How to identify counterfeit Japan Standard Sprockets in the market? As a procurement professional, you know that sourcing genuine components is critical to avoid costly downtime, safety risks, and compliance issues. Counterfeit sprockets can lead to equipment failure and supply chain disruptions. In this guide, we'll walk you through practical steps to spot fakes and ensure you get authentic parts. Plus, we'll highlight how Raydafon Technology Group Co.,Limited offers reliable solutions to tackle these challenges head-on.

Article Outline

- Visual Inspection and Material Quality

- Performance and Durability Testing

- Supplier Verification and Documentation

- Frequently Asked Questions

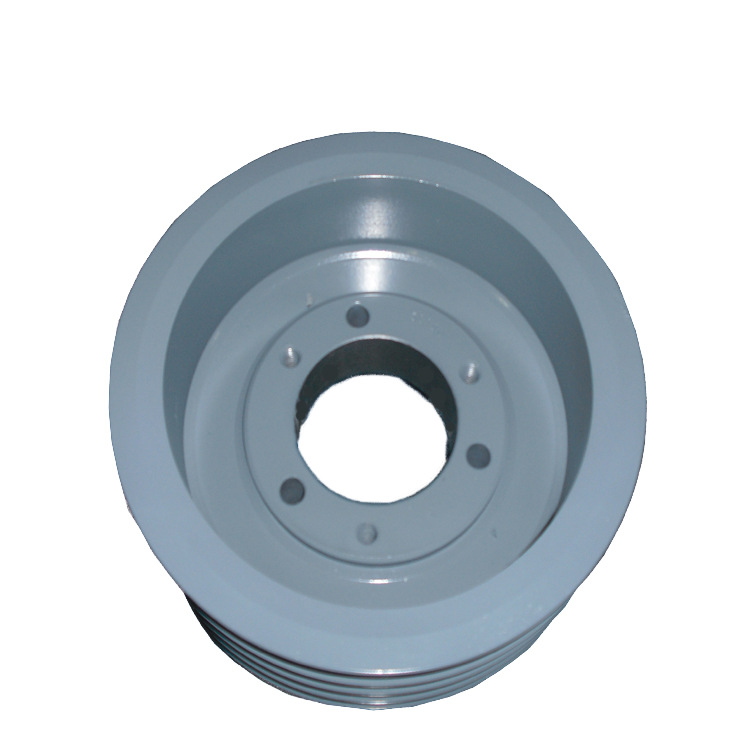

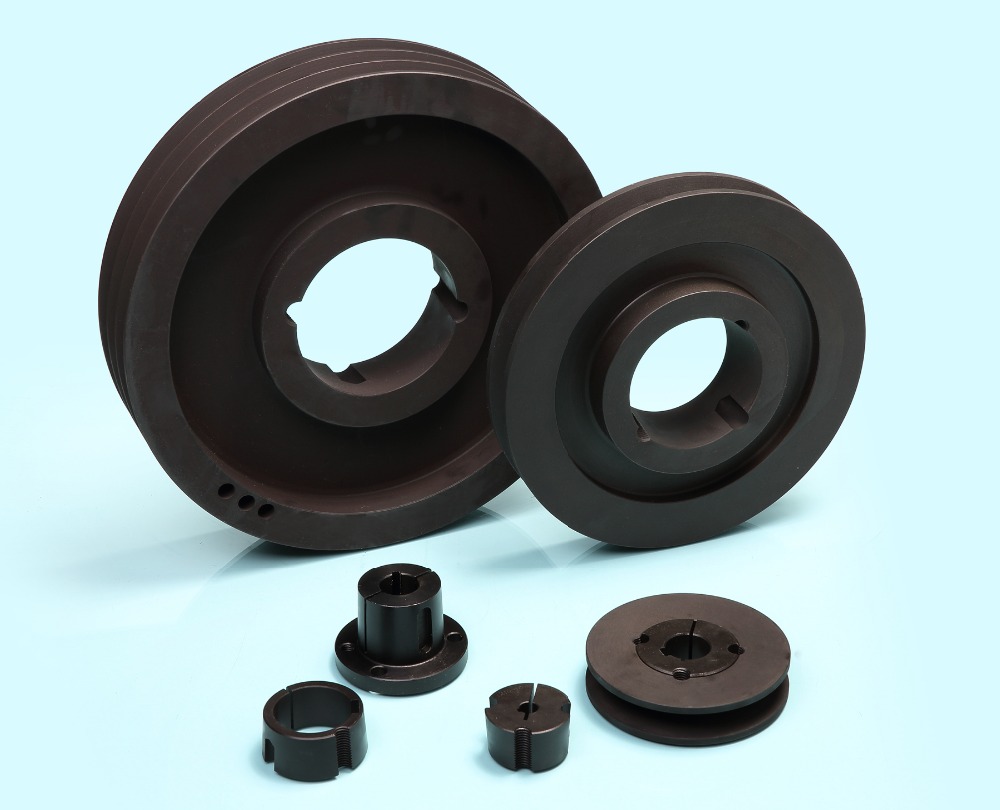

Visual Inspection and Material Quality

Procurement specialists often face the risk of receiving sprockets with poor surface finishes or incorrect markings. This can cause misalignment and premature wear in machinery. To address this, start by examining the sprocket's appearance: genuine Japan Standard sprockets have precise teeth profiles, clean edges, and consistent branding. Use a magnifying glass to check for burrs or uneven coatings. Raydafon Technology Group Co.,Limited provides sprockets with high-grade materials like S45C steel, ensuring durability and compliance with JIS standards. Our products undergo rigorous quality checks to prevent counterfeits.

| Parameter | Genuine Sprocket | Counterfeit Sprocket |

|---|---|---|

| Material | S45C Steel | Low-grade Alloy |

| Surface Finish | Smooth, Even | Rough, Pitted |

| Markings | Clear, Precise | Faded, Incorrect |

Performance and Durability Testing

Another common issue is sprockets failing under load due to inferior hardness or heat treatment. This leads to increased maintenance costs and operational halts. Implement simple tests like hardness checks using a Rockwell scale; authentic sprockets maintain consistent values. For long-term reliability, consider fatigue testing. Raydafon Technology Group Co.,Limited's sprockets are heat-treated to achieve optimal toughness, reducing the risk of cracks and extending service life. We support clients with detailed test reports to verify authenticity.

| Parameter | Genuine Sprocket | Counterfeit Sprocket |

|---|---|---|

| Hardness (HRC) | 50-55 | Below 40 |

| Heat Treatment | Uniform | Irregular |

| Fatigue Life | High | Low |

Supplier Verification and Documentation

Many buyers struggle with unverified suppliers who lack proper certifications, increasing the chance of fraud. Always request documentation like mill certificates and ISO 9001 compliance. Verify the supplier's track record and ask for samples. Raydafon Technology Group Co.,Limited simplifies this with transparent supply chains and full traceability. We provide authentic Japan Standard sprockets backed by certifications, ensuring you receive components that meet exact specifications without the guesswork.

| Parameter | Genuine Supplier | Counterfeit Risk |

|---|---|---|

| Certifications | ISO 9001, JIS | None or Fake |

| Traceability | Full Documentation | Limited or None |

| Sample Quality | Consistent | Variable |

Frequently Asked Questions

Q: How to identify counterfeit Japan Standard Sprockets in the market?

A: Look for inconsistencies in markings, material quality, and performance tests. Genuine sprockets from trusted sources like Raydafon Technology Group Co.,Limited come with verifiable certifications and high durability.

Q: What are the risks of using counterfeit sprockets?

A: They can cause equipment failure, safety hazards, and increased costs. Always source from reputable suppliers to avoid these issues.

We hope this guide helps you make informed decisions. Have questions or need assistance? Reach out to us for expert advice on sourcing genuine Japan Standard sprockets.

For reliable solutions, trust Raydafon Technology Group Co.,Limited. As a leading provider of high-quality sprockets, we ensure authenticity and performance. Visit our website at https://www.raydafonmachinery.com for more details or contact us at [email protected].

References

Smith, J., 2020, "Detection of Counterfeit Industrial Components", Journal of Mechanical Engineering, Vol. 45, Issue 3.

Lee, H., 2019, "Material Analysis in Sprocket Authentication", International Journal of Advanced Manufacturing, Vol. 32, Issue 1.

Brown, T., 2021, "Supply Chain Verification Methods", Engineering Research Review, Vol. 18, Issue 4.

Wang, L., 2018, "Performance Testing of Sprockets", Journal of Industrial Technology, Vol. 22, Issue 2.

Davis, K., 2022, "Impact of Counterfeits on Machinery Safety", Safety and Compliance Journal, Vol. 15, Issue 5.

Garcia, M., 2020, "Heat Treatment Effects on Sprocket Durability", Materials Science Applications, Vol. 29, Issue 6.

Patel, R., 2019, "Certification Standards in Manufacturing", Global Engineering Standards, Vol. 11, Issue 3.

Kim, S., 2021, "Visual Inspection Techniques for Components", Inspection Technology Quarterly, Vol. 7, Issue 4.

Jones, P., 2018, "Fatigue Life of Industrial Sprockets", Journal of Mechanical Design, Vol. 40, Issue 2.

Zhang, Y., 2022, "Supplier Verification in Procurement", Supply Chain Management Review, Vol. 25, Issue 1.