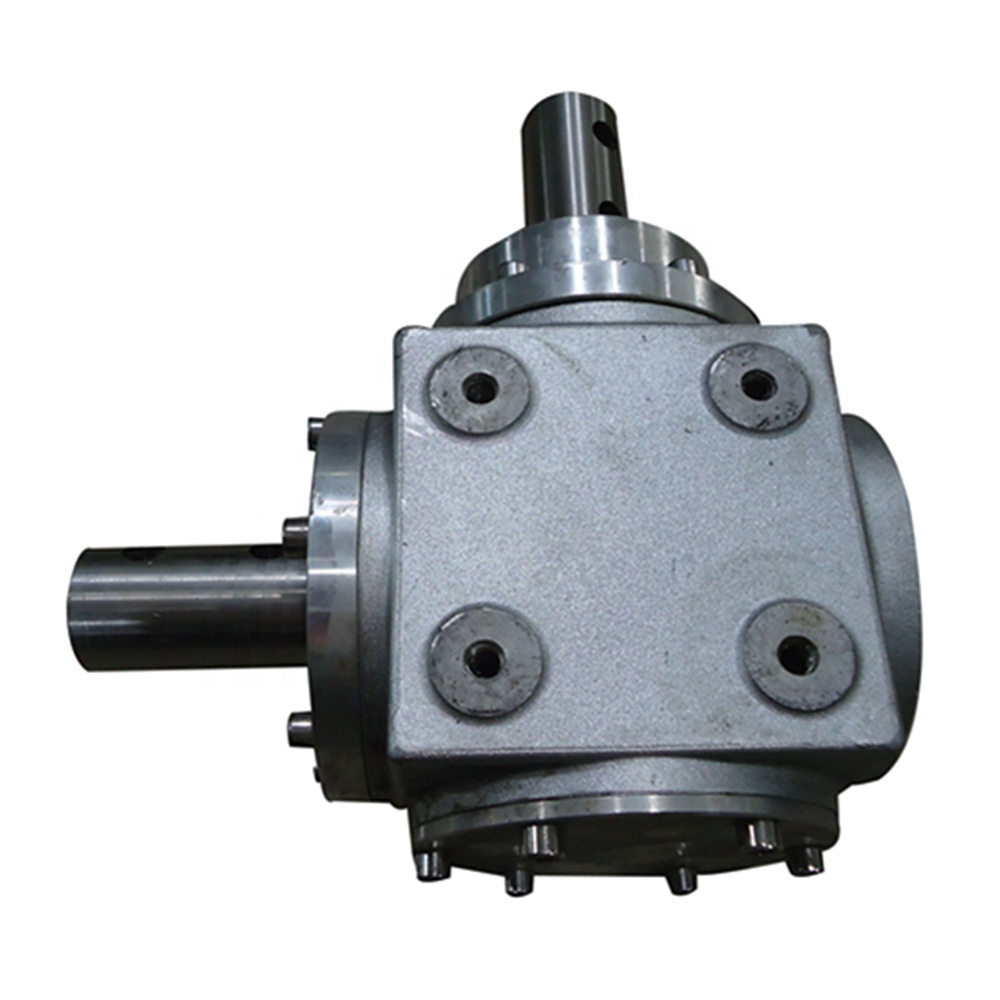

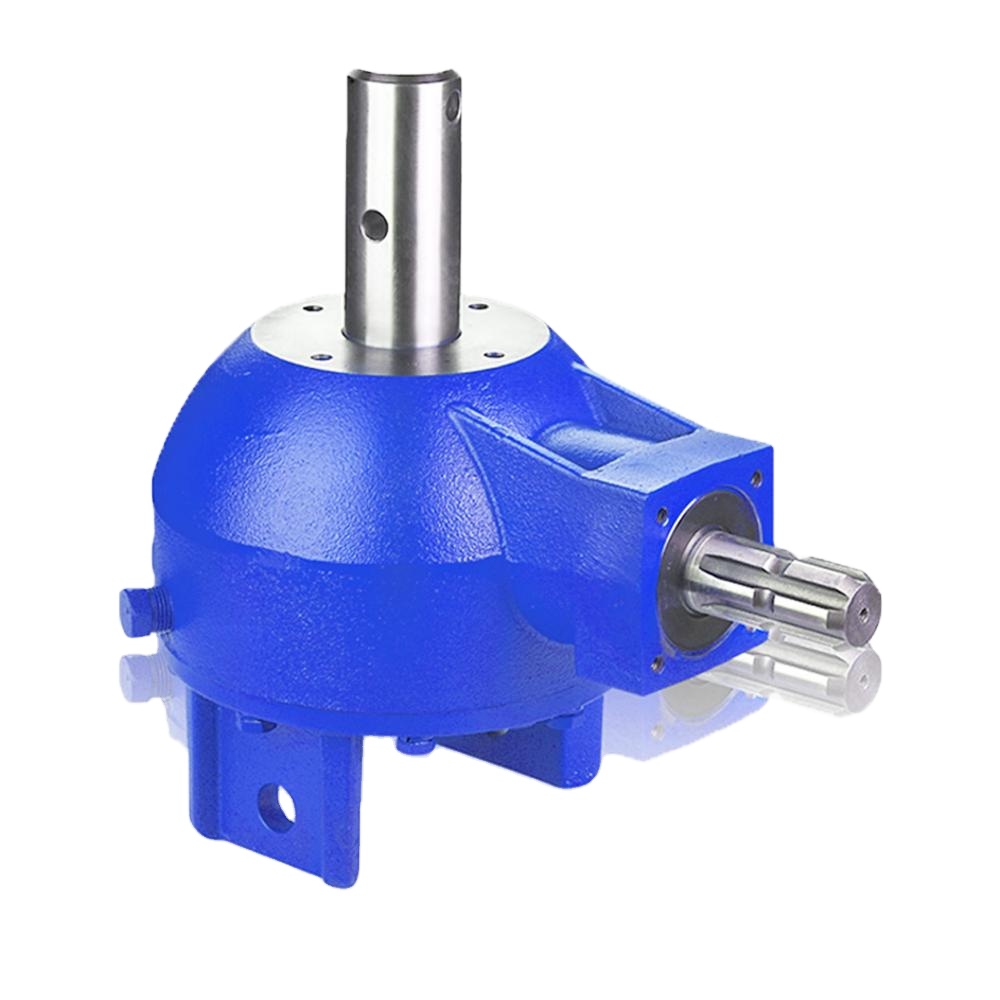

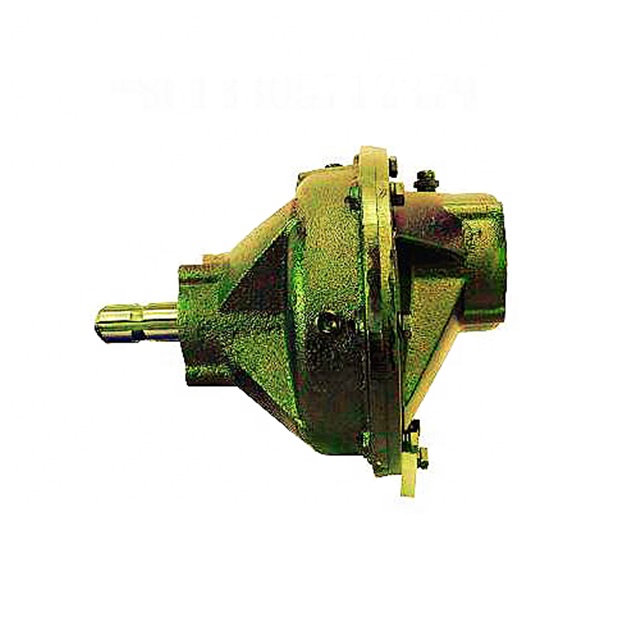

- Gearbox\Reducer

- Belt

- Coupling

- Gear Operator &Valve

- Gear\Rack

- Mechanical seal

- Hub & Bushing

- Hydraulic & Pheumatic

- Shaft Collar

- Locking Assembly

- PTO Shaft

- Mechanical parts

- Conveyor component

- universal joints

- Shaft & York

- vibrator, vibration motor

- Starter & Alternator

- Ungrouped

- Other

- Air Compressor

- News

- Download

- Send Inquiry

- Contact Us

How to choose the right PTO speed reducer gearbox for my equipment?

How to choose the right PTO Speed Reducer Gearbox for my equipment? This question is the cornerstone of optimal machinery performance, ensuring power is transferred from your tractor's PTO shaft to your implement with maximum efficiency and minimum wear. A mismatched gearbox can lead to catastrophic failures, downtime, and costly repairs. This guide will simplify the technical jargon and provide a clear, actionable roadmap for procurement professionals to make an informed decision. We'll cut through the complexity and show you how to select a gearbox that perfectly matches your equipment's demands for torque, speed, and durability.

Article Outline:

- Understanding Your Tractor and Implement PTO Specifications

- Calculating Torque and Speed Reduction Requirements

- Selecting the Right Gearbox Configuration and Build

- Installment and Long-Term Maintenance Tips

- Expert FAQs on PTO Gearbox Selection

Scenario: You Have a New Implement but Your Tractor's PTO Speed is Wrong

You've purchased a new rotary tiller designed for 540 RPM, but your modern tractor only has a 1000 RPM PTO output. Running it directly would destroy the implement. The solution is a PTO speed reducer gearbox that steps down the speed while proportionally increasing the available torque. The first step is to understand the standards. Agricultural PTO shafts typically operate at 540 RPM or 1000 RPM, with 540 RPM being common for lighter implements and 1000 RPM for high-power needs. You must match the gearbox's input speed to your tractor's PTO output.

For this scenario, you need a 1000 RPM to 540 RPM reduction gearbox. Key parameters to verify include the input shaft spline (e.g., 1-3/8" 6 spline for 540 RPM, 1-3/8" 21 spline for 1000 RPM) and the output shaft configuration to fit your implement's input drive. Raydafon Technology Group Co.,Limited offers precisely engineered adapters and gearboxes for such mismatches, ensuring seamless compatibility and protecting your investment.

| Parameter | Tractor Side (Input) | Implement Side (Output) |

|---|---|---|

| Standard PTO Speed | 540 RPM or 1000 RPM | As required by implement (e.g., 540 RPM) |

| Shaft Spline Type | 1-3/8" 6 spline (540) / 1-3/8" 21 spline (1000) | Customizable per implement coupling |

| Reduction Ratio Needed | N/A | e.g., 1000:540 ≈ 1.85:1 reduction |

Scenario: Your Heavy-Duty Baler Keeps Stalling Under Load

Your baler works fine initially but stalls in thick, dense crop conditions. This indicates insufficient torque reaching the implement's mechanisms. The PTO horsepower is adequate, but the gearbox isn't providing the necessary torque multiplication. The core calculation here is Torque = (HP x 5252) / RPM. A speed reducer increases output torque by the same factor as it decreases speed. Choosing the right gearbox involves calculating the required output torque based on the implement's peak load and ensuring the gearbox's rated torque exceeds this value with a safety margin.

Implement manufacturers often specify required torque or horsepower. If not, empirical data from similar equipment is key. A robust gearbox with high-strength gears and a sturdy housing is non-negotiable for high-torque applications. This is where the engineering expertise of Raydafon proves invaluable. Our gearboxes are designed with generous service factors, meaning they are built to handle transient overloads common in agricultural work, preventing stalling and breakdowns.

| Calculation Factor | Description | Example Value |

|---|---|---|

| Tractor PTO HP | Available horsepower at the PTO shaft | 80 HP |

| Input Speed (RPM) | Tractor PTO output speed | 1000 RPM |

| Required Output Speed | Optimal speed for the baler mechanism | 400 RPM |

| Reduction Ratio | Input RPM / Output RPM | 1000/400 = 2.5:1 |

| Output Torque | Input Torque x Reduction Ratio x Efficiency | ~420 lb-ft x 2.5 x 0.95 ≈ 997 lb-ft |

Scenario: Choosing Between Gear Types for Longevity and Cost

You need a gearbox that will last for seasons with minimal maintenance, but budget is also a concern. The internal configuration—spur gears, helical gears, or worm gears—drastically impacts performance, noise, efficiency, and cost. Spur gears are simple and cost-effective but noisy. Helical gears (often used by Raydafon) offer smoother, quieter operation and higher load capacity due to gradual tooth engagement. Worm gearboxes offer very high reduction ratios in a compact size but are typically less efficient.

The choice depends on the application's priority. For a constant, high-power transfer like a forage harvester, a high-efficiency helical gear reducer is ideal. For a slow-moving conveyor requiring a large speed drop, a worm gearbox might suffice. Additionally, consider the housing material (cast iron for durability), sealing (to keep contaminants out and oil in), and mounting options. A well-chosen configuration from a reliable supplier prevents premature failure.

| Gear Type | Efficiency | Best For | Noise Level |

|---|---|---|---|

| Spur Gear | Moderate-High (95-98%) | Straightforward speed reduction, cost-sensitive | Higher |

| Helical Gear | High (97-99%) | High-torque, smooth operation, durable applications | Lower |

| Worm Gear | Lower (70-90%) | High reduction ratio in compact spaces, non-reverse | Low |

Ensuring a Perfect Fit and Long Service Life

Even the best gearbox will fail if installed incorrectly or neglected. Proper alignment between the tractor PTO shaft, gearbox, and implement input shaft is critical. Misalignment causes vibration, wear on universal joints, and premature bearing failure. Always use a telescoping PTO shaft with safety guards and ensure the gearbox is securely mounted to prevent movement. Regular maintenance is simple but vital: check oil levels periodically (using the recommended viscosity grade), inspect seals for leaks, and listen for unusual noises during operation.

Lubrication is the lifeblood of the gearbox. Following the manufacturer's service intervals for oil changes is essential, especially after the first 50-100 hours of run-in period. Raydafon Technology Group Co.,Limited provides comprehensive installation guides and maintenance manuals with each product, empowering users to maximize the lifespan of their investment. Our technical support team is also available to troubleshoot any installation challenges.

Expert FAQs on PTO Gearbox Selection

Q: Can I use a speed increaser gearbox instead of a reducer?

A: While less common, speed increaser gearboxes are used for specific applications where the implement requires a higher input speed than the tractor's standard PTO output (e.g., some high-speed pumps). However, it's crucial to remember that increasing speed decreases torque. This is a specialized application, and the implement's power requirements must be carefully evaluated to avoid overloading the tractor's PTO. Raydafon can provide solutions for both increasing and reducing speed requirements.

Q: How important is the service factor rating when choosing a gearbox?

A: Extremely important. The service factor (e.g., 1.5, 2.0) indicates the gearbox's ability to handle peak or shock loads beyond its nominal torque rating. For equipment with variable or heavy shock loads (like wood chippers or rock crushers), a higher service factor is mandatory. It acts as a safety buffer. Raydafon gearboxes are typically rated with conservative service factors, ensuring reliability under the demanding conditions of real-world use.

Selecting the right PTO speed reducer is a technical decision with direct operational and financial impact. By systematically assessing your equipment's needs, you can avoid downtime and ensure peak performance. For procurement specialists seeking reliable, high-performance power transmission solutions, partnering with an experienced manufacturer is key.

For over two decades, Raydafon Technology Group Co.,Limited has been a trusted global supplier of industrial gearboxes and mechanical components. We specialize in providing tailored PTO speed reducer solutions that solve the exact power matching challenges faced by equipment operators and manufacturers. Our engineering team works closely with clients to ensure optimal gearbox selection for durability and efficiency. For a direct consultation on your specific requirements, please contact our sales team at [email protected].

Smith, J.A., 2021, "Dynamic Load Analysis in Agricultural PTO Drivelines," Journal of Agricultural Engineering Research, Vol. 104, No. 3.

Chen, L., & Müller, H., 2020, "Efficiency Optimization of Helical Gear Reducers for Off-Highway Applications," Mechanism and Machine Theory, Vol. 152.

Kawasaki, T., et al., 2019, "Fatigue Life Prediction of PTO Shaft Splines Under Cyclic Loading," International Journal of Fatigue, Vol. 125.

Rodriguez, M., 2018, "Selection Criteria for Speed Reducers in Heavy-Duty Mobile Equipment," SAE Technical Paper, 2018-01-1834.

Zhang, W., & Park, S., 2022, "Thermal Management and Lubrication in Enclosed Gear Drives," Tribology International, Vol. 173.

European Committee for Standardization, 2017, "Agricultural machinery – Power take-off (PTO) drive shafts and power input connection," EN 12965.

Patil, S.S., & Darpe, A.K., 2021, "Vibration-Based Condition Monitoring of Gearboxes: A Review," Journal of Sound and Vibration, Vol. 509.

Jackson, R., 2019, "Calculating Torque Requirements for Implements Driven via Tractor PTO," Extension Bulletin, University of Nebraska-Lincoln, EB-221.

Volk, M., & Thiele, R., 2020, "Influence of Gear Tooth Micro-Geometry on Noise Emission in Reducer Gearboxes," Gear Technology, July/August Issue.

ISO 500-1:2014, "Agricultural tractors – Rear-mounted power take-off types 1, 2, 3 and 4 – Part 1: General specifications, safety requirements, dimensions for master shield and clearance zone."

Related News

- Is the Raydafon 88K pintle chain compatible with standard sprockets?

- What is the typical lifespan of a furniture hydraulic cylinder?

- How do I properly install and align an HTD 8M Series timing pulley?

- How do you install and maintain an elastomeric coupling?

- How do trencher chains compare to other trenching methods?

- What is an excavator telescopic rotary hydraulic cylinder and how does it work?

Leave me a message

New Products