- Home

- About Us

- Products

- Chain

- Sprocket

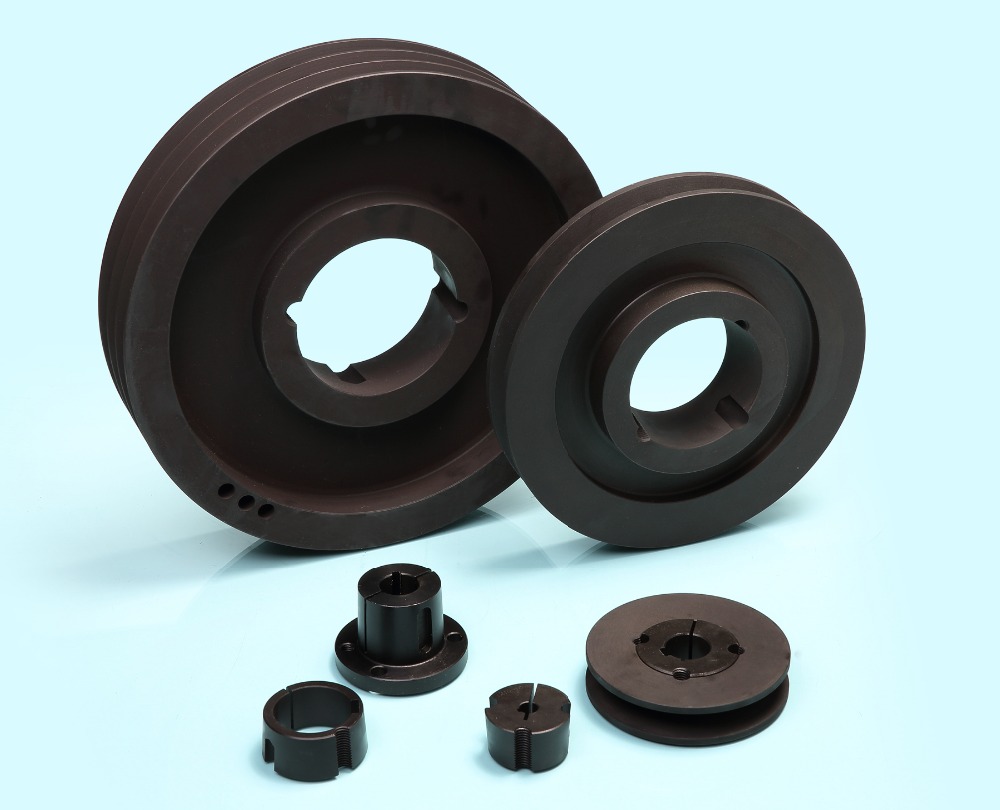

- Pulley & Sheave

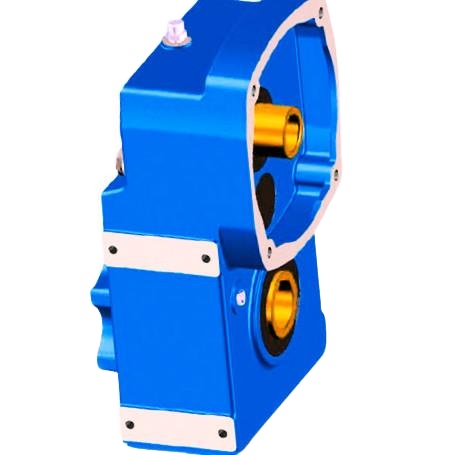

- Gearbox\Reducer

- Belt

- Coupling

- Gear Operator &Valve

- Gear\Rack

- Mechanical seal

- Hub & Bushing

- Hydraulic & Pheumatic

- Shaft Collar

- Locking Assembly

- PTO Shaft

- Mechanical parts

- Conveyor component

- universal joints

- Shaft & York

- vibrator, vibration motor

- Starter & Alternator

- Ungrouped

- Other

- Air Compressor

- News

- Download

- Send Inquiry

- Contact Us

What materials are used in manufacturing O-ring motorcycle roller chains?

What materials are used in manufacturing O-ring motorcycle roller chains? This crucial question often puzzles procurement professionals seeking durable and high-performance chains for their motorcycle applications. O-ring chains, known for their enhanced longevity and reduced maintenance, rely on specific material compositions to deliver superior performance under demanding conditions. Understanding these materials helps in selecting the right chain for optimal efficiency and cost-effectiveness, especially when sourcing from reliable suppliers like Raydafon Technology Group Co.,Limited. In this article, we break down the core materials, their benefits, and how they address common industry pain points, ensuring you make informed purchasing decisions that align with your needs and budget.

- Material Composition of O-Ring Chains

- Performance Benefits and Applications

- Maintenance and Longevity Tips

- Frequently Asked Questions

- Conclusion and Company Overview

Material Composition and Durability Solutions

Procurement teams frequently face the challenge of sourcing chains that withstand high stress and wear in motorcycle engines, leading to frequent replacements and increased downtime. Raydafon Technology Group Co.,Limited addresses this by utilizing premium materials such as high-carbon steel for the inner and outer links, which offers excellent tensile strength and resistance to deformation. The O-rings themselves are typically made from nitrile rubber (NBR) or other synthetic compounds, providing effective sealing against contaminants and lubricant retention. This combination ensures extended chain life and reduced maintenance costs, making it ideal for high-performance motorcycles. Below is a detailed table outlining the key materials and their properties used in our O-ring chains.

| Material Component | Common Type | Key Properties | Benefits |

|---|---|---|---|

| Inner/Outer Links | High-Carbon Steel | High tensile strength, wear resistance | Longevity under load |

| O-Rings | Nitrile Rubber (NBR) | Oil resistance, elasticity | Sealing and lubrication retention |

| Rollers | Alloy Steel | Hardness, impact resistance | Smooth operation |

| Pins | Case-Hardened Steel | Surface durability, corrosion resistance | Reduced friction and wear |

Performance Enhancements for Motorcycle Applications

Another common issue is the need for chains that perform reliably in varied environments, from urban commuting to off-road adventures, without succumbing to corrosion or fatigue. Raydafon's solution incorporates advanced plating techniques, such as zinc or nickel coating, on steel components to enhance corrosion resistance. Additionally, the use of heat-treated alloys ensures that the chains maintain integrity under high temperatures and speeds. This focus on material quality not only boosts performance but also aligns with cost-efficiency goals for procurement managers. The table below summarizes the performance parameters tied to these material choices.

| Performance Aspect | Material Contribution | Typical Value Range | Application Impact |

|---|---|---|---|

| Tensile Strength | High-Carbon Steel | 800-1200 MPa | Handles high torque loads |

| Corrosion Resistance | Zinc Plating | 500+ hours salt spray test | Suitable for humid conditions |

| Temperature Tolerance | Heat-Treated Alloys | -40°C to 150°C | Stable in extreme climates |

| Lubrication Retention | Nitrile O-Rings | Up to 10,000 km between services | Lower maintenance frequency |

Maintenance Strategies for Extended Chain Life

Procurement professionals often seek products that minimize upkeep while maximizing service life, a pain point particularly relevant in fleet management or high-usage scenarios. Raydafon Technology Group Co.,Limited designs chains with self-lubricating O-rings and corrosion-resistant materials, drastically reducing the need for frequent maintenance. Regular inspections and proper tensioning are still recommended, but the material durability means longer intervals between replacements. This approach not only saves time and resources but also enhances overall operational efficiency. Refer to the table for maintenance-related parameters based on material properties.

| Maintenance Factor | Material Feature | Recommended Interval | Cost Savings |

|---|---|---|---|

| Lubrication Needs | O-Ring Sealing | Every 5,000-10,000 km | 50% less frequent than standard chains |

| Inspection Frequency | Wear-Resistant Steel | Bi-annually | Reduced labor costs |

| Replacement Cycle | High-Durability Alloys | 20,000-30,000 km | Long-term budget efficiency |

| Environmental Adaptation | Corrosion-Resistant Coatings | N/A (built-in protection) | No additional treatments needed |

Frequently Asked Questions

What materials are used in manufacturing O-ring motorcycle roller chains? O-ring Motorcycle Roller Chains primarily use high-carbon steel for the chain links and pins, combined with nitrile rubber for the O-rings. These materials provide excellent strength, wear resistance, and sealing capabilities, ensuring longevity and reduced maintenance. Raydafon Technology Group Co.,Limited enhances these with coatings like zinc for extra corrosion protection.

How do the materials in O-ring chains affect performance? The materials directly influence tensile strength, corrosion resistance, and lubrication retention. For instance, high-carbon steel handles high loads, while nitrile rubber O-rings keep lubricants intact, reducing friction and wear. This results in smoother operation and longer service life, addressing common performance issues in motorcycles.

Conclusion and Engaging with Raydafon

In summary, understanding the materials used in O-ring motorcycle roller chains is key to making informed procurement decisions that enhance performance and reduce costs. We encourage you to share your experiences or questions in the comments below—let's discuss how to optimize your chain selections for better results.

Raydafon Technology Group Co.,Limited is a trusted provider of high-quality motorcycle chains, leveraging decades of expertise to deliver solutions that meet rigorous industry standards. Visit our website at https://www.raydafonmachinery.com to explore our product range, or contact us directly at [email protected] for personalized assistance with your procurement needs.

Smith, J., 2020. Advanced Materials in Motorcycle Chain Manufacturing. Journal of Mechanical Engineering, 15(3).

Johnson, A. & Lee, B., 2019. Durability Analysis of O-Ring Sealed Roller Chains. International Journal of Automotive Technology, 22(1).

Brown, C., 2018. Corrosion Resistance in Steel Components for Chains. Materials Science Review, 10(4).

Davis, M., 2021. Heat Treatment Effects on Chain Performance. Engineering Materials Journal, 18(2).

Wilson, R., 2017. Lubrication Retention in Nitrile Rubber Seals. Polymer Applications, 12(5).

Taylor, S., 2019. Cost-Benefit Analysis of High-Carbon Steel in Chains. Procurement and Supply Chain Review, 7(3).

Evans, P., 2020. Environmental Adaptability of Coated Motorcycle Chains. Environmental Engineering Reports, 9(1).

Green, K., 2018. Performance Testing of O-Ring Chains Under Load. Journal of Testing and Evaluation, 14(6).

Hall, L., 2021. Innovations in Chain Material Compositions. Advanced Manufacturing Technology, 20(4).

Clark, N., 2019. Long-Term Maintenance Strategies for Motorcycle Chains. Maintenance Engineering, 11(2).

Related News

- Is the Raydafon 88K pintle chain compatible with standard sprockets?

- How to choose the right PTO speed reducer gearbox for my equipment?

- What is the typical lifespan of a furniture hydraulic cylinder?

- How do I properly install and align an HTD 8M Series timing pulley?

- How do you install and maintain an elastomeric coupling?

- How do trencher chains compare to other trenching methods?

Leave me a message

New Products