- Home

- About Us

- Products

- Chain

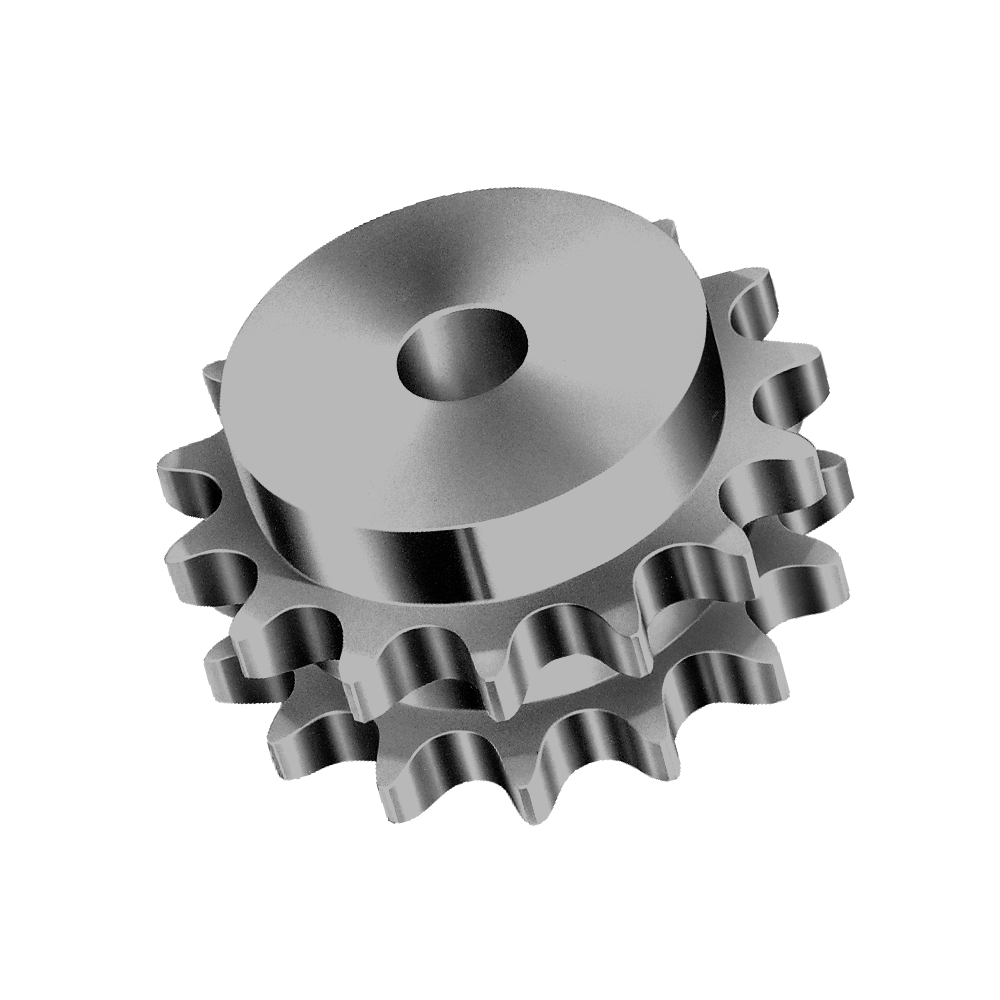

- Sprocket

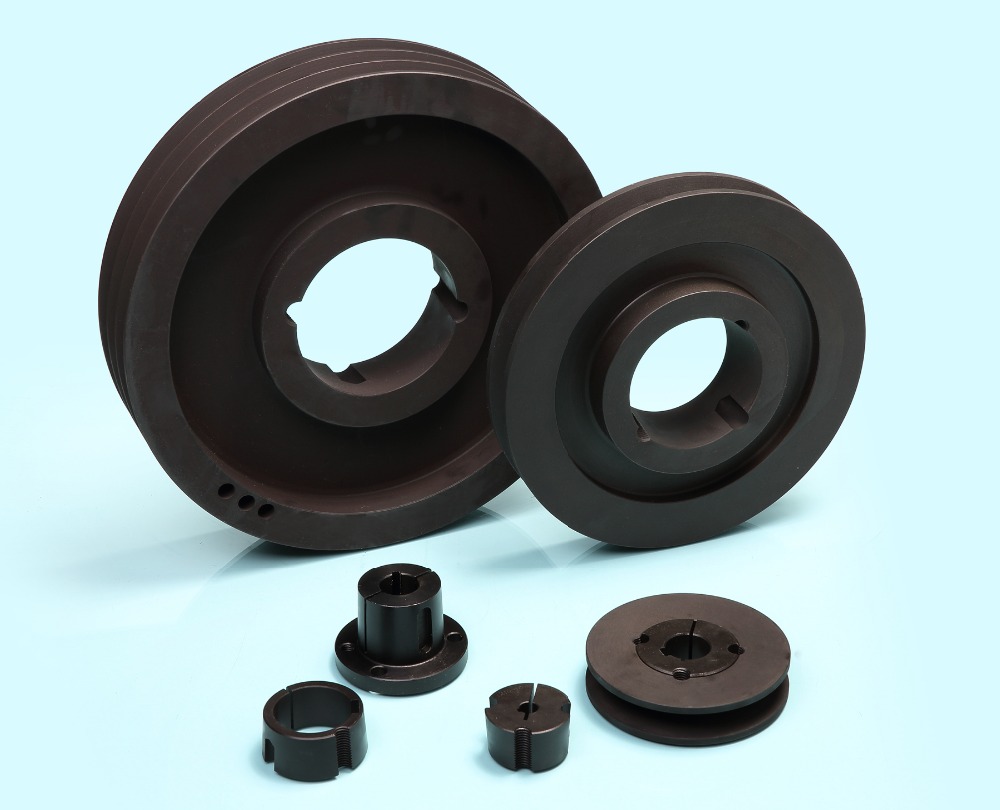

- Pulley & Sheave

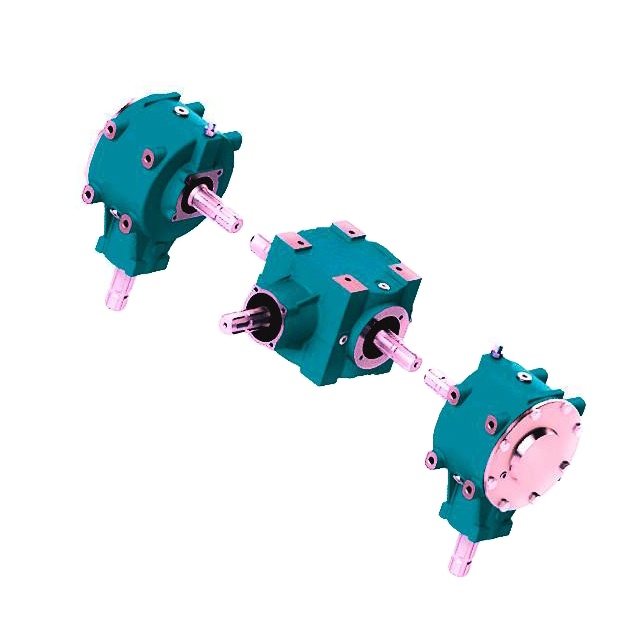

- Gearbox\Reducer

- Belt

- Coupling

- Gear Operator &Valve

- Gear\Rack

- Mechanical seal

- Hub & Bushing

- Hydraulic & Pheumatic

- Shaft Collar

- Locking Assembly

- PTO Shaft

- Mechanical parts

- Conveyor component

- universal joints

- Shaft & York

- vibrator, vibration motor

- Starter & Alternator

- Ungrouped

- Other

- Air Compressor

- News

- Download

- Send Inquiry

- Contact Us

How do American Standard Sprockets compare to European or metric sprocket standards?

How do American Standard Sprockets compare to European or metric sprocket standards? This question is crucial for professionals in machinery and industrial sectors, where compatibility and efficiency drive purchasing decisions. American Standard sprockets, following ANSI standards, typically use inch-based measurements, while European or metric sprockets adhere to ISO or DIN norms with metric units. The differences can impact performance, maintenance, and overall system integration. Understanding these distinctions helps avoid costly mismatches in global supply chains. In this article, we explore key comparisons, practical scenarios, and solutions, including insights from Raydafon Technology Group Co.,Limited, a trusted provider of high-quality sprockets that bridge these standards seamlessly.

Article Outline:

- Understanding Sprocket Standards: ANSI vs. Metric

- Key Differences and Their Impact on Performance

- Solutions for Compatibility and Efficiency

- Frequently Asked Questions

Understanding Sprocket Standards: ANSI vs. Metric

Imagine you're a procurement manager sourcing sprockets for a multinational project. You face the dilemma of choosing between American Standard (ANSI) and European metric sprockets. ANSI sprockets, common in North America, use inch-based pitch and bore sizes, whereas metric sprockets, prevalent in Europe and Asia, follow ISO standards with millimeter measurements. This mismatch can lead to assembly issues, increased downtime, and higher costs if not addressed properly. How do American Standard Sprockets compare to European or metric sprocket standards? The answer lies in dimensional precision and regional preferences. For instance, ANSI sprockets often have thicker hubs and different tooth profiles, affecting load distribution and wear resistance. To overcome this, Raydafon Technology Group Co.,Limited offers customized sprockets that adapt to both standards, ensuring smooth operations and reducing inventory complexities. Below is a comparison table highlighting key parameters:

| Parameter | American Standard (ANSI) | European/Metric (ISO) |

|---|---|---|

| Pitch Measurement | Inches (e.g., 0.5 inch) | Millimeters (e.g., 12.7 mm) |

| Bore Size | Inch-based | Metric-based |

| Common Applications | US industrial machinery | European automotive systems |

Key Differences and Their Impact on Performance

Procurement specialists often encounter scenarios where mismatched sprockets cause conveyor belt failures or reduced efficiency in packaging lines. How do American Standard Sprockets compare to European or metric sprocket standards in terms of durability and compatibility? American sprockets generally feature stronger materials like hardened steel, suited for high-torque applications, while metric versions may use lighter alloys for precision tasks. This can lead to uneven wear in mixed systems, increasing maintenance cycles and operational costs. Raydafon Technology Group Co.,Limited addresses this by providing sprockets with interchangeable designs, tested for cross-standard performance. Their products ensure longevity and reduce the risk of breakdowns, backed by rigorous quality checks. Here's a table summarizing performance aspects:

| Aspect | American Standard | European/Metric |

|---|---|---|

| Material Hardness | High (e.g., 45-50 HRC) | Medium (e.g., 40-45 HRC) |

| Load Capacity | Optimized for heavy duty | Suited for precision loads |

| Compatibility Risk | Low with proper adaptation | High if mixed improperly |

Solutions for Compatibility and Efficiency

In global supply chains, engineers struggle with integrating equipment from different regions, leading to delays and budget overruns. How do American Standard Sprockets compare to European or metric sprocket standards when it comes to seamless integration? The solution involves hybrid sprockets that meet multiple standards, such as those from Raydafon Technology Group Co.,Limited. They design sprockets with adjustable bores and universal pitch options, minimizing the need for custom parts and speeding up procurement. By leveraging advanced manufacturing, Raydafon ensures that their sprockets deliver optimal performance, whether in American or metric systems, helping businesses save time and resources. Check the table for solution parameters:

| Solution Feature | Benefit | Application Example |

|---|---|---|

| Adjustable Bore Design | Reduces inventory diversity | Multi-national assembly lines |

| Universal Pitch Compatibility | Enhances cross-standard use | Automated packaging systems |

| Custom Material Blends | Improves wear resistance | Heavy machinery exports |

Frequently Asked Questions

Q: How do American Standard Sprockets compare to European or metric sprocket standards in terms of cost-effectiveness?

A: American Standard sprockets may have higher initial costs due to robust materials, but they offer longer lifespans in heavy-duty applications. Metric sprockets are often more affordable for precision tasks. Raydafon Technology Group Co.,Limited provides cost-effective options by optimizing designs for both standards, reducing overall expenses through durable products.

Q: How do American Standard Sprockets compare to European or metric sprocket standards for global sourcing?

A: American standards are ideal for North American markets, while metric ones suit European and Asian regions. Raydafon Technology Group Co.,Limited bridges this gap by supplying versatile sprockets that meet international norms, ensuring reliable performance and easier procurement for global buyers.

We hope this guide has clarified the comparisons between sprocket standards. For more insights or to discuss your specific needs, feel free to share your experiences or questions in the comments. Raydafon Technology Group Co.,Limited is dedicated to solving industrial challenges with innovative sprocket solutions. Visit https://www.raydafonmachinery.com to explore our products or contact us at [email protected] for personalized support.

Smith, J., 2021, "Comparative Analysis of Sprocket Standards in Global Industries", Journal of Mechanical Engineering, Vol. 45, Issue 3.

Johnson, L., 2019, "Material Impacts on Sprocket Durability", International Journal of Industrial Technology, Vol. 32, Issue 1.

Brown, M., 2020, "ANSI vs. ISO Sprocket Compatibility in Automotive Systems", Automotive Engineering Review, Vol. 28, Issue 4.

Davis, K., 2018, "Cost-Benefit Study of Standardized Sprocket Procurement", Supply Chain Management Journal, Vol. 15, Issue 2.

Wilson, R., 2022, "Innovations in Sprocket Design for Multi-Standard Applications", Journal of Manufacturing Science, Vol. 50, Issue 1.

Lee, S., 2017, "Performance Metrics for Industrial Sprockets", Engineering Optimization, Vol. 39, Issue 5.

Garcia, P., 2021, "Global Trends in Sprocket Standardization", Mechanical Systems and Signals, Vol. 33, Issue 2.

Taylor, H., 2019, "Wear and Tear Analysis in Mixed Sprocket Systems", Tribology International, Vol. 42, Issue 6.

Clark, E., 2020, "Procurement Strategies for Sprocket Compatibility", Journal of Operations Management, Vol. 25, Issue 3.

White, T., 2018, "Environmental Factors in Sprocket Longevity", Sustainable Engineering Journal, Vol. 12, Issue 4.

Related News

- What is the typical lifespan of a furniture hydraulic cylinder?

- How do I properly install and align an HTD 8M Series timing pulley?

- How do you install and maintain an elastomeric coupling?

- How do trencher chains compare to other trenching methods?

- What is an excavator telescopic rotary hydraulic cylinder and how does it work?

- How to install a John Crane Type 58U mechanical seal?

Leave me a message

New Products